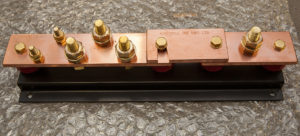

As a leading manufacturer and distributor of earthing materials and lightning protection equipment, Kingsmill Industries products are used across a wide range of construction projects, mainly new builds, including churches, apartment blocks, offices and factories providing protection from lightning strikes. The Pinxton, Derbyshire-based business is seeing a significant growth driven by the booming construction sector in the middle east and, with the majority of its products manufactured in-house it needed to increase production and productivity and turned to XYZ for help.

An Earth Bar machined on the XYZ SMX 2500 bed mill

Turning was a priority as a replacement was needed for an ageing CNC lathe and the XYZ Compact Turn 52 with an optional LNS barfeed was the perfect solution. The Compact Turn 52 provides excellent capacity from such a small footprint machine (1700 x 1450 mm, excluding barfeed), with its 52 mm bar capacity, 20 hp/5000 revs/min spindle and control being provided by the easy to use Siemens 828D ShopTurn Control. The gains that Kingsmill Industries were looking for were immediately apparent with cycle times being cut by 50 per cent compared to the machine it replaced.

“We have a wide range of components that make up our products and batch sizes can be quite large, so the barfeed fitted to the XYZ lathe is perfect. We are confident that we can leave the machine running for extended periods unmanned, with just the occasional intervention to check tolerances and empty the swarf bin,” says Ashley Jones, Kingsmill Industries Production Manager. “We find the Siemens control extremely user-friendly and the combination of control, machine, barfeed means that the XYZ CT52 gives us what we needed at a price that we were happy to pay.”

The multi-part tip of a lightning conductor machined on the XYZ Compact Turn 52

he XYZ Compact Turn 52 has cut cycle times by 50 per cent at Kingsmill Industries

The XYZ Compact Turn is the second XYZ machine at Kingsmill Industries as it also purchased an SMX 2500 bed mill to help manage its milling requirements. Fitted with the ProtoTRAK SMX control system this mill is used for general toolroom and low volume second op-type work for which the machine and control are ideally suited. As with the Siemens control Ashley Jones cites the ProtoTRAK’s ease of use as a major influence on the decision to purchase the SMX 2500. One area of use is in the manufacture of Earth Bars. “Our earth bars can be tailored to meet specific requirements, which means lots of variants in relatively low volumes. So the ease of which we can program and set up the SMX 2500 is a major benefit.”