- Prima Additive, the Prima Industrie Division dedicated to metal additive manufacturing systems, will be exhibiting at A&T Automation and Testing in Turin (Stand B59) from 12 to 14 February 2020.

- Prima Additive will present the Print Sharp 250 (build volume 250x250x300mm), its medium-volume machine for Powder Bed Fusion applications. The machine assures high-quality components in terms of surface and mechanical characteristics while it can offer post-processing solutions able to meet the most demanding targets.

- At Prima Additive booth it will be also showcased the Advanced Laser Head, an innovative multi-purpose DED laser head with a modular design that can be mounted in different configurations to easily adapt to multiple laser processes, and the new Convergent CS450 laser source, developed by Prima Electro for Additive Manufacturing.

Torino, 12-14 February – Prima Additive will be participating in the 14th edition of A&T Automation and Testing, the trade fair dedicated to innovation, technologies, and 4.0 skills that will take place in Torino from 12 to 14 February 2020.

The slogan “Add Something New”, that will characterize the Prima Additive stand for this exhibition, is an invitation to customers to unleash the potential of Additive Manufacturing solutions for their business. Leveraging on more than 40 years’ experience in 3D and 2D laser processing machinery, today the Prima Industrie group is also a competent partner for the 3D metal printing sector. Prima Additive products are designed to allow customers to exploit the competitive advantages of AM, thanks to their high productivity, first-rate process reliability, outstanding quality of finished parts, and excellent performance-price ratio.

At the exhibition, it will be showcased the Print Sharp 250, a medium-volume machine for Powder Bed Fusion applications. Designed to facilitate an efficient operation, Print Sharp 250 includes an intelligent control software and a user-friendly interface for an easy and efficient machine setup and operation. The simple operating and maintenance procedures increase the machines utilization rate and performance. Furthermore, the machine is equipped with an integrated glovebox and a plug-in for the vacuum cleaner, to allow the user to operate on the machine without being in contact with metal powder. With a building volume of 250x250x300mm, Print Sharp 250 assures high-quality components in terms of surface and mechanical characteristics while it can offer post-processing solutions able to meet the most demanding targets.

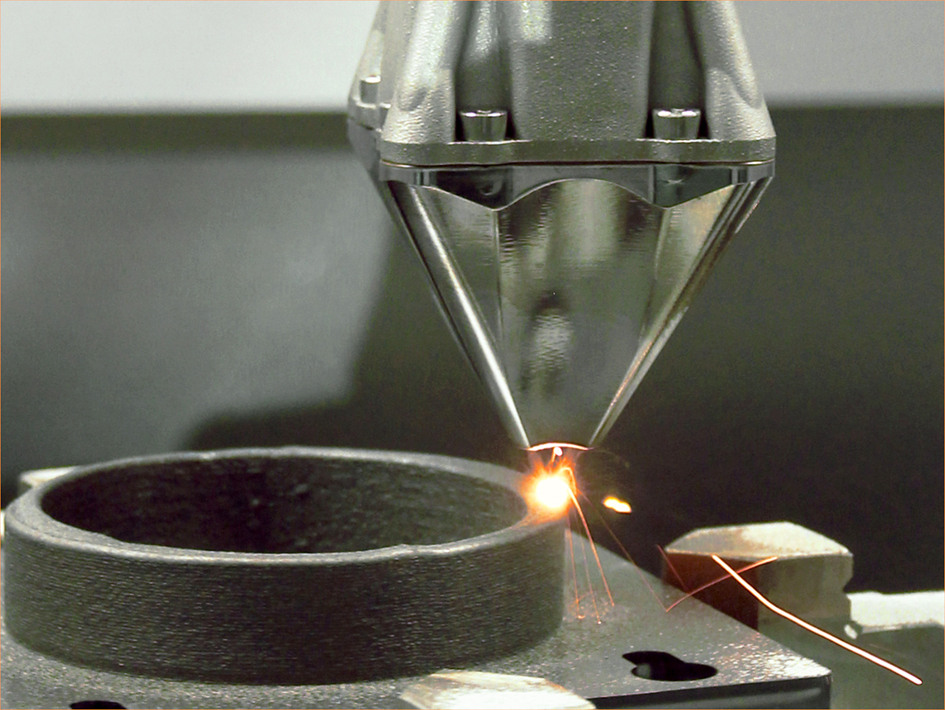

The new Prima Additive Advanced Head is suitable for a wide range of DED applications

Visitors will have the chance to see and to touch by hand some pieces produced with Prima Additive machines and to ask our experts more information on additive manufacturing solutions and the full range of services provided along with the systems. Besides the additive manufacturing systems, Prima Additive provides a full range of services, covering the entire life cycle of the system and technology. This contributes to maximising the added-value benefits and profit for our customers.

At the booth it will be also showcased the Advanced Head, an innovative multi-purpose DED laser head with a modular design that can be mounted in different configurations to easily adapt to multiple laser processes. Some of the strengths of the new head are fusion metal pool monitoring, pressurized optical path that avoids dust infiltration and a water-cooled nozzle for continuous deposition, which reduces the risk of powder adhesion during the process. The additive nozzle itself is manufactured using additive manufacturing processes. The head also offers easy maintenance and fast alignment of the powder to the laser spot. The Advanced Head can be mounted on all Prima Industrie Laser Metal Deposition products, and is also available as part of Prima Additive’s Laser Metal Deposition Kit, which includes the head, a high-efficiency laser source, a flexible powder feeder and additive CAM software for off-line programming. The kit can be integrated into nearly any laser machinery and robotic system.

The new Convergent CS450 laser source, developed by Prima Electro, will be also exhibited on the Prima Additive stand. This is a highly efficient and compact fiber laser for Additive Manufacturing, developed with the laser technologies expertise of the Prima Industrie Group. The main benefits of this laser source are a high beam quality, high efficiency (up to 30% wall-plug efficiency), simple, compact, robust and maintenance free design, with long term power stability.

We look forward to welcoming you at our stand! Visit us at A&T, from 12 to 14 February,