With the arrival of the new 222 System of turning and grooving tools, Guhring has extended and defined its position as an industry-leading supplier of full-line turning solutions. The new parting-off line demonstrates productivity, efficiency and performance parameters beyond its rivals.

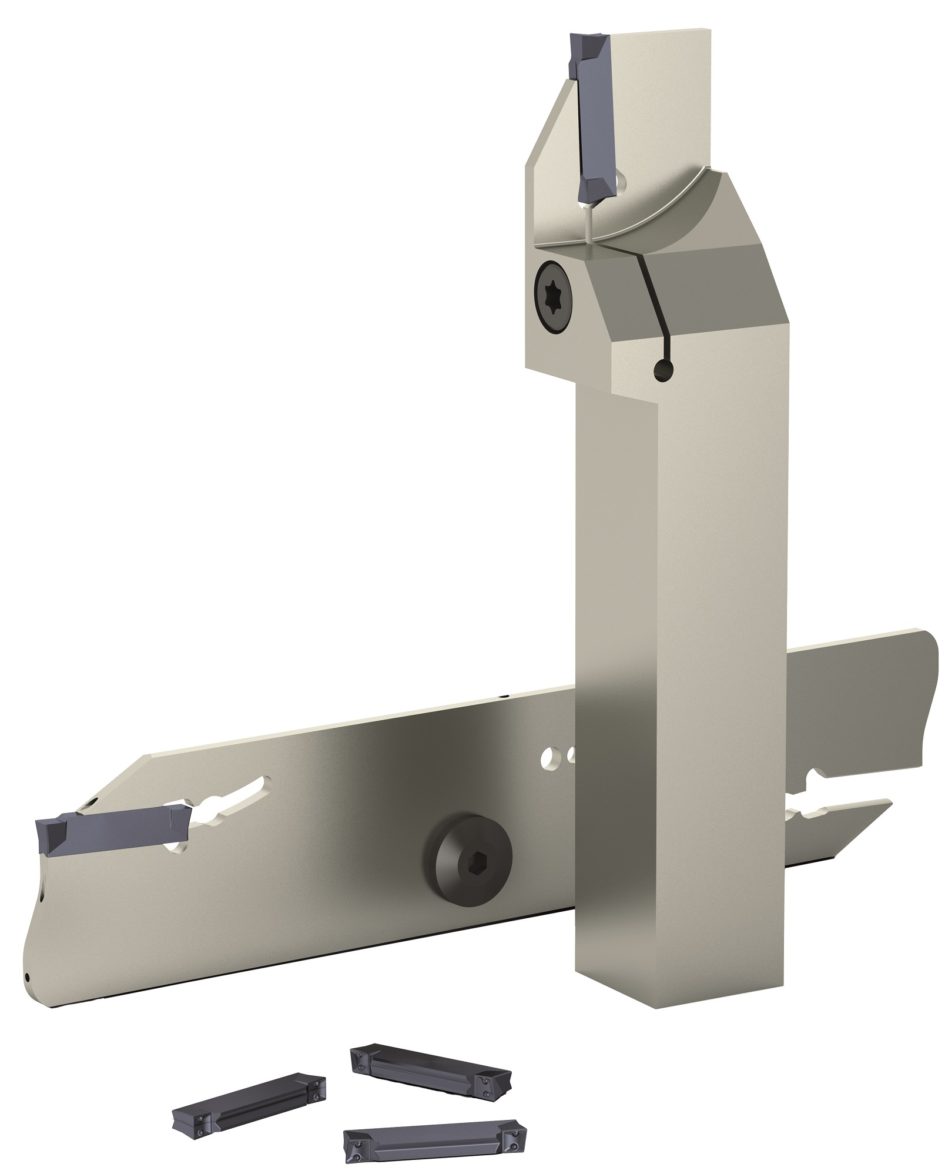

Incorporating an extensive line of indexable inserts and tool holders, the new 222 Series provides a productive and cost-effective solution for all material types and applications. The 222 designation is derived from the 2 cutting edges with an effective depth of cut up to 22mm. The 222 System is available with both a tool holder or as a blade type to suit the demands of the end-user. The dedicated tool holder is nickel plated to present extended tool life and longevity with three internal coolant supply channels to suit the specific set-up of the end-users machine tool and coolant supply configuration. High-pressure coolant delivery is supplied to the cutting edge via two channels that are positioned both above and below the cutting edge. This design extends tool life, performance and it also supports chip breaking and evacuation.

The tool holders are available in left and right-hand designation with tool body dimensions from 12 by 12mm up to 25 by 25mm, making the new 222 System suitable for everything from small compact turning centres and sliding head machines through to large more robust machine tools. The impressive tool holders can be selected in overall body lengths from 108mm to 152mm depending upon the tool selected. Rigidity and performance are further assured by a tool design that also incorporates a new clamping screw design and insert support that guarantees maximum insert clamping torque and stability during machining.

Like the tool holder designation, the nickel-plated blade type tool holder is available with and without through coolant facility with a blade length of 120 or 150mm, a height of 26 or 32mm and a width of 2.25mm depending upon the selected tool. The new blades are compatible with existing Guhring blade holding tools as well as industry-standard blades from alternate manufacturers.

The pressed-to-size solid carbide indexable inserts are coated with Guhring’s innovative proprietary Fire coating technology that demonstrates outstanding performance and longevity. The insert grades provide stable and consistent machining on carbon steel, low and high-alloyed steel, cast steel and stainless. The double-edged inserts correspond with the tool holders with neutral, left and right-hand variants available. Guhring has developed the 22mm long and 3mm wide inserts with an optimal chip breaking design that creates a smooth cutting action and reduces cutting forces.