Tamworth cutting tool manufacturer Industrial Tooling Corporation (ITC) has further enhanced its world-leading portfolio of bore machining products with the expansion of the BIG KAISER EWN Monoblock range. As the UK technology partner for BIG KAISER, the new additions to the EWN Monoblock range will improve productivity and performance for end users.

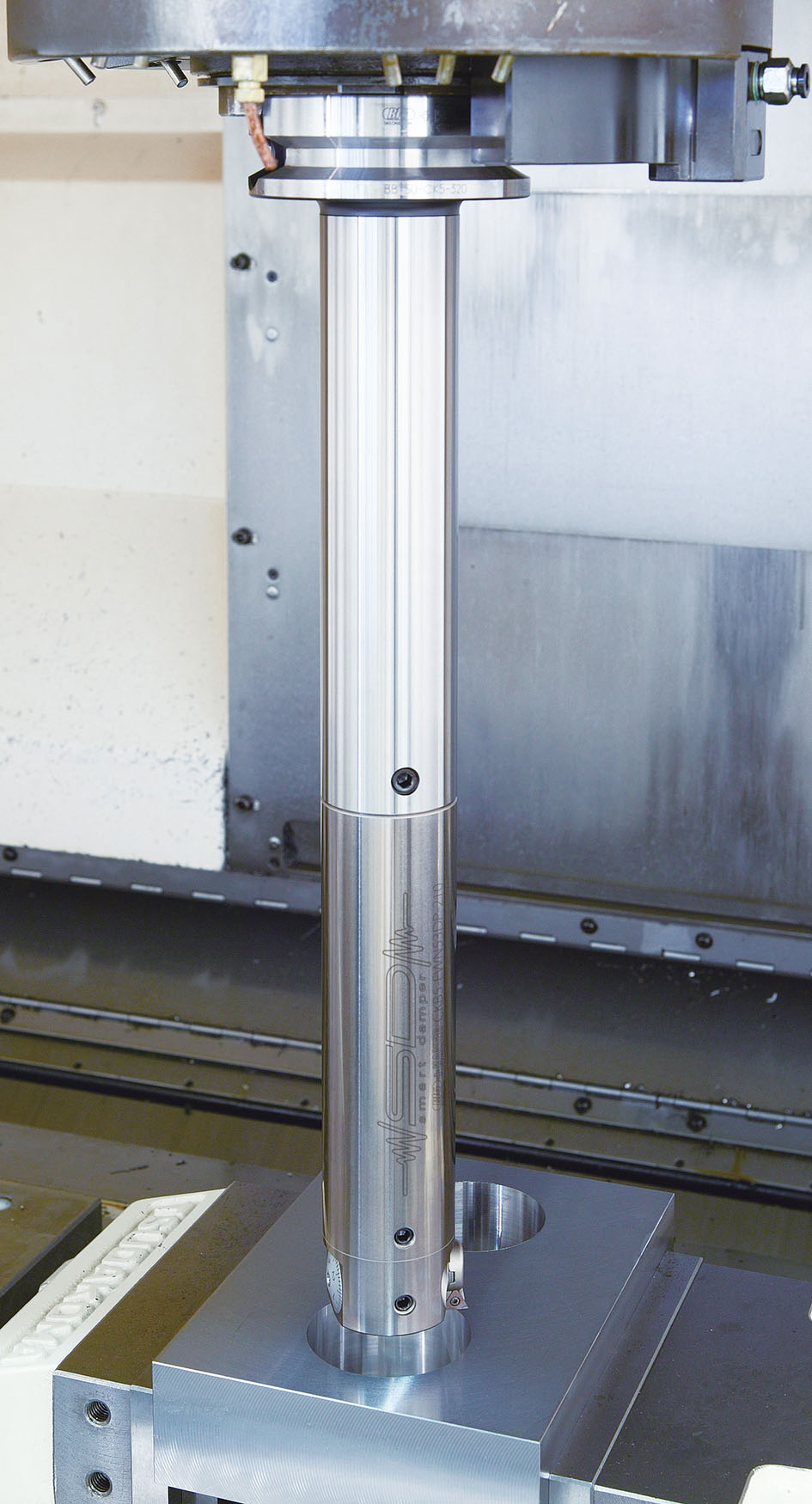

The ability to improve productivity and performance is derived from the introduction of BIG KAISER’s Smart Damper technology that will reduce chatter and subsequently cycle times, delivering exceptional machining accuracy and surface finish quality. The EWN Monoblock fine boring heads have been expanded with the new CK1 and CK2 products that support the machining of diameters from 20 to 36mm and 25 to 47mm respectively. The full EWN monoblock family of products ranges from the smallest CK1 to the largest CK7 which now supports fine boring from 20mm to over 200mm diameter.

The innovative Smart Damper mechanism that has been introduced to the EWN Monoblock CK1 and CK2 products helps to absorb vibration, essentially eliminating chatter and thereby achieving higher levels of precision with superior surface finishes. Thanks to its inherently stiffer design, the Monoblock boring head ensures high precision even when machining long bores.

The EWN Monoblock CK1 and CK2 heads do not have an interface and this enables significantly tighter tolerances to be achieved. A major advantage of the BIG KAISER’s Smart Damper technology from ITC is that it eliminates the need to reduce cutting speeds to manage vibration. This categorically increases metal removal rates and subsequently raises productivity levels.

Giampaolo Roccatello, Chief Sales & Marketing Officer for Europe at BIG KAISER, explains: “These new boring heads are ideal for achieving deep, chatter-free boring in challenging materials. Together with our EWB and EWB-UP ranges, the EWN boring heads represent some of the most advanced and sophisticated tools available on the market.”

Leave a Reply