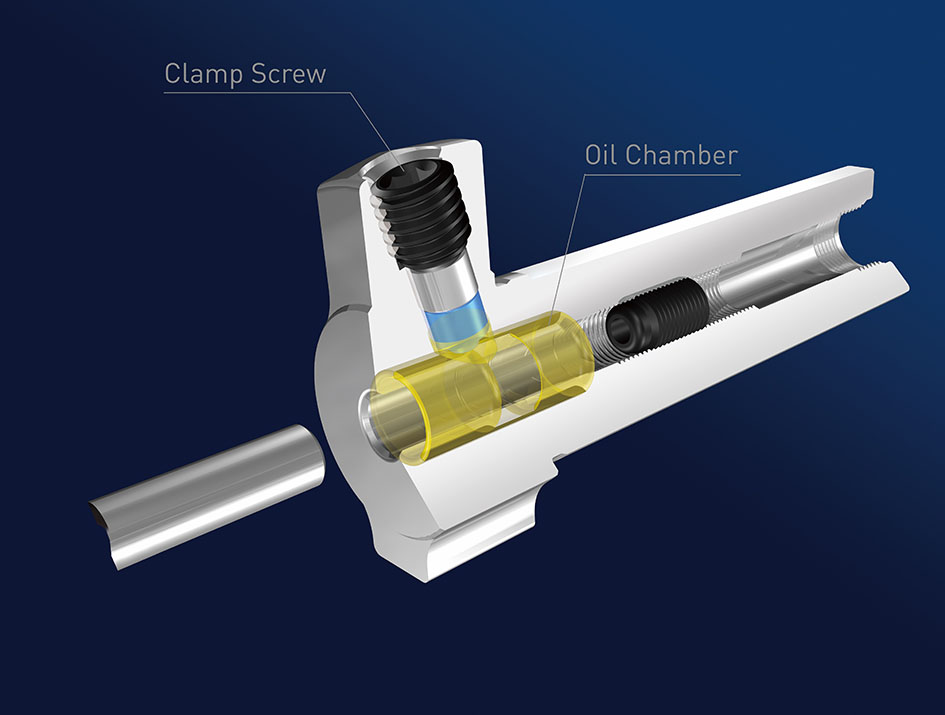

Hydraulic chucks are the most precise chucks that can be used on turning machines, providing outstanding repeatability and damping characteristics. The advantage of the new BIG KAISER chucks that are available from Industrial Tooling Corporation (ITC) is that they enable simple and straightforward assembly using just an Allen key, whilst the holder remains mounted on the machine.

The new BIG KAISER hydraulic chucks for turning are ideal for short and long turning tasks and are specifically designed to be compatible with major sliding head automatic turning centre brands such as Citizen, Star, Tsugami and Tornos. The new chucks are offered in three versions for different application types.

The first is a standard version for typical frontal tool clamping and this is operated from the front of the revolver. The second type, the ‘Type F’ version also optimises tool clamping from the front, but the clamping system operation occurs from the rear. This can be useful in situations where space is limited. The third type, the ‘Type R’ version is used for multiple tool rows and features a square design that prevents interference, which is ideal for platten-type configurations.

Discussing the new system, Giampaolo Roccatello, Chief Sales & Marketing Officer for Europe at BIG KAISER says: “BIG KAISER produces high-end hydraulic chucks for practically all turning machine brands. Our latest hydraulic chuck models deliver the high-quality results that BIG KAISER is renowned for, whilst providing added flexibility for special applications with the Type F and Type R versions.”

The three high-precision hydraulic chucks are available now from ITC.

Leave a Reply