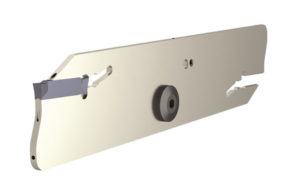

Gühring has now expanded its grooving and parting-off to include a new grade with a blade width of 3mm for parting-off stainless steel materials. The System 222 expansion adds to the existing indexable inserts for steel materials. With two cutting edges and a length of 22mm, the new indexable insert is ideally suited for parting off the most common bar diameters.

The enhanced series also offers an extensive range of clamping holders with and without an internal coolant facility. As many production facilities use a mixture of steel and stainless steel materials, there has been an increase in the demand for stainless steel in particular. This has been created by elevated demand in the medical technology, automotive and general mechanical engineering sectors where machinists continually encounter stainless and other difficult-to-machine materials.

With this rise in demand and following the successful launch of the 3mm indexable insert for steel machining, Gühring has now developed an insert for stainless steel machining. In series production, this new indexable insert is perfect for parting-off operations on turning centres with a barfeed system. As parting-off is frequently the last application in a machining cycle, process reliability during parting-off is critical. If the tool breaks, the finished component could be damaged at the point where it is at its most valuable after significant machining time. This is why it is important to use an insert with geometry, material composition and coating that have all been specially optimised for this application.

The experts at Gühring placed a major emphasis upon the interplay between chip breaker, carbide grade, coating and the design of the cutting edge – the results are astounding. During the development of the new stainless steel insert, Gühring experts advanced the chip-breaking technology considerably. The result is an insert with an extremely effective chip breaker. After all, “Process reliability equals chip breaking and chip breaking equals process reliability,” explains Marco Bücheler, Product Manager for Grooving Tools at Gühring.

With grooving and parting-off, a chip breaker has to work hard. It constricts the chip movement as the chip has to be narrower than the groove width and it makes the chip roll up to a compact formation and finally, it breaks the chip. When all three elements are achieved, the result is reliable chip removal and a high surface finish quality.

For safe and effective swarf removal, a targeted coolant supply is also recommended. This reduces temperatures during machining and minimises insert wear whilst underpinning the aim of improving surface finishes. The System 222 toolholders have a through coolant system for direct fluid supply to the cutting surface. To simplify ease of use for operators and reduce set-ups, the connection for the internal cooling is tubeless. The perfect combination of the insert geometry, material composition and coating is the result of considerable testing by the experts at Gühring. A pre-series of tools were then produced and tested in the field by Gühring customers.

The customer feedback was consistently positive with a performance level far exceeding that of competitors’ tools.

In just one example, the feed rate was increased from 0.06 to 0.08mm, which resulted in an impressive reduction in machining time with the same cutting speed. With a series run of 15,000 components, this customer made a time saving of more than five hours. Despite the higher feed rate, the Gühring created 40% more parts per insert edge with a 25% productivity gain. Marco Bücheler’s conclusion: “We have a technically flawless product. Our field tests have shown that we perform well and are competitive with this insert in a wide range of stainless steel materials.”

Email: info@guhring.co.uk

Web: www.guhring.co.uk