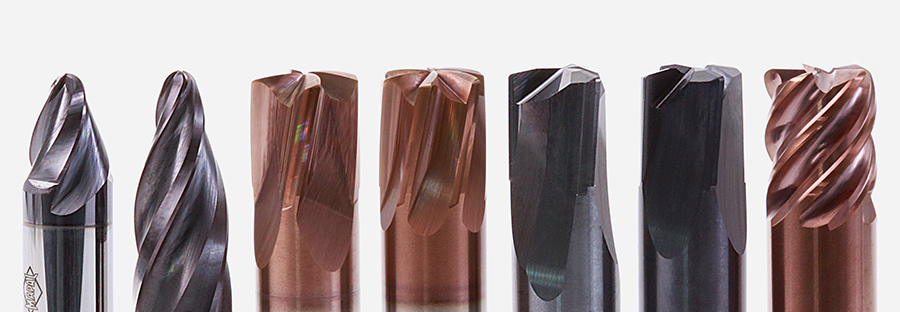

MAPAL has now introduced a completely new line of high-performance solid carbide end mills. The new OptiMill-3D series is a new programme of solid carbide milling cutters specially developed for the tool and mould-making industry. Along with extremely heat-resistant coatings and special carbide substrates, the new tools are characterised by the dimensions and geometries specifically adapted to mould making.

High-feed machining with high material removal rates

Suitable for milling hard parts in the domain of 45 to 66HRc, the new OptiMill-3D-HF-Hardened is the new tool of choice. Offered with four or six cutting edges, MAPAL has developed the two variants for high feed milling on, particularly challenging materials. To optimise performance and longevity on challenging tasks like interrupted cutting, MAPAL has developed a special face geometry.

The four-flute tool is the primary choice for roughing and pre-finishing. However, with fewer cutting edges and a wider chip gullet, rapid and reliable removal of swarf is ensured. Available from 2mm to 16mm diameter, the 4-flute tool is ideal for long overhang applications such as machining in deep cavities.

Also perfect for roughing and pre-finishing, the 6-flute series demonstrates impressive characteristics when finishing flat surfaces with a high feed rate. It produces the best surface finishes and flatness, and with a PVD coating, the tool dissipates heat generation to ensure tool life is prolonged. Available from 6 to 16mm diameter the OptiMill-3D-HF-Hardened is complemented by the three and four flute OptiMill-3D-HF for softer material machining.

Highly accurate corner radii for maximum precision

Also new to the solid carbide range is the new OptiMill-3D-CR-Hardened with a corner radius. Perfect for finishing 3D mould tools up to a hardness of 66HRc, this line produces smooth, high-gloss surface finishes when machining at maximum feed rates. Offered in diameters from 4 to 12mm with highly accurate corner radii of 0.5mm, 1mm and 2mm, the PVD coated OptiMill-3D-CR-Hardened is available with a selection of different lengths and corner radii to suit the machining demands of the end user.

Efficiency in pre-finishing and finishing on 5-axis machines

The new circular radius milling cutters that are also known as ‘conical barrel tools’ have now arrived at MAPAL in the form of the OptiMill-3D-CS series. Perfect for mould making applications in deep cavities, complex free-form shapes as well as the manufacture of turbine blades and impellers – the new OptiMill-3D-CS series is a game changer in productivity and performance.

The special feature of the tools is the optimal geometric combination of radius and form that makes a larger path spacing during pre-finishing and finishing possible. The machining time can be significantly reduced and the quality of the surface finish on the parts significantly improved. For machining deep, difficult-to-access cavities, the OptiMill-3D-CS in droplet shape with diameters from 2 to 12mm and an effective radius up to 95mm is the first choice. For machining large surfaces and surfaces with tool restrictions, the cutter is also offered in a tapered shape. The tapered shape tools are available from 6 to 12mm with an effective edge radius of up to 250mm. The conical barrel tools require a high-performance CAM system to work effectively. However, the combination of a suitable CAM system and the MAPAL barrel tools can yield performance and material removal rate increases in the realms of 70% and more. For further details, speak with a MAPAL engineer.