Like many manufacturing processes, injection moulding (IM) can benefit considerably from automation. But particularly in this current climate where the non-life-sustaining businesses are having to close their doors, workers are self isolating and supply chain complications and higher demand for medical and infection prevention parts is impacting planned production schedules.

The good news is robotics was already quite commonplace in injection moulding facilities before this health crisis commenced. No longer the preserve of a medical operators with specialist needs, statistics released by the European plastics machinery organisation EUROMAP shows that the number of IM machines sold equipped with robots rose from 18% in 2010 to almost a third (33%) towards the end of 2019. Additionally, OPC Unified Architecture (OPC/UA) has been more widely adopted, offering moulders broader connectivity and remote management options, which many operating skeleton workforces may value more now.

Nigel Flowers, managing director at injection moulding machinery supplier Sumitomo (SHI) Demag UK comments: “There has been a significant upwards trend towards automation in plastics processing in recent years. Part of this has been driven by demand for more flexible solutions, so the use of 6-axis industrial robots in precision moulding especially is certainly more commonplace today. Additionally, the price gap between Cartesian and industrial robots has closed markedly, while at the same time, they’ve become easier to programme and simpler to integrate.”

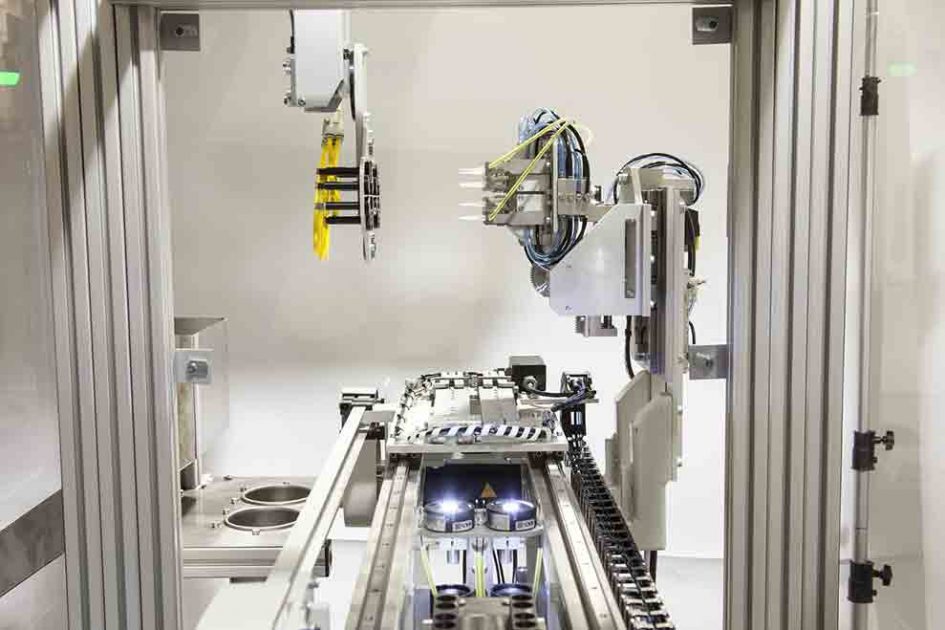

In precision moulding applications, robots are usually chosen for their range of operation, accuracy, repeatability and cleanliness. Sometimes the customer needs to transfer parts, insert load, apply labels or remove complex parts in non-linear movements. For packaging, robotics is primarily used to make customer applications run faster and more cost-effectively. With take-out times of 0.5 seconds or less, it can sometimes be faster to use a robot to remove parts than to let them fall under gravity.

Coping with COVID-19

These are unprecedented times. As cases in the UK rise, self imposed isolation and quarantining will no doubt cause significant labour shortages in the plastic and wider manufacturing industries. Yet, automation can assist moulders to maintain an element of ‘business as usual’ and flex to different production requirements.

Being able to operate around the clock inevitably increases productivity and consequently profitability. But for now, the engineering and manufacturing community is focused on supporting government efforts to ramp up medical supplies. A report published by the British Plastics Federation on 20th March 2020 reveals that one third of companies in the plastic industry could potentially use their facilities to provide products and services that could be used by the NHS or the government to help fight the coronavirus. This level of flexibility will be aided by automation solutions already in situ emphasises Nigel.

He comments: “Already, a large number of manufacturers and component engineering specialists are offering their skills in moulding, casting, forging, assembly, CNC machined parts, pressings, electronics, tube manipulation etc. to scale up manufacturing capacity. There’s been a concerted effort, with companies who were previously competitors forming consortiums to develop a ventilator prototype.” Additionally, there’s heightened demand for oxygen sensors, blood monitoring equipment and facemasks, as well as test kits.

Similarly, the coronavirus outbreak has had a profound impact on the packaging industry. The BPF survey reports a 56% increase in demand for products and services among packaging companies. Already, many organisations that committed to reducing their reliance on plastic packaging in 2020, have switched back from reusable containers and unwrapped goods to single use plastic. “Although this spike is likely to be temporary, packaging moulders are reporting higher demand for caps, closures, pump dispensers, food containers and healthcare solutions, such as wipe lids,” comments Nigel.

Most of today’s industrial robots are not designed for a single application. The result is if moulders need to adapt their equipment, reprogramming a robot to support different products is usually relatively easy and can often be performed by a skilled engineer in house, notes Nigel.

For hygiene sensitive markets, such as medical and healthcare, it is possible to attach a robot to the frame of the IM machine, enabling manufacturers to automate functions like handling and packing within a compact and enclosed cleanroom-standard cell. “Once you have the filter and laminar airflow, the robot is sitting in a cell that’s cleaner than the average operating theatre!” exclaims Nigel.

The industry’s ability to adapt is being thoroughly tested right now. Yet, production goes on. “As an industry, we are united in our focus to stay operational, look after the welfare of our workforce and support the concerted efforts to produce life-sustaining healthcare and other products essential to everyday life. Automated systems and moulding processes will be integral to this effort,” ends Nigel.

http://uk.sumitomo-shi-demag.eu/