At AMB 2022, German lathe manufacturer INDEX launched a new twin-spindle turn-mill centre with 76 mm bar capacity, 230 mm chuck diameter and a turning length up to 900 mm. The TRAUB TNX220 has a vibration-damping mineral cast bed and generously dimensioned linear guideways in the X and Z axes, a combination that delivers accurate machining and high productivity.

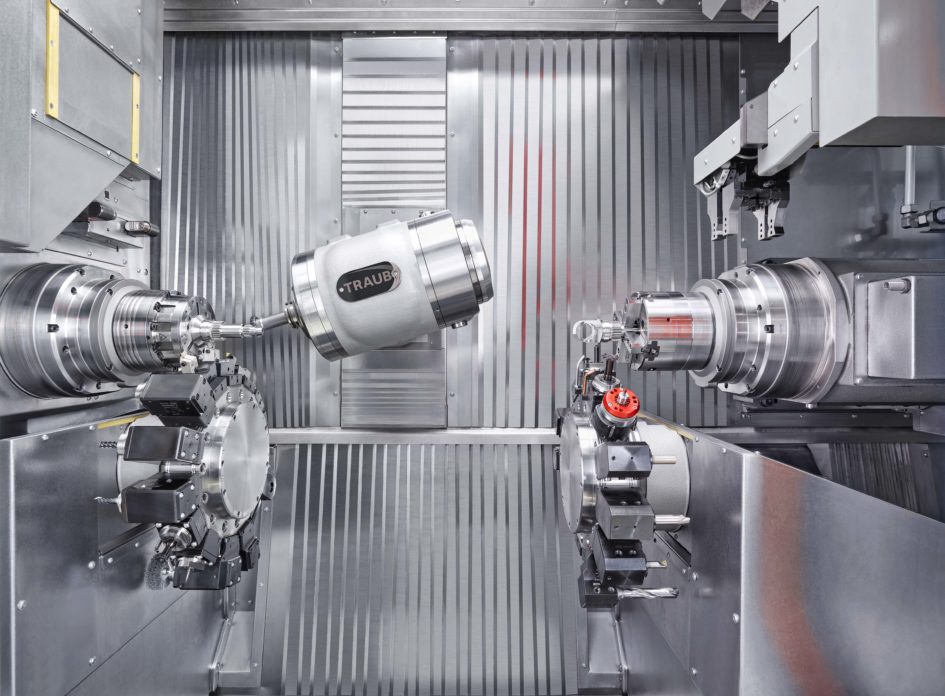

With a powerful Y/B-axis tool spindle rated at 40 kW, 207 Nm, 6,000 rpm above the work spindle centreline, and two 12-station (VDI30) or 15-station (VDI25) live turrets below, the lathe is ideal for one-hit machining of complex parts in cycles that can include 5-axis milling.

The top tool carrier is served by a magazine with 139 positions for HSK-T63 or HSK-T40 cutters. The tool magazine can be accessed from the front and also from the rear, from where one of the two magazine chains can be replenished while the other is in use.

The two lower tool carriers also have Y-axis movement in addition to X and Z axis travels and every station is driven. All tool carriers can operate simultaneously at either of the identical, fluid-cooled main and counter work spindles, which are also rated at 40 kW, 207 Nm, 6,000 rpm.

Automation options include an INDEX MBL 76 bar feeder, which has been tailored to match the new machine design and is quick to change over to a new size of stock. The loader features excellent damping properties as well as easy setup and is purely electrically powered, so does not require hydraulics.

An integrated gantry-type loader with a double gripper and/or an INDEX iXcenter robot cell can be used to automate load / unload of billet or shaft parts. The control system is a modified Mitsubishi TX8i-s V8, which is easy to operate via the iXpanel cockpit solution.