Valves include sealing seats with the sealing bodies usually being balls. Examples can be found in general pneumatics, hydraulics or also in injection systems of combustion engines. The sealing seats only become perfectly tight as a result of the finishing. The first choice here are lapping pins, such as those made by Elgan Diamantwerkzeuge GmbH in Nürtingen.

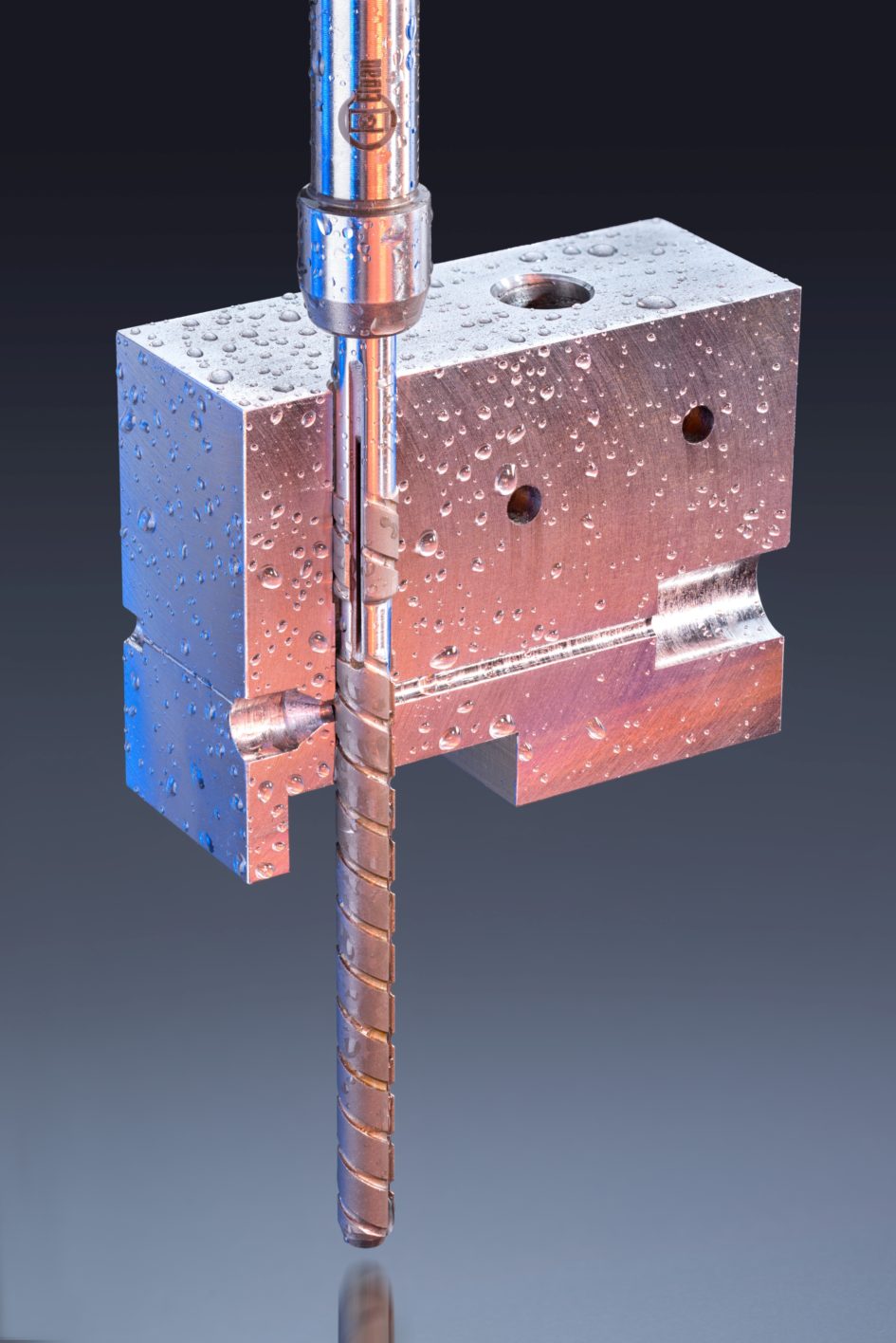

Modern diesel engines often inject fuel into the combustion chamber several times during an ignition process. This quick succession requires components with maximum reliability and this is particularly true of injection pumps. The valves here have a 120-degree sealing seat for one ball. The seat diameter is just 1.8 mm. The function requires one-hundred percent sealing, i.e. the ball must have exact continuous line contact to the seat. The form and surface quality of the seal bevel cannot be high enough. Normal counter-sinking or boring tools are far from suitable for such finishing. Only lapping pins with diamond coating achieve the desired qualities. The process is not intrinsically complicated. The lapping pins are held on the valve seat at a specific speed and defined pressure for just a few moments. Cooling lubricants prevent the temperature rising and support the removal of material. Depending on requirements, one, two or more finishing levels with different diamond grits may be required.

High number of pieces between resharpenings

Easy to use, but difficult to manufacture. It is not evident at first sight, but the lapping pins contain a great deal of expertise. An important criterion – in view of the short cycle times – is the high number of pieces between resharpenings; these can only be realised with the assistance of special techniques. Qualified experts determine the best functioning grits and grit qualities in the laboratory. The diamond cutting part then has to be reliably connected to the steel tool body. Simple pins, for which no regrind is intended, have a single-coat diamond layer. Things become more complex where demands are greater and the diamond part has a several-layer connection with the metal base. Under certain circumstances, small diameters require mechanical pre-machining of the metal pins to make the adhesion surface as large as possible. Such details and the coating itself are what demand real skill. “We provide regrindable lapping pins with a diamond cutting part with diameters from 1.4 mm, which makes us a market leader,” explains Michael Nagel, Sales Director at Elgan Diamantwerkzeuge GmbH & Co. KG in Nürtingen.

