A new range of press brakes has been introduced by Bystronic designed so that they can be customised to suit a user’s requirements in terms of process speed and flexibility. Available in the UK and Ireland through the Swiss manufacturer’s Coventry subsidiary, the modular Xpert Pro series comprises three models plus a variety of optional extras.

The Classic Edition is intended for prototype manufacture and job shops producing small batch sizes. With the Performance Edition, medium-sized companies can produce larger series quickly and reliably. Dynamic Edition is ideal for companies that need even more speed to handle batch sizes of 1,000 pieces or more efficiently. It is claimed to be one of the fastest press brakes on the market, with bend speeds up to 20 mm/sec.

Press capacity ranges from 100 to 320 tons, enabling sheet up to a thickness of 15 mm to be processed; and bending length is either three or four metres. Companies that require even more flexibility can connect two machines together to bend longer parts.

Thanks to the variety of configuration options, application possibilities are extensive and an Xpert Pro can be flexibly adapted to new requirements through straightforward retrofitting of optional modules. For example, if at some point a company wants to bend complex shapes in addition to rectangular parts, they can retrofit a backgauge with from two to six CNC axes.

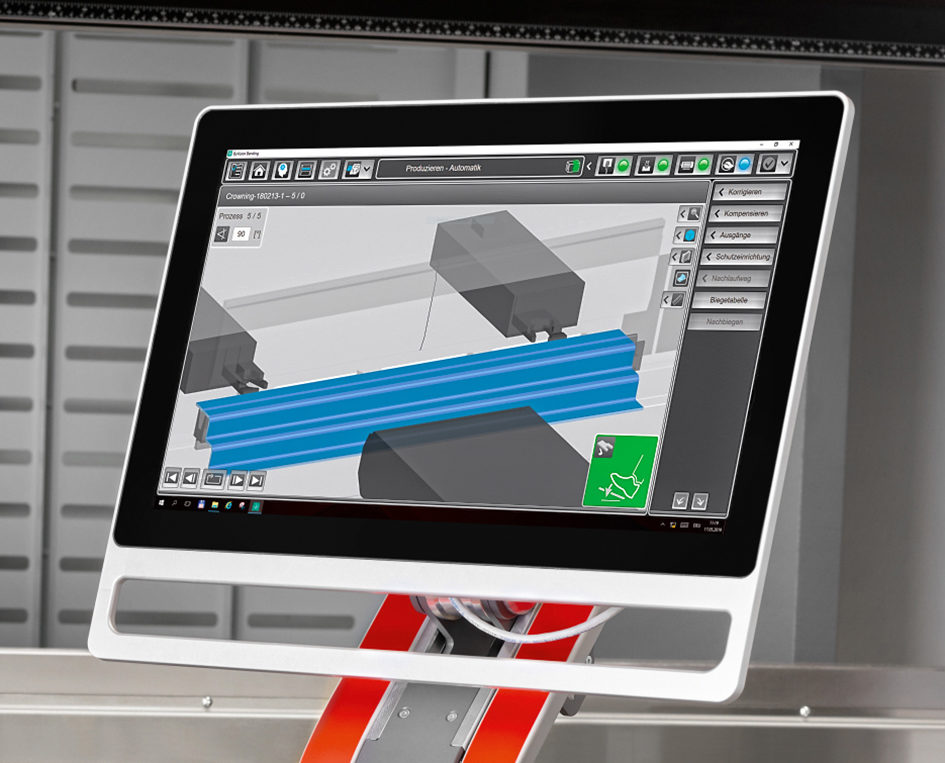

A model from the new Xpert Pro press brake range from Bystronic.

Manufacturers that have already invested money in bending tools want to reuse them when they purchase a new press brake, but this usually not possible when changing supplier as there are almost a dozen different tool systems on the market that are incompatible with each other. This problem has been solved by the Xpert Pro range, as the versatile machines have been designed so that tool systems from other suppliers can be used. An automatic toolchanger is available as an option for even more efficient changeover between jobs.

Bystronic’s patented dynamic crowning compensation system ensures bend accuracy and consistency by automatically adjusting the curvature of the beam during the bending process. The latest generation of pressure reference technology carries out corrections in real time based on closed-loop feedback from sensors.

For even higher process reliability and repeatability, an angle measuring system called LAMS is available as an option to compensate for springback and deviations in the thickness of the sheet being bent, which can be as much as 10 per cent. Correction data for that particular material can be stored and transferred to other machines, even those not equipped with LAMS, to avoid tedious manual corrections.

ByVision Bending software determines the ideal process for every material thickness and bend angle. Convenient offline programming enables data to be imported without interrupting production.