Founded on October 15th, 1964, by Günter Blase, igus® has been keeping the world moving with its lubrication-free high-performance plastics ever since. Blase had to take a risk to win over the first prospective customer for igus®; Pierburg. Their enquiry was for a complicated carburettor component, few companies at the time would have thought of using plastic as a solution and fewer still would have had the idea to injection-mould it. As the first perfect plastic valve plug dropped from the injection moulding machine, it was clear that igus® was set to become a big name in the industry. Now a leading motion plastics manufacturer, their products can be found everywhere in cars, cranes, furniture, machine tools and robots – even in bicycles. When it comes to moving components, igus® believes it is time to ‘ GO ZERO’ with lubrication, evidenced by the extensive product range of high-performance plastics.

The igus:bike marks the beginning of a new chapter in sustainable mobility, made using recycled ocean plastic waste. The ultimate goal with the igus:bike is to establish local production near waste plants worldwide and therefore close the plastic recycling loop. After three and a half years of development, the dream of an urban bike made from plastic waste became a reality. Initially produced using 50% recycled ocean plastic from discarded fishing nets, the igus:bike is the world’s first bicycle made using recycled plastic. “The igus:bike is a permanent development project. When you see an igus:bike on the road, you know that something completely new is being explored and with that comes constant changes and improvements.” says the managing director of igus® in the UK, Matthew Aldridge.

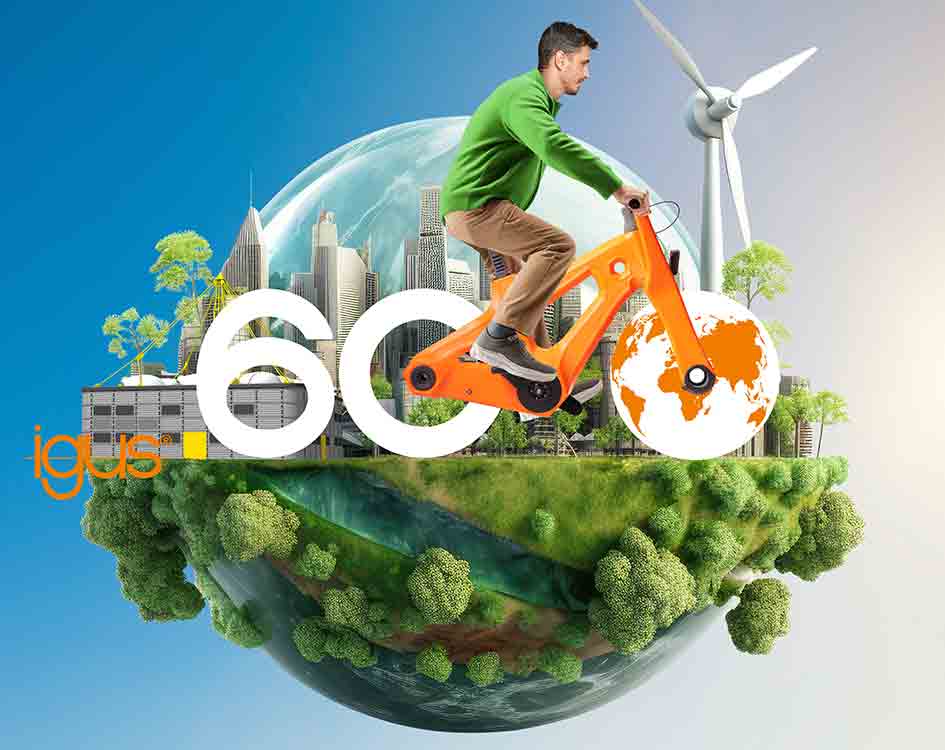

From fishing nets to bicycles

In the future, igus® plans to make the bike available all over the world. Even in countries where there is a lot of waste, igus® wants to set up local production lines for the bike. As well as helping with plastic waste recycling, this will also create jobs.

“As a company that has been manufacturing industrial components from plastic for 60 years now, we are committed to driving the transformation to a sustainable circular economy of plastics. The igus:bike is a significant milestone on this path,” says Aldridge. “As the bike travels with us through the UK, we hope to inspire many companies and customers to get involved.”

Plastic waste from landfills all over the world could become the raw material for the igus:bike in the future. igus® manufactures the individual components using rotational and injection moulding – from the frame to the bearings and drive crank. Since the start of development, the material researchers have succeeded in gradually increasing the percentage of recycled plastic– and the trend is rising. This makes it possible to process discarded fishing nets, shampoo bottles and other plastic waste into recycled pellets for rotomoulding machines, turning these into a valuable resource.

The green light was given for the igus:bike to begin the world tour and it has set off from the igus® factory in Cologne, Germany. October marked the 60th birthday of igus® and to celebrate the occasion, the bike will travel the world for a whole year. The urban bike highlights the many advantages of igus® “motion plastics” products, endeavouring to bring industry partners, media representatives and consumers closer while showing how the transformation to a sustainable circular economy of plastics can succeed. This bike does not rust, does not need oil and is almost entirely maintenance-free. Components such as ball bearings, crank and freewheel do not require any lubrication at all, as they are made of igus® high-performance plastics.

Over the next year, the plastic bicycle will be travelling across at least 16 countries – including Germany, Italy, China and of course here in the UK. The aim is to show industrial customers, recycling partners, the press and consumers that plastics do not have to end up in incineration or landfill and instead can help shape the transport of tomorrow. As it travels to each igus® subsidiary, the bike will visit various customer factories. Once it reaches the UK, expected to be summer 2025, the bike is set to travel across the country, sightseeing and highlighting customer applications along the way. With this worldwide tour, igus® hopes to make customer stories come alive at every stage.

Smooth cycling and easy maintenance combined

Not only is this recycled plastic bike practical, but it is also an exciting step forward for sustainable travel that is fun to ride and easy to use, being weather-resistant and corrosion-free. The high-performance plastics also enable low-friction dry running without any additional lubricants, which often become a dirt magnet in other bicycles. The bicycle demonstrates the many advantages of igus® motion plastics, which can be experienced by everyone as part of the world tour.

Follow the tour of the bike live via https://blog.igus.co.uk/