It is acknowledged that run out can be relatively low on some hydraulic chuck systems, and this can diminish further after intensive use. This can now be significantly improved with the new Hydraulic Chuck Jet Through that has been introduced to BIG KAISER’s HDC (hydraulic chucks) series available in the UK from Industrial Tooling Corporation (ITC).

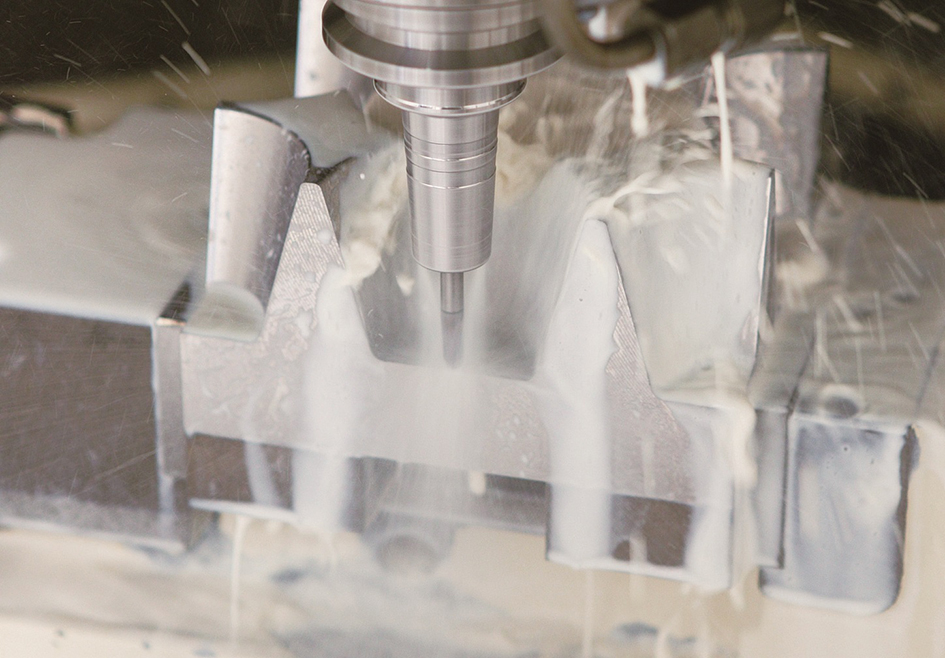

Hydraulic chucks compress an internal membrane in the holder body to apply uniform pressure around the cutting tool that optimises concentricity and minimises runout. Clamping with the new BIG KAISER Hydraulic Chuck Jet Through chuck series is easy, fast and safe. This makes it simple to change tools in the machine. With no heat shrink clamping machines required, the life of the tool holder is extended indefinitely, saving money and reducing the environmental impact of holder replacement when compared to shrink-fit holders. Part of BIG KAISER’s HDC (hydraulic chucks) series, the new through coolant chuck provides precise clamping in the 4 to 12mm diameter range with the extremely accurate and innovative BIG CAPTO interface.

According to Giampaolo Roccatello, Chief Sales & Marketing Officer for Europe at BIG KAISER: “The jet-through hydraulic chucks are ideal for applications that would benefit from improved coolant delivery. By directing coolant to the cutting edge, surface finish is improved and tool life is extended.”

Produced in the high quality that BIG KAISER is known for worldwide, the new chuck is well suited for all small to large machine shops that undertake precision milling where the lowest possible runout is required. The new chuck combines a sleek contour and through coolant capability to deliver significant improvements for the end user. The Hydraulic Chuck Jet Through is available for BIG CAPTO C5 and C6 machine spindles as well as the BBT 30/40/50, BDV40, and HSK 63 spindle interfaces. The Hydraulic Chuck Jet Through is available now from ITC, please contact your local ITC representative for more details.

Leave a Reply