Norgren, part of IMI plc, is debuting Adaptix™ Soft Jaw, its unique universal soft jaw solution on stand 17-221 at MACH 2022 taking place between 4th and 8th April at the NEC, Birmingham.

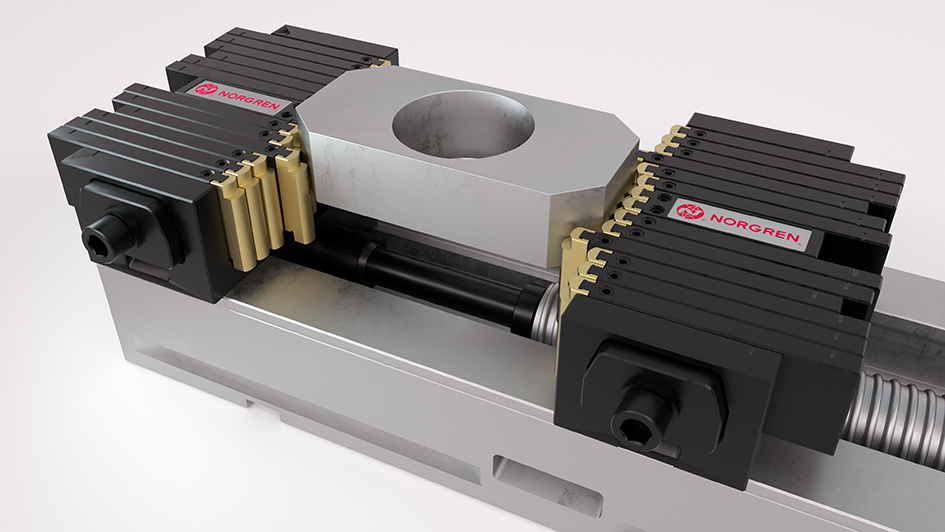

Offering the same robustness as a traditional aluminium soft jaw, Adaptix™ Soft Jaw adapts to flat and unique part geometries to provide the necessary forces to hold the workpiece securely. Its ease of configuration and interchangeable pin tips mean machine operators can radically reduce set up and changeover times and their associated labour costs.

As well as the opportunity to investigate the revolutionary Adaptix™ Soft Jaw solution in action, visitors to the Norgren stand can also see the wide range of supporting system components such as tips and stud, which enable the soft jaw to adapt clamping forces and grip dependent on the material.

Norgren’s team of expert application engineers will be on-hand to answer technical questions, as well as demonstrate its bespoke ROI online tool which can calculate an instant return on investment for Adaptix™ Soft Jaw compared to traditional soft jaw solutions.

Tom Wood, Senior Director, Growth Initiatives at Norgren says: “We are delighted to unveil Norgren’s unique Adaptix™ Soft Jaw to the UK market at MACH. It is the first universal soft/vice jaw solution that offers the same high force, repeatability and unbeatable accuracy as a traditional aluminium soft jaw yet can adapt to most part shapes.

“It delivers game-changing time and cost saving benefits for the CNC market by eliminating the need for an extensive soft jaw inventory and the provision of ultra-quick new part shape adjustment to aid production efficiency objectives. With built-in flexibility thanks to an array of interchangeable pin tips and a guaranteed performance level for clamping forces, users can add it to their tool portfolio with confidence.”

To support Adaptix™ Soft Jaw, Norgren has developed an in-depth white paper specifically for the machinery market, outlining the solution’s impressive features, together with the tangible benefits machine operators can realise with it.

For more information visit: www.norgrenworkholding.com