A gear will be power skived on an Okuma Multus U4000 2SW multi-tasking turn-mill centre

The Genos M460V-5AX vertical machining centre

The Okuma Spaceturn LB3000 EX II turn-milling centre will make its first appearance in the UK equipped with the Japanese manufacturer’s Armroid robotic arm, the first in the world to be integrated inside a CNC machine tool. It will be configured for automated handling of shaft-type parts. All Okuma machines are sold and serviced exclusively in the UK and Ireland by NCMT (www.ncmt.co.uk), stand 120 in Hall 19 at MACH 2020.

Three different end-of-arm effector options are available for the robot, capable of performing different tasks. One is for blasting the cutting zone with air to improve chip management. Another provides additional support during the cutting process to prevent chatter. In combination with a workpiece stacker, the third effector automatically loads and unloads workpieces weighing up to 5 kg. All three are stored within the machine and are changed automatically by the robot.

While most conventional robotic systems require complex integration and special training for staff, Armroid needs neither. As the robot is part of the machine tool, separate system integration is unnecessary. Using Okuma’s own OSP-P300A control, an operator enters the coordinates for the start and finish points and the robot moves through its motions, the cycle being automatically generated to avoid collisions. In addition to automated running under program control, manual operation is possible via a pulse handle that micro-positions the arm.

A longer and more powerful robotic arm, Armroid Type 2, will be integrated into an Okuma Multus B250II multi-tasking lathe for high mix, small batch billet work. It is capable of handling workpieces up to 10 kg and possesses a fourth end effector with a 3-jaw workpiece hand.

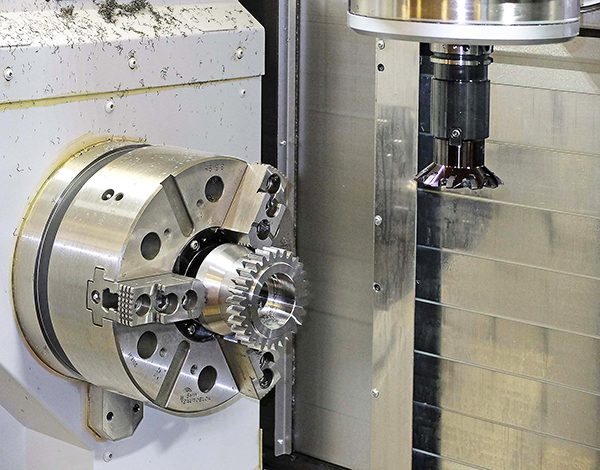

There will be a second Multus machine on show, a U4000 2SW with an opposed spindle. It will be set up to demonstrate the ease, efficiency and cost-effectiveness of power skiving for the production of external and internal gears and splines to world-leading accuracy on a generic 5-axis multi-tasking platform. It is made possible by the robust machine construction and high levels of accuracy and repeatability combined with leading-edge software.

The process is intended for producing gears from solid billets in large volumes using a dedicated skiving tool to sequentially rough and finish each type and size of gear. Even with deep tooth profiles, a Class 6 spur gear can be achieved due to accurate synchronisation of tool and workpiece rotations. Other gear production techniques are also possible, including hobbing, shaping and spiral bevel milling.

The final turning machine on the stand will be a Genos L2000 with a gantry-type workpiece load / unload system. Production of a flange-type component will be demonstrated.

Machining centres – Okuma

NEW HORIZONTAL MACHINING CENTRE IS HIGHLY PRODUCTIVE AND COMPACT (NEW)

The MB-5000H Series 2 twin pallet, high speed, horizontal-spindle machining centre from Okuma will make its first UK appearance at MACH 2020 on stand 120 in Hall 19. Production of an aluminium engine casing on one pallet and machining of a solid steel block on the other will demonstrate the very high output achievable with this production centre.

The thermally stable machine offers greater rigidity, higher acceleration, shorter tool change and table indexing times and higher power compared with the previous Series 1 model. Powerful cutting capabilities and high speed automation reduce cycle times and increase productivity by up to 25 per cent, while the 20 per cent smaller footprint maximises utilisation of valuable shop floor space.

The 15,000 rpm, 26 kW, direct drive, internally cooled spindle is fed with cutters from a 48-position disc-type tool magazine. Integrated cutter breakage detection allows for autonomously managed sister tool replacement. Static turning tools can also be exchanged to enable turning and profiling of bores and ODs using special turn-cutting software in the Okuma control that synchronises circular interpolation of the X and Y axes with spindle feed motion in Z.

