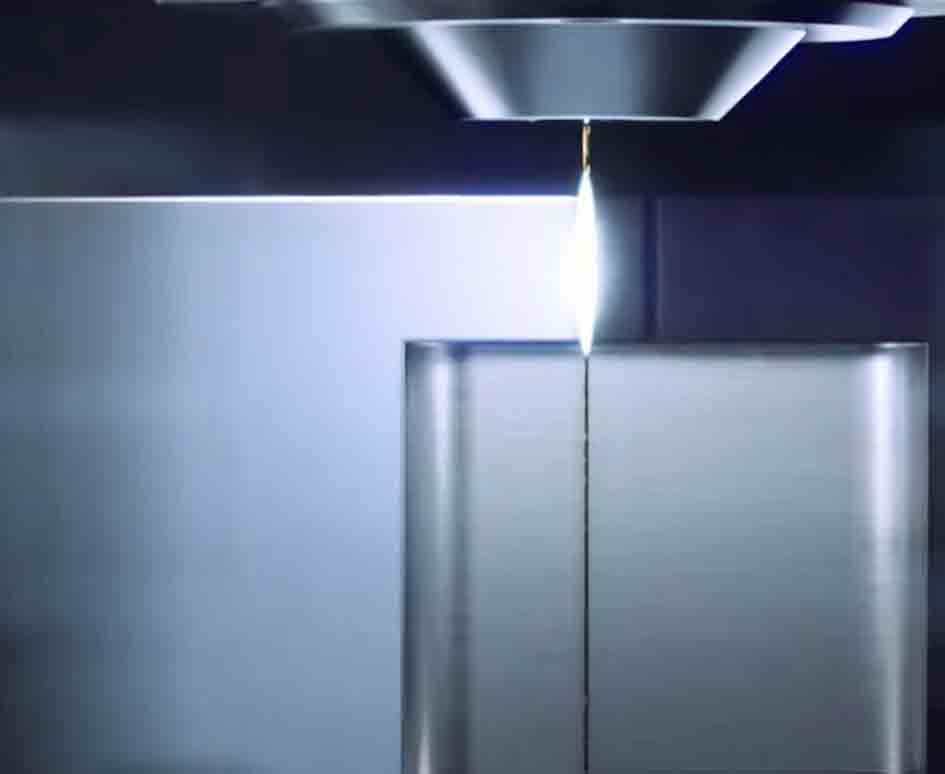

GF Machining Solutions’ new iWire technology automatically adjusts wire speeds to changing part/feature heights and erosion conditions to optimise the wire EDM process.

iWire technology from GF Machining Solutions, available on its advanced AgieCharmilles wire EDM machines, automatically identifies and adjusts wire speeds to changing erosion conditions, helping to eliminate wire breakage and reducing overall wire consumption per job, by over 25%, in some instances.

The iWire function works in tandem with the company’s Intelligent Spark Protection System (ISPS), both being key features of the company’s sophisticated UNIQUA control.

Building on its vast and unrivalled technological knowledge of the EDM process, the company’s EDM machines not only recognise exactly where the EDM sparks are occurring during the process, they can also identify and measure the exact location of each spark along the length of the wire.

Knowing the exact location of a spark enables iWire to automatically adjust the wire spool speed accordingly preventing the chances of wire breakages from occurring.

This is a real and tangible business benefit during lights-out and unattended operations when machining, for example, complex ‘stepped’ parts and/or features that have variable heights.

Both ISPS and iWire help prevent wire breakage and, as a consequence, reduce wire usage helping to control consumable costs and increase machine uptime.

In recent tests, iWire working in tandem with ISPS prevented wire breakage on a part with numerous features with varying heights.

The cut started at a standard spool speed, then when the cutting height reduced, the speed automatically slowed. As a result, wire savings equating to about 480m or 0.2kg were observed, and processing times were similarly reduced, by 30%.

Leave a Reply