KASTO has comprehensively re-engineered its ‘tec’ range of top-end, horizontal bandsaws, which are intended principally for automatic, high performance processing of all materials including difficult-to-cut metals using carbide saw blades. New features have been incorporated enabling faster production, allowing cutting cycles to be halved in some cases. At the same time, tool wear is reduced.

The benefits are largely a result of the incorporation of a pair of servo motor-driven ballscrews for steplessly adjusting the downfeed to optimise the management of bandsaw blade chip load. The system is combined with the integration of KASTOrespond technology, originally developed by the German manufacturer for its ‘win’ bandsaw range, for continuously monitoring the pressure on the blade so that the downfeed force can be optimised, irrespective of whether solid material, tube or profile is being cut.

The saw feed control, without the need for additional and often error-prone sensors, enables cutting parameters to be continuously adjusted, not only at blade entry and exit but also throughout the entire cut. By constantly detecting the changing engagement length when processing round stock and also sensing hard spots in any material, KASTOrespond converts the measured forces on the tool into digital signals for adapting the downfeed speed.

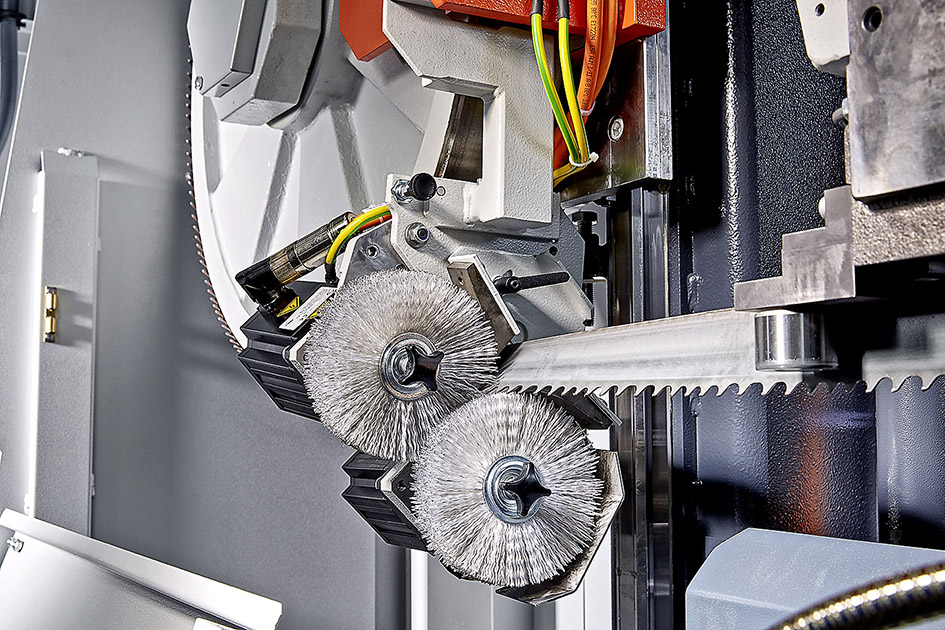

The double brushes that clean the blade on new KASTOtec saws are always optimally positioned for efficient chip clearance.

The user needs only to enter data such as cut lengths and number of pieces, together with the type of material to be sawn and its diameter, directly at the proprietary KASTO ProControl with colour touch screen interface. Everything else is taken care of automatically.

There is an additional, environmental benefit of electrically actuated ballscrew feed, as only a much smaller, separate hydraulic unit is required for stock positioning and clamping, so there is a significant reduction in the amount of power needed to run these new machine tools.

