German manufacturer develops ingenious method for relieving the spindle bearings from radial and axial forces when turning operations are in progress on its machining centres. The system provides further spindle protection by supporting heavy driven tools.

During metalcutting, the bearings in a machining centre spindle are subjected to a load from the side and another along the spindle axis, as well as resonance from the cutting process. While the spindle is rotating, the effects of these loads are dissipated across each ball or roller bearing within the spindle assembly. However, when the spindle is static, for example when it is holding a turning tool, the loads and vibrations can cause premature wear and eventually lead to expensive repair or replacement.

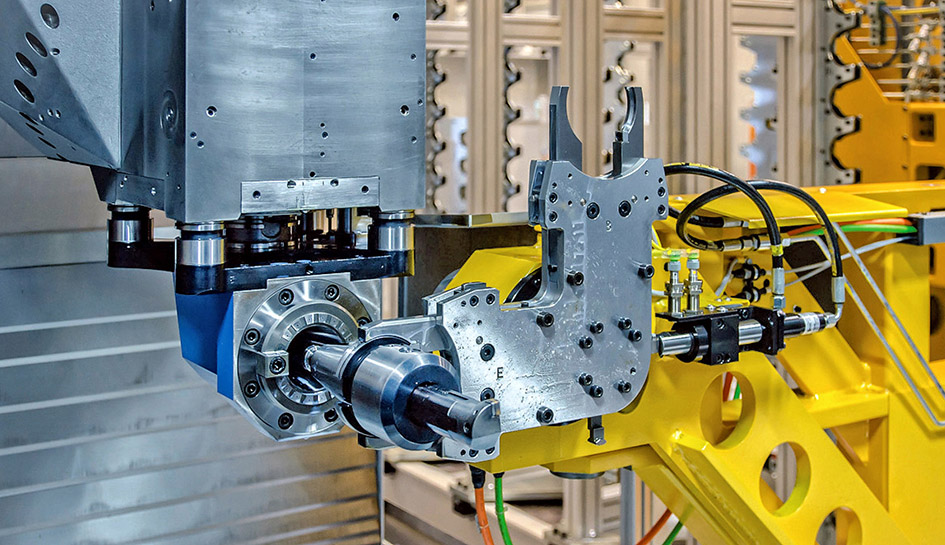

Mindful of this, Burkhardt + Weber (B+W) has introduced a hydraulically-actuated, four-point clamping system on the spindle head of its heavy-duty, multi-tasking machines for use during turning operations. It eliminates both the radial and axial forces on the spindle, the former being particularly damaging and prevalent during facing operations or when grooving or profiling a bore. The result is minimal spindle wear during high accuracy mill-turning of components in a single set-up.

The sole sales and service agent for B+W machines in Britain, Ireland and the Gulf, Kingsbury (www.kingsburyuk.com), has put together a PowerPoint presentation outlining how the system works, a copy of which is available on request. Meanwhile, a video is available to view at: www.kingsburyuk.com/video/burkhardtweber-mct-1000. The content is based on a 5-axis, twin-pallet MCT1000 horizontal-spindle, universal machining centre with 2,200 x 1,400 x 1800 mm working volume. The fourth CNC axis is an infinitely-adjustable, ± 225-degree swivelling head rotating about a 45-degree plane and containing a 41 kW / 8,000 rpm / 1,400 Nm spindle, while a 300 rpm torque table provides the fifth CNC axis.

Multi-tasking on a milling / drilling centre by turning a component on the rotary table with a static turning tool clamped in the spindle in a single set-up is commonplace, but most configurations on the market tend to be based on light- to medium-sized platforms. With the B+W solution, similar technology is available to address one-hit production applications involving much more rigorous machining of larger components made of tougher materials.

Before the turning element of a machining cycle commences, a customisable tool holder plate with a large, 160 mm diameter contact area is transported by the automatic tool changer (ATC) to the four-point clamping system on the front of the spindle head, where the holder is hydraulically retained. The coupling area is thoroughly cleaned with coolant and air before final engagement. As the entire process is autonomous, there is no operator intervention or interruption to the production cycle.

Manufactured in-house at the machine tool manufacturer’s Reutlingen factory, the rigid holder provides full support of static turning tools, absorbing the radial and axial machining loads that would normally be placed on the spindle bearings and transmitting them into the much more robust spindle head structure. Turning cutters are exchanged automatically from the magazine into the adapter in the holder plate using the same ATC, as the identical HSK-A100, SK50 or CAT50 back-end is used for the turning toolholders as for prismatic machining. Even when clamping very long turning tools, the holder plate ensures a rigid tool interface. All operations are fully integrated into the Siemens Sinumerik 840D sl control.

Alternatively, an adapter plate may be similarly delivered by the ATC and clamped hydraulically to the spindle head using the same four-point mechanism. It takes all the weight of a heavy angle head, boring bar, NC facing head or other driven tool needed to carry out special machining operations like drilling multiple or awkwardly positioned holes, facing, grooving, profiling features such as a stepped bore, or turning an internal or external taper or sphere. As the spindle is not subject to excessive moments of force by having to support large cutters, the bearings are protected and are subject to less wear. A three-point clamping system is alternatively available if the tools to be supported are lighter.

As an option, a tool extension unit can be automatically exchanged into the spindle to extend the reach of short cutters, minimising the number of long tools in the magazine that may be needed for certain applications. The unit also provides more rigidity than long-reach cutters, optimising damping and avoiding the risk of vibration and chatter. Quill movement with length and sag compensation is a further option for machining particularly difficult inner contours.

The rotary table on the MCT1000 may be used for 5-axis simultaneous prismatic metalcutting or positioning components for 5-sided machining, but for turning operations its dynamic, backlash-free, 55 kW torque drive rated at 4,200 Nm is its defining feature. Pallet load can be up to four tonnes when turning at maximum rotational speed of 300 rpm. Software is included in the control as standard for actively balancing the loaded table, with monitoring provided by imbalance sensors.

B+W builds its tables with a large INA (Schaeffler Group) ZKXDF or ZKLDF angular-contact thrust ball bearing of diameter between 460 and 725 mm, depending on machine model. Construction height of the table is low despite the high power, maximising the machining envelope. Five-channel hydraulic transfer is possible up to maximum rpm. The table motor stator and rotor are actively cooled by a water-glycol mixture to prevent thermal movement.

The travelling-column machine design allows the X-axis to be hydraulically clamped by a large brake disc during turning for extra rigidity and machining accuracy. As the X-axis does not move during the turning section of a cycle, motion control is drive-friendly and energy efficient. The table bearing absorbs a high tilting moment up to 45,000 Nm. Pallet positioning is to within 10 microns, assisted in part by automatic cleaning of its underside and the pallet clamping surface before exchange.

Leave a Reply