Founded almost 40 years ago, Travelling Wire Ltd was a business that needed updating, until Richard Weller bought the company just over six years ago. Despite its impressive reputation for servicing the toolmaking industry in the South East; a lack of investment was sending the business into steady decline. However, the change of ownership has brought a completely new lease of life to the company, and it has invested heavily – especially in Mitsubishi spark and wire EDM machines from the Engineering Technology Group (ETG).

The company had a raft of ageing technology that included three Mitsubishi FX10 and one FX20 wire erosion machine as well as other EDM machines in the 25 to 30-year-old age bracket. As the new owner of the Burgess Hill business, Richard, a Technical Manager at another toolmaking business, swept in and began to invest in new technology – the results have been nothing short of amazing.

With a dilapidated plant list, Richard started to have a clear out, removing the ageing technology and replacing it with new. As the Company Owner and Managing Director says: “When I bought the business, the immediate issue was that all our wire and spark erosion machines needed constant attention. The wire would break multiple times each day on every wire EDM machine, meaning the shop floor staff would have to re-thread the wire and re-start the job from the start of the program. Likewise, the spark erosion machines could only spark one hole or feature at a time and operators would have to re-set the machine for the next operation. Added to this, the old machines would constantly need maintenance and ‘running repairs’ to keep them going. We needed to do something – and rapidly.”

The Mitsubishi MV2400R and SG12S

The Mitsubishi Solution

In his previous business, Richard had decades of experience with Mitsubishi EDM machines – so he immediately called upon Scott Elsmere, the resident EDM expert at ETG. Following the departure of some of the FX machines, Travelling Wire was left with an outdated Mitsubishi FX20 good BA8 machine running alongside a machine from another vendor. The business was struggling to meet its customer commitments. Following a conversation with Scott, the subcontract manufacturer purchased a Mitsubishi BA24 wire EDM in 2019.

“The difference to our old technology was amazing. If I was to describe our old machines, I would say it was like having a car where ‘the handbrake doesn’t work’ or you are ‘running without lights’, there was always an issue that created inefficiencies. The BA24 had automatic wire re-threading and this instantly enabled us to run our wire EDM unmanned overnight. The machine we replaced needed wire re-threading constantly, and whilst this only took 5 minutes – it meant we always had to be watching the machine. The BA24 was saving 20-30 minutes a day in re-threading time alone. Add in the 50% productivity increase as well as the unmanned night running – the difference was huge. We erode a lot of tungsten carbide and one job that took 24 hours to process unmanned on the BA24 would have been a minimum of 3-days on an older machine.”

From 2018 to 2022, the company continued to invest, acquiring a new CNC milling machine, a new manual mill, CMM, a large surface grinder and a rumbling machine for deburring parts. One factor that made a difference was the commitment to becoming ISO: 9001 certified. As Richard adds: “Historically, the company had been servicing toolmaking businesses and general subcontract manufacturers. ISO: 9001 won us business with new customers and simultaneously, the Mitsubishi BA24 improved our productivity and quality to meet the demands of our growing customer base.”

