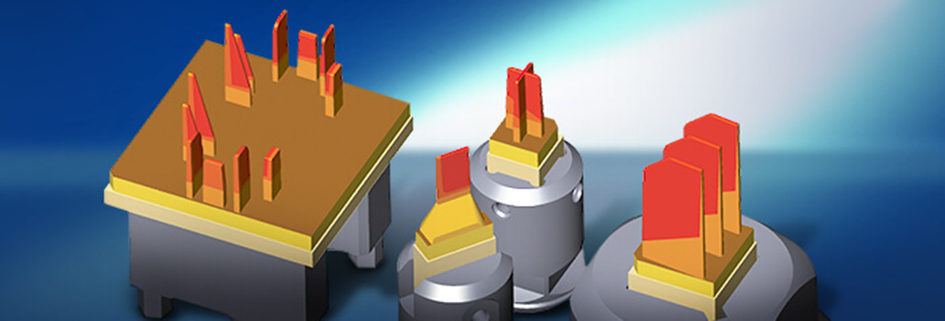

CAM manufacturer OPEN MIND Technologies has now introduced its new hyperCAD®-S Electrode, an innovative module for automating the design and production of electrodes for die-sinking.

hyperCAD®-S is an integrated CAD software for hyperMILL® users that is specifically tailored to the requirements of CAM programmers. The most notable addition to Version 2017.2 is a module that enables the quick design of die-sinking electrodes. Thanks to the module’s convenient and automated process, users can simply base their electrodes on the face to be die-sunk within the component geometry – no specialist expertise is required.

The starting point is given by the faces to be die-sunk within the component geometry. The NC programmer selects these and the CAD software automatically extends the electrode faces as needed as well as selecting the blank and holder from a library. The module is suitable for both solid and face models and the geometry can be selected via faces as well as contours. Any holes in the geometry are filled automatically, and hyperCAD®-S also calculates the minimal rib distance, the blank’s excess and the C angle offset. All the technology data, such as spark gap, blank size, positional reference and coloured areas are automatically transferred to hyperMILL®.

The electrodes designed in hyperCAD®-S are then directly transferred to the CAM system for further processing. The user simply selects the electrode in question and commences programming. A separate dialog window is available for this, where the milling job for the electrode is specified. Once all the details are entered, hyperMILL® automatically generates a job list containing all the relevant parameters.

For more information:

E: adrian.smith@openmind-tech.com

www.openmind-tech.com