GF Machining Solutions has introduced the Mikron MILL P 800 U ST* machining centre, which integrates milling and turning in a single machine to its impressive machine tool portfolio. (*The ST suffix designates it as a ‘Simultaneous Turning’ machine).

Highly efficient, the compact machine provides 800 mm of X-axis travel, an 800rpm C-axis rotation speed and a maximum table load of 800 kg.

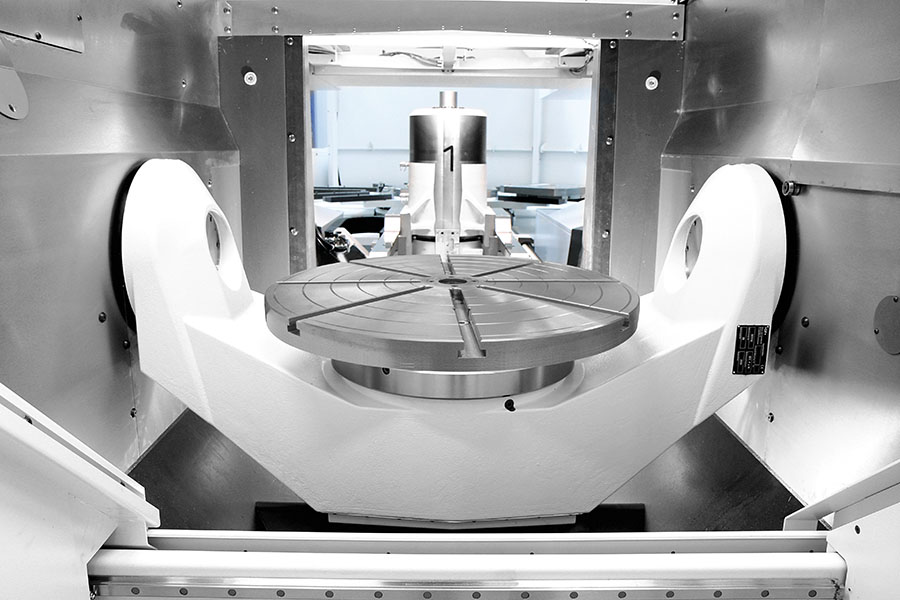

The MILL P 800 U ST was designed with its gantry-type concept as a direct response to the needs of component manufacturers serving the automotive, aerospace, energy and general machining industries. The machine’s small footprint makes it easy to integrate into facilities where space is at a premium – and is able to replace two machines involved in a machining process.

The combination of milling and turning technology in a single machine helps manufacturers improve productivity, accuracy and cost effectiveness. The MILL P 800 U ST achieves perfect workpiece roundness, superior surface finishes and high material removal rates. As such, according to Martin Spencer, GF Machining Solutions (UK’s managing director), “the machine represents great value.”

Being able to fully machine components on a single machine also eliminates transfer-related part run out and accuracy errors, and helps eliminate production bottlenecks.

The 5-axis simultaneous MILL P 800 U ST is also capable of four-axis simultaneous turning, a capability often required by customers that need to have the cutting tool positioned at a 90-degree angle to the workpiece surface to avoid tool shape errors. The machine incorporates a 20,000rpm HSK A63 spindle that is the industry’s fastest for a milling and turning machine of this size.

Additionally, water-cooled torque motors on the A-axis and C-axis ensure accuracy and stability, while speed is enhanced through the axes’ 0.3-second clamp time in any position.

With the new machine’s gantry concept, the workpiece on the 500mm x 730mm table is fully accessible without rotating the table. This eliminates errors related to table rotation and avoids the need for hand polishing. The tool changer for the machine is also located so as to avoid moving the table during tool changes.

GF Machining Solutions’ Machine and Spindle Protection (MSP) facility adds security to the machining process by protecting the machine and spindle against crashing during setup and machining. As the only system on the market to offer protection in all directions, MSP eliminates spindle damage, misaligned machine geometry, downtime and costs related to unexpected spindle crashes.

The MILL P 800 U ST is automation ready and equipped with pallet changers for 2, 7, 9 or 12 pallets. It can also be easily integrated into existing automation systems, including System 3R automation solutions.

It can be supplied with either a Heidenhain or Siemens control and up to a 215 position ATC.