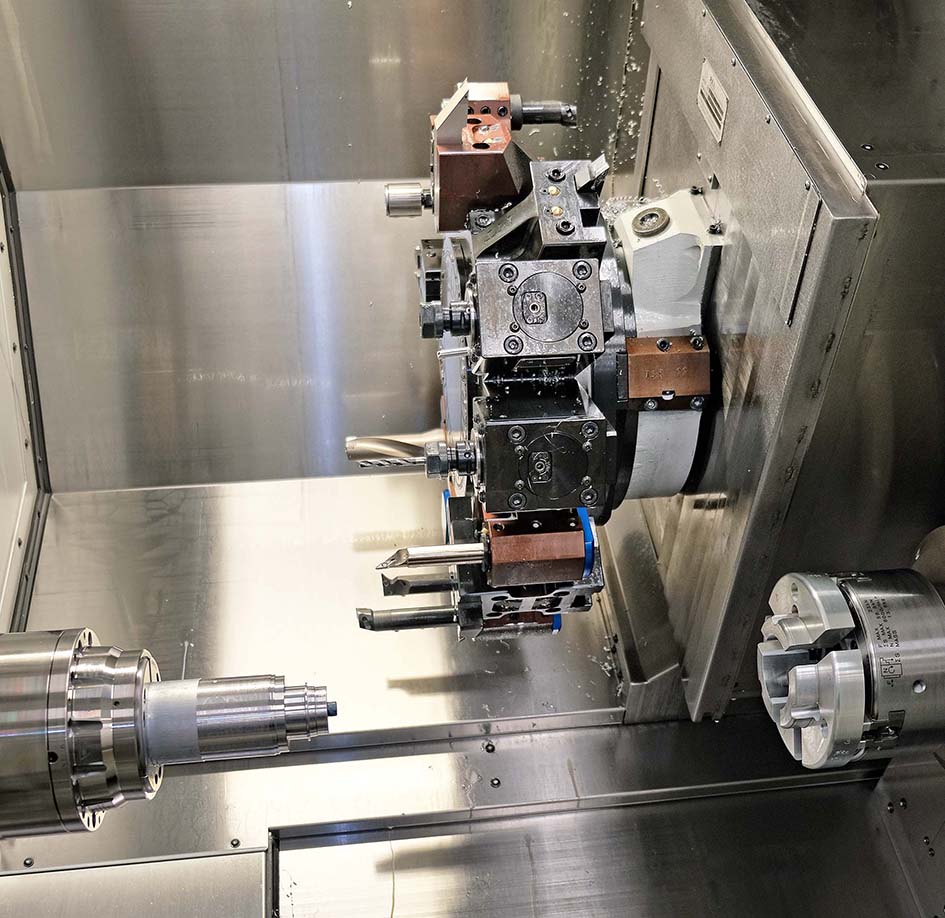

Vision Engineering (www.visioneng.com), states they are the world leader in ergonomic microscopy, digital 3D visualisation and metrology solutions, has bought a third fixed-head lathe, an Italian-built Biglia B620YS, for its production facility in Send, near Woking, Surrey. Supplied by UK and Ireland sales agent Whitehouse Machine Tools (www.wmtcnc.com), the machine was installed to turn a range of aluminium components for the top-quality objectives in Vision Engineering’s third generation of Mantis eyepiece-less 3D inspection microscopes, launched at the beginning of June 2023.

The choice of this turning centre was based on a set of specific requirements. There is no milling content in any of the cycles, so only turning tools are required and a single tool turret was therefore sufficient. Excellent turned surface finish is essential so that no marks are visible after the parts have been anodised, as a good cosmetic appearance is important for customer acceptance.

Dimensional accuracy is also key to ensure perfect perpendicularity for precise lens placement and to facilitate clean-room assembly, bearing in mind that anodising deposits a layer of variable thickness that uses up some of the drawing tolerance. Additionally, lathe delivery was needed in a short time frame to enable Vision Engineering to ship Mantis 3rd Gen stereo microscopes to its worldwide distributors in time for the launch, as well as to maintain production momentum in the immediate aftermath.

Machine shop manager Scott Blackwell said, “The Biglia lathe was available ex-stock from the Whitehouse showroom in Kenilworth. This was an advantage due to the large production volumes that needed to be achieved across the range of aluminium objectives for our latest microscopes, which meant that extra turning capacity was needed quickly.

“Our other two fixed-head lathes, both twin-turret models, were from a Japanese manufacturer so it would have made sense to return to the same supplier for consistency of programming and operation. However, the Biglia installation has turned out well. The lathe is a real workhorse, the turned parts it produces are impeccable and the unmanned running has proved to be very consistent.”

He explained that better than the +0, -50 microns typical drawing tolerance is held without manual intervention and inspection shows that midway in the tolerance band is routinely achieved. Bearing in mind that there are many hours of lights-out production every week and cycle times are relatively short (from 10 minutes for an objective body down to three minutes for a spacer), if the bar-fed lathe were not reliable, a lot of scrap could be produced during unattended running.

The B620YS was supplied as a turnkey installation by Whitehouse Machine Tools, including preparation of some programs and unlimited training. Provided as part of the package was support, together with Mastercam, in developing a post processor to translate toolpath information from Vision Engineering’s CADCAM system, a Multifeed 80 bar magazine from Hydrafeed, Sandvik Capto C3 tooling, Tungaloy standard tooling and a JNS parts catcher that was modified to increase its depth so that it can accommodate all of the many components produced during lights-out operation. Parts handling was an important consideration for this application due to the high level of cosmetic appearance required.

Between the beginning of February and the end of May 2023, 11,000 objective components were produced in readiness for the Mantis 3rd Gen launch. Annually, 21,500 parts are expected to be turned to satisfy predicted global sales across the range of instruments, so there is considerable spare capacity on the Biglia for further machining.

The turning centre will therefore be deployed on production tasks for different objectives in other inspection equipment manufactured by Vision Engineering, as well as on R&D work for a sister company in the subcontracting sector, Hinckley-based Milturn Precision Engineers. That will entail turning thin-wall components to tighter tolerances, down to 10 microns total, and will also involve the use of driven tooling in the 15-station Y-axis turret.

www.wmtcnc.com

Leave a Reply