With travels of 760 mm in the X, Y and Z axes, rapid traverse at 60 m/min and a highly dynamic, roller cam gear-driven B axis with 0.001 degree resolution, the MB-5000H enables efficient machining of the most complex parts, assisted by flood coolant to optimise chip management. In-process quality control can be integrated using a Renishaw RMP600 probe to inspect dimensions and feed the necessary offsets back to the control.

The Genos M460V-5AX vertical machining centre with a working volume of 762 mm x 460 mm x 460 mm, launched at the last MACH show, will be in evidence again producing a spiral bevel gear. It was the first 5-axis machine in Okuma’s popular Genos entry-level range but has since been joined by the larger M560V-5AX with 1,050 mm x 560 mm x 460 mm travels. Both machines are designed to manufacture high precision parts at impressive metal removal rates in a compact footprint.

The trunnion with rotary table and 5-axis simultaneous control give the machine the ability to cut even the most complex of components in a variety of materials, from titanium to aluminium, and it does so without sacrificing dimensional accuracy, finish quality or productivity. The BT40 spindle is rated at 15,000 rpm / 22 kW. A 32-position tool magazine is provided and control is by the proprietary, user-friendly OSP-P300M CNC.

Highly rigid, thermally-stable, double column construction protects the vertical machining centre structure from deformation, resulting in high machining performance. Okuma’s Thermo-Friendly Concept is nevertheless included in the specification, applied to both the machine structure (TAS-C) and the spindle (TAS-S), based on feedback from temperature sensors to deliver high accuracy machining in a normal shop floor environment. Tests have shown thermal deviation to be less than 10 microns over a 24-hour period, despite a variation in ambient temperature of as much as 8 degrees Celsius.

Features such as Okuma’s 5-axis tuning system that accurately fine-tunes the geometry of the machine for ultra-high precision and Okuma’s Absoscale linear encoders on the X, Y and Z axes are all part of the standard package. So also are ServoNavi AI and ServoNavi SF, which automatically detect workpiece weight and adjust the machine’s feed drives to achieve higher speed production of lighter components.

Machining Navi, an optional feature that minimises chatter by finding the best cutting conditions, employs a microphone to detect the onset of vibration and feed information back to the control. A change in spindle speed is then recommended to suppress the chatter.

Industry 4.0 – Okuma

The theme of NCMT’s Okuma stand at MACH (the agent has a second stand focusing on Makino products) will feature Okuma Smart Factory, as did the principal’s stand at EMO 2019. It will exemplify how Industry 4.0 applications can improve manufacturing processes by linking every machine tool throughout an entire manufacturing environment to Connect Plan. The solution allows complete visualisation of the factory and provides analytics for improved machine tool utilisation.

Connect Plan achieves traceability by tying together the individual ID of a machined workpiece with the cutting data and gauging results for each production centre. It eliminates sources of errors, improving manufacturing quality as well as reliability. In addition, by collecting process data, maintenance intervals can be accurately predicted and scheduled. Connect Plan even integrates machines from third-party providers. Real-time data including the operational status of the machines is accessible on PCs and mobile devices from any location.

Okuma has collaborated with other machine tool builders, software companies and control manufacturers to create a universal machine tool interface, umati, which enables machines and peripherals to connect to customer-specific IT ecosystems. umati has been developed on the initiative of VDW (German Machine Tool Builders’ Association) and is based on the international interoperability standard OPC UA, making the integration of new machine tools into existing IT environments easy, secure and seamless.

umati is becoming an open standard for machine tool users worldwide. Okuma customers will be able to connect their machine tools without any modification, as the machine builder has developed a umati interface for its proprietary OSP Windows-based open architecture control.

Higher levels of automation and more complex manufacturing make it increasingly difficult to predict and avoid errors. Okuma’s 3D Virtual Monitor is advanced software that provides an accurate, three-dimensional simulation of the entire manufacturing process. To ensure high accuracy, the solution relies on the exact specification of the Okuma production platform to be resident within the CNC system. With end-to-end simulation of the machining process and transfer operations, programming errors can be detected before actual machining starts, avoiding costly collisions and increasing safety.