The Liechti Turbomill 1400 g offers a solution for roughing and finishing blades up to 1.4 metres long.

Critical aerospace engine turbine fan blades and high-bypass turbines produce much of an aircraft’s forward thrust.

In the past, precision-forged blades needed only light finishing operations to achieve the tolerances required.

Today, with the growing demand for greater fuel efficiency tighter tolerances are required, and many manufacturers have responded by machining oversize forgings to final net shape.

Typically machined from titanium alloys, newer blade materials include aluminium and carbon-fibre composites. Carbon-fibre blades attach titanium leading edges to the relatively brittle composite material – a design element that minimises damage should an engine ingest foreign objects.

Titanium aluminide used in blades in the low-pressure sections of some new engines is very brittle but provides high heat resistance.

Futuristic materials and the complex shapes required to securely unite them into a single turbine blade need equally futuristic machining processes – particularly when it comes to machine movement.

Changing direction quickly is as important in machining as it is in motorsport. On a straight track, acceleration and deceleration are relatively simple, but when the track turns, the car must decelerate to negotiate the corner and accelerate back to top speed again. The winning car must decelerate into the curve, track the turn accurately, and accelerate back out more quickly than the competition.

When machining the edges of a turbine blade, 5-axis movement is much more demanding than driving on a race circuit, but the principles are the same. Machines must move cutting tools around the blade edges at speeds that can produce as much as 1g of acceleration and deceleration force to maximise productivity.

To meet the standards of aerospace manufacturers, the machine must also be able to produce a high-quality, finished blade that requires minimal polishing and less bench work than a blade processed on a general-application machine.

High g resistance

GF Machining Solutions’ Liechti Turbomill 1400 g airfoil machining platform can handle these challenges.

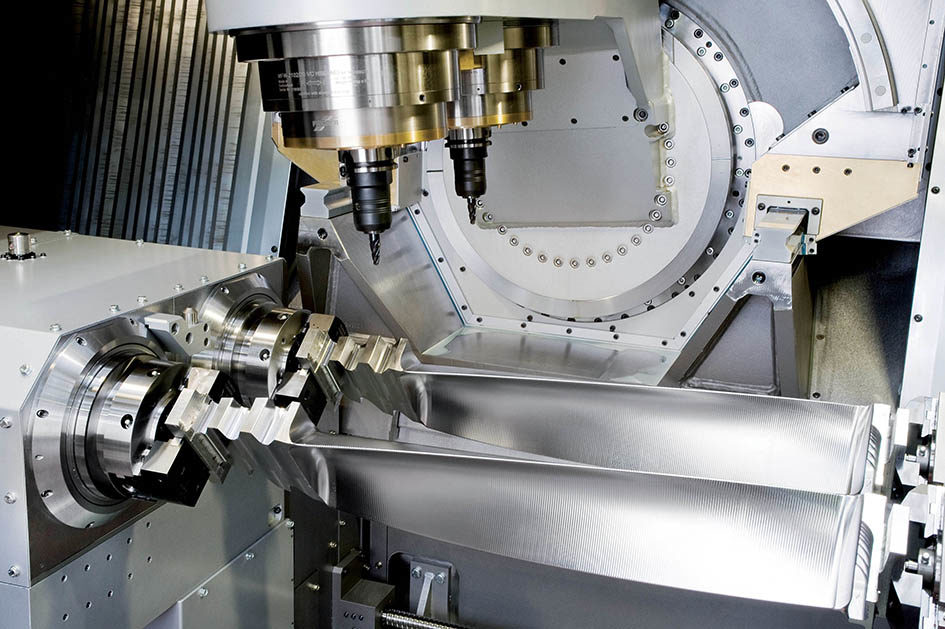

The Leichti Turbomill 1400 g is an advanced turbine blade machine designed for fast, cost-efficient production of medium-to-large blades for jet engines and power generation. The machine’s configuration means that blades are clamped at each end of the machine and rotated between centres whilst a milling tool performs cutting operations

The motion creates complex airfoil contours, allowing the machine to perform heavy-duty roughing and dynamic finishing for the airfoil, root form, and shroud.

The machine rapidly creates complex profiles on the leading and trailing edges of the blades that control airflow into the engine while maintaining the tight tolerances that maximise fuel efficiency.

(Some machine tools can start and stop simple straight-line machine movements at 2g. The Turbomill 1400 g performs accurate three-dimensional machining at 1g).

Acceleration and deceleration at 1g generate significant force – strong enough to topple the machine over if it is not securely anchored to the floor. The Liechti Turbomill 1400 g uses its large size, weight, and rigidity to resist these forces. Machine ways are engineered with the strength to handle extreme momentum and inertia. The X-axis moves via a linear drive, the Y- and Z-axis on ball screws, and direct-drive motors power the rotary B- and A- axes, which is key to moving tools quickly around a blade’s leading and trailing edges.

The Liechti Turbomill 1400 g is aimed at OEMs and large Tier 1 manufacturers involved in high-volume turbine blade production – and is able to machine blades twice as fast as conventional and multi-purpose machines.