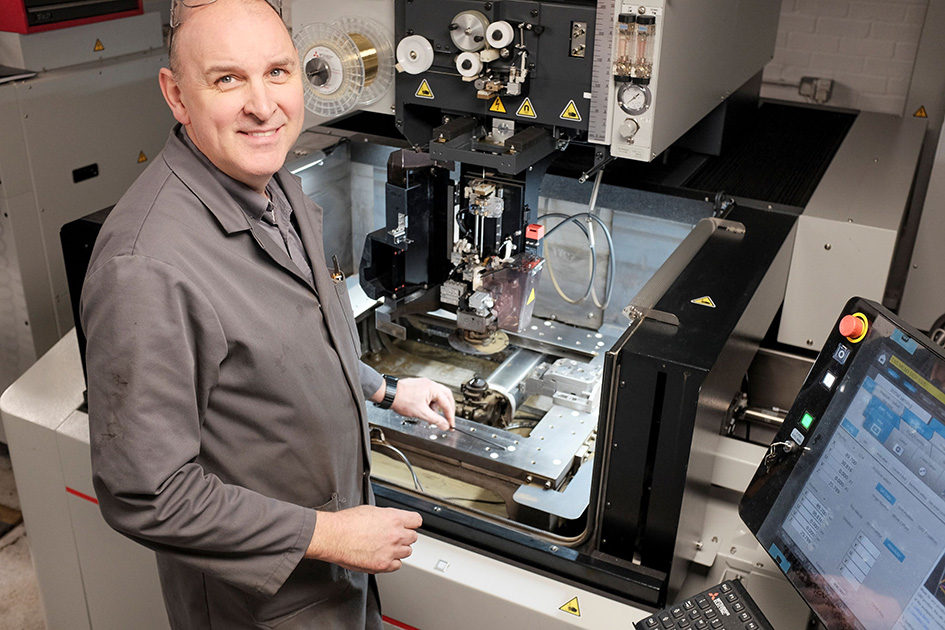

Toolmaker Chris Weller Operating the Mitsubishi SG12S Spark Erosion Machine

Whilst the Mitsubishi BA24 and BA8 was an improvement upon previous machines at Travelling Wire, the machines was regularly running at capacity – carrying the load for the business with a few ageing machines alleviating any remaining capacity. To continue its growth trajectory, the company needed to invest in more EDM technology. So, in November 2022, the company took delivery of a Mitsubishi SG12S spark erosion machine and a Mitsubishi MV2400R wire erosion machine.

Looking at the new Mitsubishi SG12S spark erosion machine, Richard says: “This machine has been a complete game-changer. We had an old machine that had an auto-tool changer, but it didn’t work well. Setting up the old machine was a cumbersome task and it was difficult to use. Every time we needed to conduct a secondary task, we’d have to manually change tools and re-set the machine. The Mitsubishi SG12S has eliminated all of this with its 20 position tool changer. ETG also supplied a lifter table and magnets, Erowa toolholders and a probing system as part of our package – the additional investment was worth every penny.”

The additional equipment accelerates set-up times and the on-machine probing system significantly improves precision and repeatability. As Richard adds: “Three of our team had 3-days training with ETG on the new Mitsubishi SG12S, and during the training, we learnt a lot of new methods for working as well as gaining an understanding of the machine. We also invested in the Esprit CAM software system from ETG and this has also enabled us to improve our workflow.”

“Whilst the toolholding and CAM investment have made improvements to our set-ups, the major difference is when parts are running. Not only are our cycle times at least 50% faster, but the machine will run uninterrupted for long periods. We recently machined 18 parts and each part needed a slot sparked. On the old machine, this would have been a minimum of 36 re-setting interventions, but on the Mitsubishi SG12S, the parts were probed and the machine completed the job with no interventions.”

Alongside the new SG12S is the new Mitsubishi MV2400R wire EDM. Alluding to this investment, Richard says: “We thought the BA24 machine in 2019 was a step up from our previous technology, but the MV2400R is at least 40% faster than that machine. The MV2400R is a brilliant machine. The wire continually re-threads with precision, there are no maintenance issues, the set-ups are fast and stable processes, and the touchscreen control and software are just amazing to use. The MV2400R is giving us a huge capacity boost with its ability to work around the clock at speed with minimal downtime. Furthermore, the quality of the finish is exemplary.”

In conclusion, Richard says: “The new machines have transformed our business and there is so much more to come. The quality and precision of our work has improved, and with the enhanced capabilities of these machines, we are winning more contracts from the end-users – the automotive, food and pharmaceutical manufacturers that demand quality at the highest level. Not only can we exceed the expectations of these new customers with the Mitsubishi machines, but we can also supply shorter lead times with more competitive pricing. I absolutely love the Mitsubishi brand and the technical support from ETG has been outstanding.”