Mould Maker Kavia Tooling Combines EDGECAM With a CMM and Customised Software

Mould maker Kavia Tooling uses a Hexagon Coordinate Measuring Machine to create an offline Zero Transfer system ahead of the manufacturing process for parts and electrodes. This considerably reduces downtime on their CNC and EDM machines when setting up new jobs.

Production Director Mark Cole says some components are particularly time-consuming to set up traditionally on machines…and even simple parts mean the machines are idle during set up. But Kavia’s unusual use of the Hexagon CMM means the machines are cutting another job while the set up for the next one is being carried out.

“Hexagon customised the flexible PC-DMIS software which comes as standard on their measurement devices, to enable us to use it to find offsets at the beginning of the operation. Instead of having to put each part on the machine and then set it, we set it on the CMM which gives us the X, Y, Z, and U orientation. We only have to put the Zero Transfer Plate, which is micron-accurate, into position on the machine, and it knows exactly where the part is.”

This can be done with any number of components, thanks to another piece of customised software which Kavia Tooling devised themselves and which engineers from their CAM system, EDGECAM, developed for them. EDGECAM drives seven high-speed CNC mills with spindle speeds varying from 12,000 to 30,000 rpm, and a Sodick EDM machine.

“But it’s no ordinary machining process thanks to the customised software which we call Merge. It collates data from all programs for the job and merges them into a single file, many at 36 megabytes and containing around 1.5-million lines of code. It includes the EDGECAM NC code, datums to set the parts on, Zero Transfer, and cutter tool heights.”

He cites an example when they were working on two cavity plates on one side of the machine, and four inserts on the other. ”We put the individual EDGECAM CNC programs for each component together into one file, and it all went to the machine as one large program.” It also keeps cutting tools to a minimum, by looking at information such as duplication, length and quality of the tools in all programs. “If there are two repeating cutting tools in the individually merged program, it selects the best one for the manufacturing process. It goes through every single NC program and rearranges all the tools accordingly.”

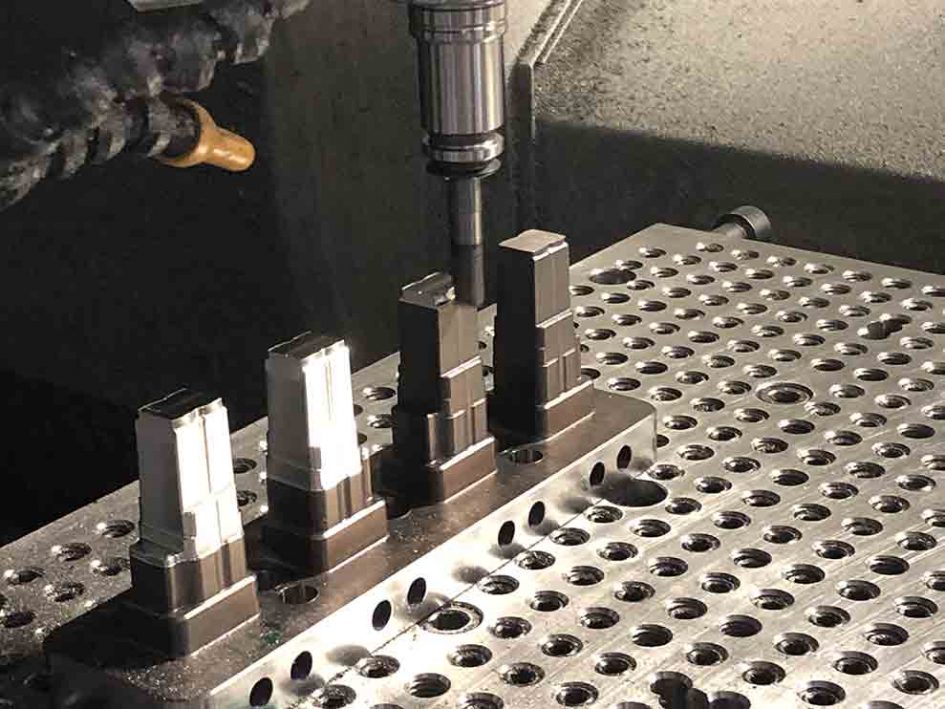

The end result of using Merge with the Zero Transfer Fixture Plates created on the CMM is a CNC program which can machine several parts at a time without the need to use the machine as a set-up station, as all preparatory operations are carried out offline. “If we were setting up a component to be square, directly on the CNC machine tool without the CMM, we’d have to ensure it’s perfectly in line with the machine’s axis. Doing that for ten components considerably increases the risk of error, especially where there are overhangs. But setting them on the CMM means everything is automatically correct, because it tells the machine the angle of each part.

“To set up six fairly difficult components directly on the machine may take one day, during which time it’s not running. But it’ll only take about an hour on the CMM, and we can be confident that they’ll all be absolutely accurate.”

He says that while the Merge software combines with the CMM Zero Transfer system to get the best out of their CNC mills, they gain even greater benefits from using it on the Sodick EDM machine. “This machine used to be our biggest bottleneck. We had to set the electrodes and the part on the machine, and program it by hand typing figures directly into it, which led to errors. It was an absolute nightmare. But when we developed the Merge software it went from being the largest bottleneck to the fastest machine in the factory. And it’s all mistake-proof – there’s no typing as everything’s done from the CAD dimensionally; and all the offsets are set on the CMM so there’s no setting on the machine.”

The Merge software collates all the programs, Zero Transfers, and information about the spark positioning. It works with up to 12 electrodes at a time, bringing all the CNC programs together and identifying the X, Y, Z and U orientation, putting everything together in a format that runs on the Sodick to the correct datum, automatically adjusts the tank height, and provides a setting sheet.

Merge is proving to be so beneficial for both simplifying and speeding up the work on the Sodick EDM that Kavia is now developing the software commercially for those machines. “It’s currently being trialled in the field, and we’re aiming to start marketing it shortly,” says Mark Cole.