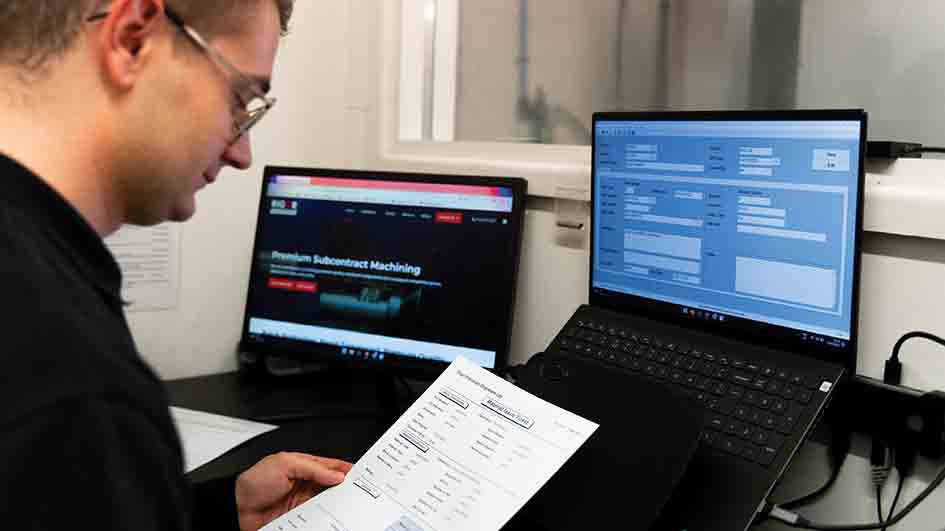

Joe Jordan, Director of Rigor Precision Engineers Ltd in Newmarket, says that the company’s investment in PSL Datatrack production control software has significantly helped in the development of the business.

There has been a major increase in the number of new and repeat customers, for batch manufacturing of precision CNC machined components, as a direct result of faster and more streamlined production administration. Utilisation of the company’s CNC turning and milling machines has been much improved and the investment has also had a positive impact on its product design and prototyping services.

Rigor has traditionally catered for customers in many different industries (including science and technology) looking for high efficiency subcontract batch production services, specialist product design and review services as well as rapid turnaround, high-quality prototype components. The company’s philosophy is based around a “can-do” attitude when it comes to servicing both new and existing customers. “If we can machine and produce a component then we will,” says Joe.

One of the difficulties with this approach, however, was that Joe and his colleagues were having to spend an excessive amount of time in the office undertaking the associated production administration as the business grew. For quotations, Joe had been using an Excel spreadsheet but the information recorded was not easily accessed and did not link to any of the company’s data regarding material suppliers, stock levels or pricing.

Consequently, too much time was taken with tasks such as finding out what materials were going to be required (even for repeat jobs), raising purchase orders and obtaining new prices for subcontract processes such as plating that had been used in the past. “It was all getting in the way of running our business efficiently, when we could have been spending time programming and running the machine tools,” comments Joe.

Having been aware of PSL Datatrack for some time, Rigor had also been recommended the software by other subcontract precision engineering businesses. With orders increasing significantly and administration requirements escalating, PSL Datatrack were contacted and an online demonstration of the software arranged.

Rigor were shown how all necessary production data could flow from quotation to final invoice, all within one purpose-designed production control system. A number of modules were subsequently acquired which would give Rigor a means of integrating quotations, materials, supplier information, costs, works orders, delivery details and invoicing data.

Also included in the initial package were a number of web-based training sessions, all completed prior to going live. The existing Excel spreadsheet system and the new PSL Datatrack software were run in tandem for a short period and all of Rigor’s historic customer records, including quotations and orders, were migrated.

One of the major improvements has been the generation of quotations. There is no longer any need to go back to suppliers or recalculate material costs, as all details are readily available in the Material Stocks module with prices logged against each item. The software also records and monitors subcontract costs. “With everything in one place, the biggest advantage is our fast turnaround on quotes with great accuracy. We have become more competitive and are winning more business as a result,” continues Joe.

All of Rigor’s other administration has also been massively streamlined, particularly for repeat jobs, as everything related to that order is stored in PSL Datatrack and easily accessed. The system will autofill any necessary information, such as material and subcontract details in the Purchase Orders module, to prevent manual data re-entry.

Rigor has therefore been able to change its business model and move towards more batch production work, confident in its ability not only to produce high-quality components on time but also to handle all the associated administration – an inevitable result of acquiring new customers with varying production requirements. Time is no longer wasted awaiting the arrival of materials to complete jobs – they are now queued and ready for completion on the shop floor, boosting productivity.

“I’d never had any previous experience with production control software but after minimal training I was up and running with PSL Datatrack in no time. With their support it has been easy to follow and understand. All the information we require to run the business is readily available, saving us no end of time and making us more responsive to our customers’ needs,” concludes Joe.

For more information, visit www.psldatatrack.com or contact PSL Datatrack, Lily Hill House, Lily Hill Road, Bracknell, Berkshire, RG12 2SJ, Tel: +44 (0) 1344 827312, Email: sales@psldatatrack.com

-ends-