Nagel recalled how the development of lapping pins for injection pumps began about ten years ago, “The number of pieces between resharpenings has been increasing continuously over time. At the outset of the project, the customer requested 100 pieces before the first resharpening. We managed 250 at first go. The customer raised their request to 800 parts in the next step. We then achieved 1000 parts. Today, it’s much more.”

Key processing in valve technology

Another example: pneumatic and hydraulic components for all kinds of tasks in vehicle construction, aerospace or medical technology. Conventional chip removal and grinding tools are only possible for the pre-machining of the ball and conical sealing seats. Users emphasised that the required circularities and surface qualities could not be achieved in this way. In a further step, a stamping die admittedly improves the quality of the seats noticeably, but still not enough. The rest is up to the lapping pins of the Nürtingen diamond specialists. Apart from lapping pins, there is no other known procedure suitable for the finishing.

Diamond tools for many tasks

Diamond-coated tools are frequently used during refined abrading. Diamond allows high material removal and excellent long-term stability or high numbers of pieces between resharpenings. Elgan Diamantwerkzeuge GmbH & Co. KG in Nürtingen is specialised in producing such tools. Elgan is a company in the Nagel Group, which also produces honing and super-finishing machines. Consequently, honing and super-finishing tools make up the greater part of the tools developed by Elgan. But the product line extends even further, including deburring, grinding, lapping, polishing and dressing tools, as well as diamond coatings for dogs or grabs. “Our options for working diamonds are practically unlimited,” according to the Development Manager Josef Schmid. “We have all the technologies needed in-house as well as high-tech testing methods, such as electron microscopy or grit size analysis using laser diffraction and the latest methods for form and surface analysis. This means we can produce diamond coatings for every conceivable application.”

In general, the focus is on individual special solutions for the highest demands. “Customer requirements are becoming increasingly specialised, above all due to the development of new materials and coatings, but also due to different philosophies with regard to surfaces and load scenarios. Therefore, there are hardly any more standard solutions to further boost efficiency and performance in the drive technology even more. By keeping pace with this development with constant new solutions, we not only reinforce our own competitiveness, but above all that of our customers,” summed up Josef Schmid. More information: www.elgan.de