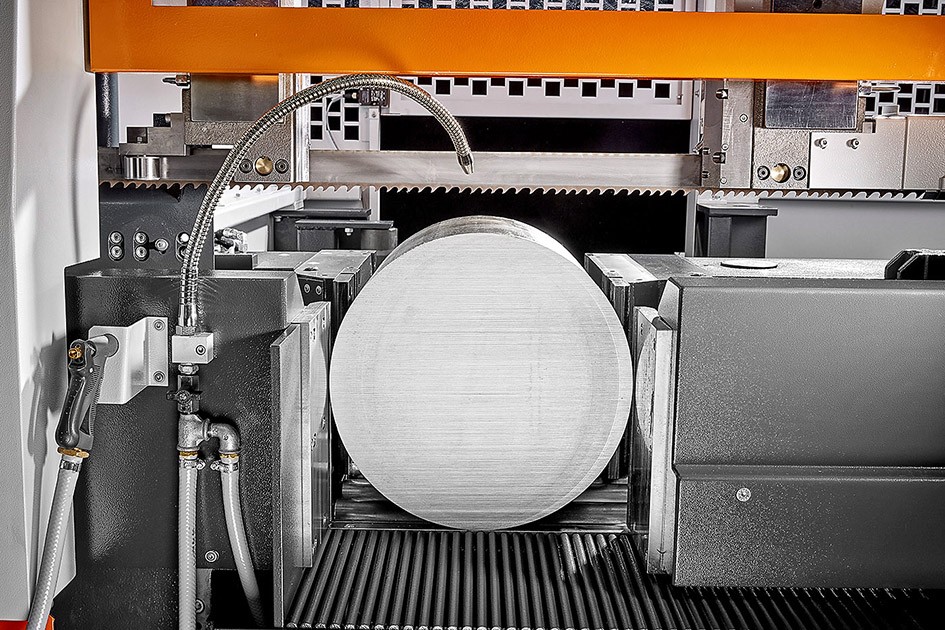

The second-generation KASTOtec machines will be presented for the first time in the UK at MACH 2020 on the stand of the firm’s Milton Keynes subsidiary. Demonstrated under power will be an AC5 model, which is capable of cutting stock up to 530 mm in diameter or bundle cutting up to 530 x 630 mm.

The latest generation of KASTOtec saws continuously monitors the downfeed force on the band to optimise the sawing process.

As with the earlier machine range, a steel and mineral cast baseframe delivers efficient damping and quiet running, even when cutting materials such as titanium, Hastelloy and Inconel. Vibration – the main source of sawing inaccuracy and machine wear – is lowered further by spring-loaded tensioner guides inside the top of the saw head guarding that provide the band with extra support.

New is a frequency-controlled bandsaw blade drive through a bevel spur gear that exploits the advantages of both gear types, delivering 15 kW of power and infinitely adjustable cutting speeds from 30 to 300 m/min. Pre-tensioned linear guides, each with two grease-lubricated carriages, also help to extend the working life of the machine.

The manufacturer has even gone to the trouble of including a system for automatically optimising the position of a pair of cleaning brushes relative to the band so that chips are always removed optimally from the saw teeth, preventing recutting and consequent tool wear and damage.

LARGER BANDSAW FOR THE WORKSHOP

The KASTOmicut range of pivot-bow, metalcutting bandsaws from KASTO has been extended upwards and downwards from the three pre-existing, automatic and manually operated 2.6 models that were launched at MACH 2018.

The new KASTOmicut U 4.6, which will be exhibited at MACH 2020 for the first time in the UK, can saw flats up to 520 mm wide at 90 degrees and mitres from -45 to +60 degrees. Material clamping is effected by a horizontally acting, hydraulic vice. Band speed range is wide at from 12 to 150 m/min for processing an extensive range of different materials cost-effectively.

The new KASTOmicut U 4.6 pivot-bow, double mitring bandsaw will make its first appearance in the UK at MACH 2020.

A heavy, torsionally rigid, welded saw frame provides stable support for the blade and allows high band tension, ensuring a good quality cut even with hard-to-machine materials. Various accessories are available including a rotary table to support the material.

Included in the range of larger machines is KASTOmicut E 4.6, which has the capacity to cut 335 mm diameter round and 460 x 335 mm flat material. It is designed for single-sided mitring at any angle from 0 to +60 degrees.

For users who mainly saw smaller workpieces up to 180 mm diameter, KASTO has introduced the compact KASTOmicut P 1.8 capable of mitring between 0 and +45 degrees. Downfeed rate is determined by manually guiding the saw frame and the blade is driven by a 1.5 kW three-phase motor, ensuring high quality cutting.

Depending on machine model, the shortest cutting length is between 6 and 10 mm. With a remnant length of 15 to 30 mm, users can make maximum use of the material being sawn. An efficient worm gear drive provides top performance and the advanced design ensures a constant cutting force for efficient processing of different materials.

As a large percentage of the parts used in the various bandsaw models is identical, KASTO is able to offer them at attractive prices. An extensive variety of accessories is available to extend the application of all the saws.