When Pro-Cut Precision Engineering Ltd opened its doors for business just over 10 years ago, the objective was to invest in the very latest equipment to ensure the Milton Keynes business could machine high-quality components with short lead times. As a company that has acquired a multitude of 3 and 5-axis Hurco machine tools for machining complex parts, part programming was becoming a time-consuming process – that was until the Milton Keynes company invested in the hyperMILL® CAM system from OPEN MIND Technologies.

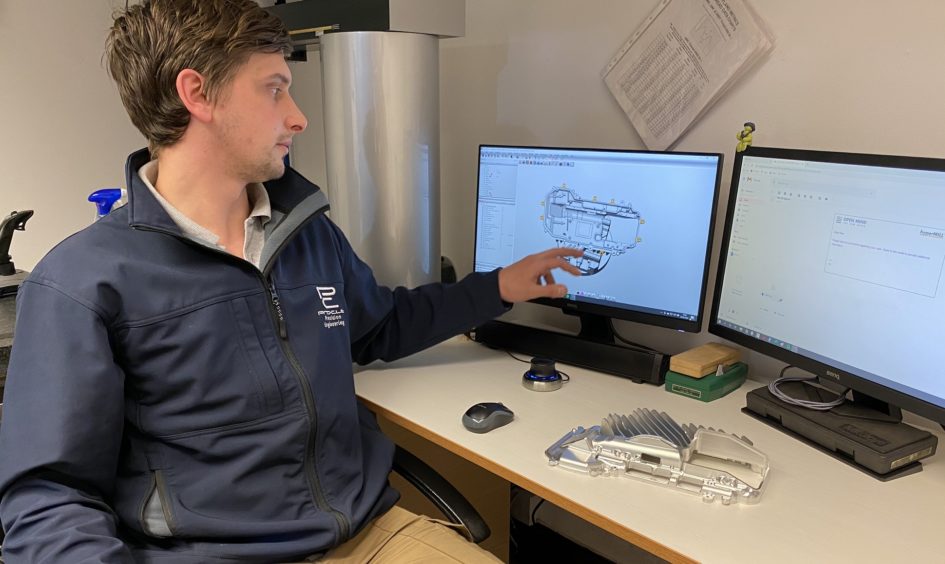

The Little Horwood subcontract business works across several industry areas, serving the F1 and motorsport industry, the defence sector, industrial machinery and components and also the specialist high-speed imaging and microwave market. Explaining the reasoning behind investing in OPEN MIND’shyperMILL® CAM software, Pro-Cut Precision Engineering’s programmer, Mr Alex Parris-Hammons explains: “We previously had a CAM system as well as programming many components on the machines, but we found that we were losing time by not being able to stay ahead of the game. hyperMILL® allows you to program off-line and do all the programming whilst the machine is still doing a current job. This enables us to build a queue of future jobs.”

“With our previous CAM system, we were doing 5-axis work with it, but we found the collision detection wasn’t that great. In fact, we’ve had to lie to the software system to get it to produce the parts we needed. With hyperMILL® that isn’t the case; it identifies where the collisions are, both in an internal and external simulation. It gives you a list of where the collisions are, and it makes it so simple to correct any problems that we have. hyperMILL® gives us confidence. hyperMILL®

is very well known for its collision detection and with that, you can trust the billets going on the machine will come out as 100% correct parts,” says Alex Parris-Hammons.

Now with two seats of hyperMILL®, Alex Parris-Hammons recalls the initial installation of hyperMILL®: “The plan was to use hyperMILL® initially for simple components and then build-up to the full capacity of hyperMILL®, which is the 5-axis simultaneous toolpaths. This would give us better surface finishes and faster machining times. In the early stages, I have called the OPEN MIND technical support team and they have been able to walk me through any scenarios by using Team Viewer and a telephone call to resolve any issues.”

Steve Holmes, Managing Director at Pro-Cut Precision Engineering recalls: “We purchased hyperMILL® a little while ago actually, and Alex had done the training, but we naturally kept falling back to our existing provider due to tight deadlines and several other factors. For a little while, hyperMILL® was just sitting there, but then this one particular part came along! It was a challenging aluminium electronic casing part that was outside the scope of our current CAD/CAM system. So, we decided that this was the part that we begin with, where we jump in and manufacture with 5-axis simultaneous hyperMILL®machining. This is the first part that we produced using hyperMILL® and it was absolutely bonkers – and we only had two weeks to complete the 3-off batch of parts.”

“This made hyperMILL® a very quick learning curve. However, the one thing I will say about OPEN MIND is that their support is absolutely phenomenal.Once we got going on this part because it was so complex with simultaneous machining that we hadn’t done before; every time we got stuck, we would phone OPEN MIND and they would either deal with the situation there and then, or they would come back to us very quickly. There was no ‘phone up and sort it in a couple of days’ – every issue was resolved ‘there and then’. I was genuinely amazed.”

Adding to this, Alex says: “It was a very steep learning curve, but it is what we needed to do to decide that we were going to use the software, knowing we would have to learn how to use it very quickly to complete our first job.”

As the programmer that was tasked with creating the program for the complex aluminium electrical housing part, Alex highlights the features that stood out with remarkable ease of use: “The 5-axis and the Z-level finishing is very good with this software. You just have to click on a surface, and hyperMILL® will machine that surface. Once you understand how it works, it is very easy to actually use and get up to speed with. It means you can quickly reach competence level where you can do complex work much easier.”

“The tool library is also very good. It allows you to input a lot of information on each tool and the respective holder. When you put that information into the system to do the simulation, it will then calculate whether it is going to collide with your workholding, fixtures or the machine. It will detect and protect itself.”

Taking a closer look at the electrical housing part, Alex says: “For the first operation we held the part in a Lang workholding vice, machined the top and all of the internal sections as well as the outside profiles. This first operation alone required upwards of 25 tools and the hyperMILL® tool library keeps that information ready, so you can access it for other upcoming jobs. This makes the whole process of programming a lot quicker and easier.”

Discussing potential collisions and tool path and strategies, Alex says: “With the tool library you can set up your tool length and how far the tool is sticking out of the holder, that data is used when hyperMILL® is calculating. This avoids collisions and also tells you how much further the tool needs to stick out to avoid a collision.”

Following the first operation, the aluminium housing was turned over for machining on the opposite face. Highlighting this, Alex says: “We made a fixture plate to locate on the inside of the component and we threaded the tabs to pull down the periphery of the part. On the second side of the part, we used 6 tools. Programming the part took a couple of days. However, now that I have undergone a steep learning curve and I know what to do, programming similar future components would take significantly less time – we could probably program this part in half a day now.”

“Previously, this part would have been very difficult to program without hyperMILL®. The second side of the component would have undoubtedly made our previous CAM system crash a lot as there is a lot of information and a lot of code being produced. With hyperMILL®, we have machined the complete component in just 15 hours. Now that we have used this very complex part as the first push to get onto hyperMILL®, we are very pleased that we are using it effectively for all of our parts.”

Concluding on why the company opted for hyperMILL®, Steve says: “Our previous system had its merits, but it didn’t have the process security, collision detection and avoidance and it would have been incapable of the complex 5-axis work that hyperMILL®, can breeze through. On the shop floor, it’s still early in our learning curve to qualify all the benefits, but we can already see that it is improving surface finishes and. Additionally, when we are rough machining, there is no ‘fresh air cutting’ with hyperMILL® – our previous system didn’t have this level of intelligence to make it as efficient. This will certainly create cycle time savings in the future. hyperMILL® really is the next level.”