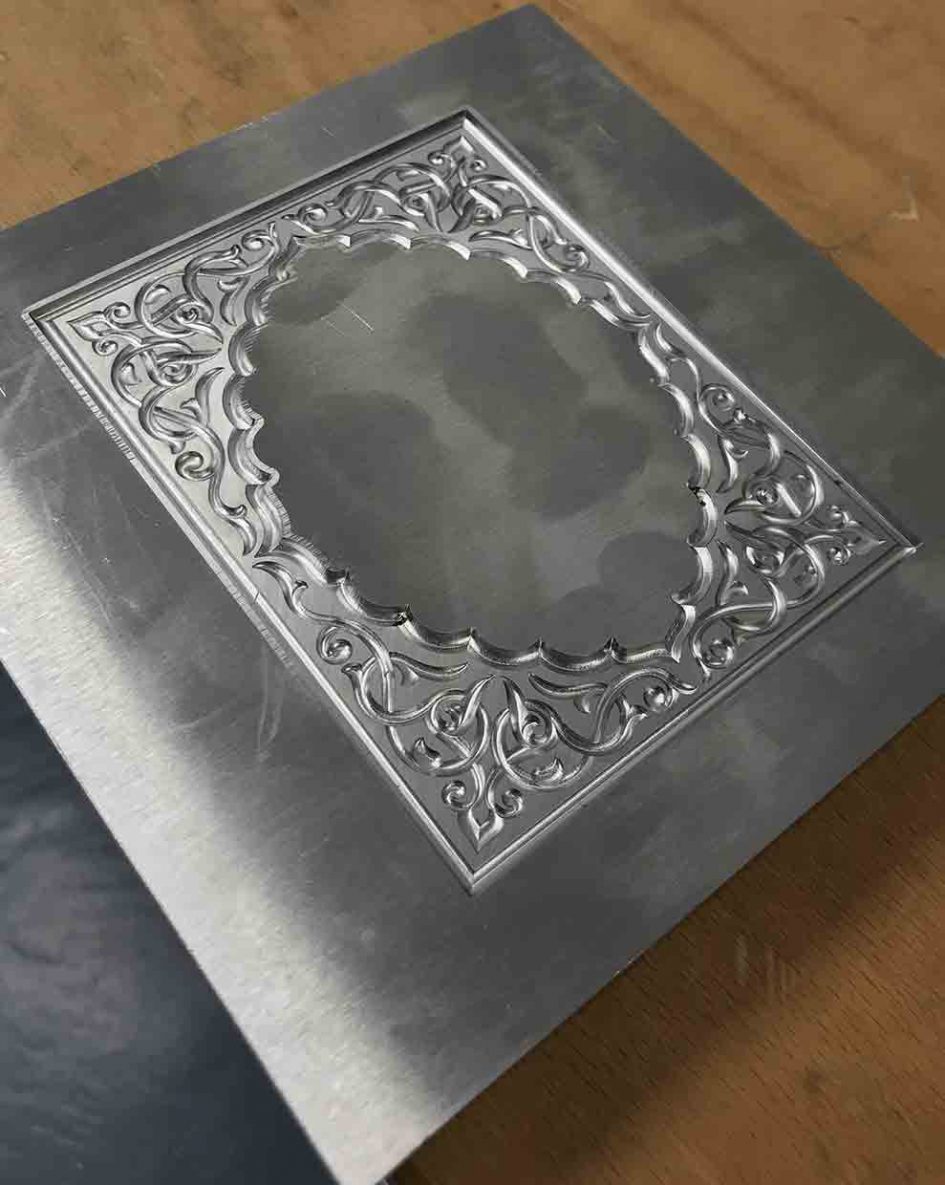

While a relative newcomer, in terms of business, having been founded in 2016, Techgrave has carved out a market-leading position thanks to its combination of machine tool technology and the decades of experience held by its founders Pete Adams and Dillon Evitts and their dedicated team. Techgrave provides bespoke industrial engraving and toolmaking to a diverse range of customers, but with particular focus on the manufacture of dies and punches for the production of collectable coins for mints around the world and military medals both new and reworking existing dies for long established awards such as the OBE, the jewellery sector is also a prominent user of Techgrave’s services. In order to deliver to the highest standards, it has invested heavily in CNC engraving, laser, reverse engineering, CAD/CAM and, most recently, its toolroom capabilities.

This latest investment saw the arrival of an XYZ MiniMill 560 HD vertical machining centre, an XYZ SLX355 ProTurn lathe, an XYZ KMX 1500 turret mill and an XYZ surface grinder from XYZ Machine Tools. This combination of machines provides a complete toolroom solution for Techgrave and, greater control over quality and delivery. “When we first started our initial investment went solely on engraving equipment and software, with any toolroom requirement being sub-contracted,” says Dillon Evitts. “As we got busier, we started to find delays and quality issues with outsourcing, so took the decision to bring toolmaking in-house. The XYZ machines give us total control over manufacture of die and press tool blanks, collars and die holders and the knowledge that we can guarantee 100 per cent conformity across our entire manufacturing process.”

While the initial requirement for the XYZ machines was to meet Techgrave’s in-house machining requirement in order to streamline its own manufacturing and enhance service to customers, their arrival quickly turned into a business opportunity. “When we budgeted for the machines, we were happy that producing our own work would cover their costs, so had no desire to fill any spare capacity, we were just happy that we had the capability to meet the demands of our customers. One day we might be making a die for a coin, the next might be a mould for a running shoe, it’s that varied. However, as word got out that we had this capability we began to receive inquiries from existing customers for toolroom work,” says Pete Adams. “We look on this work as a bonus but remain adamant that it will not impact on our own production, whether that is work for established customers in the minting sector or one-off commissions for jewellery and even vintage cars and motorcycles.”

One of Techgrave’s biggest issues is the variety of work it undertakes not only for its own production, but for that of customers asking for sub-contract machining capacity. It is here that the versatility of the XYZ machines is highlighted, particularly the control systems. The ease of use of the ProtoTRAK and Siemens controls makes them ideal for the quick turnround of one-off and low-volume production, with all programs for the lathe quickly and easily created at the ProtoTRAK control, while a combination of at-machine programming and offline programming is used for the Siemens controlled MiniMill 560. “It is here that the XYZ machines come into their own as we don’t know what is coming in from day to day,” says Dillon Evitts.

This additional work has also come about thanks to the relationship developed between Techgrave and XYZ Machine Tools, with the Birmingham-based company happy for potential XYZ customers to visit and see the machines in action. This openness leads to the potential of new work, which may only be short-term while a customer places an order for a new XYZ machine. That situation suits Dillon and Pete down to the ground. “Our philosophy with toolroom work that we take in for customers is that it may be a one-off or irregular work, but we are building relationships, this has proved a route to growth as customers respond positively to our service and attitude.”