The latest version of PSL Datatrack production control software is now available. 227 Wishlist ideas have been satisfied in this release, adding 131 new configuration options which now total in excess of 1300. The update is focussed on improved automation, ease/speed of use and management control, with scheduling efficiency and reporting also enhanced.

Many of the software’s additions are based upon the company’s Wishlist programme, through which customers submit new ideas and PSL consider these for future releases. Various PSL Datatrack original concepts are also encompassed in this version. “The strong focus that PSL Datatrack has on the subcontract precision engineering industry is a result of the close contact we have with our customer base,” comments Geoff Gartland, Managing Director.

Many Wishlist ideas, taken on board in the new release, focus on automation. Invoices can now be emailed straight from the system, reducing administration time as there is no longer a need to type emails and manually attach invoice documents. The system has also seen a Works Order Generator added, which greatly reduces the time taken to raise multiple works orders from a single customer purchase order. There are further time savings when raising delivery notes on the system, as carriage can now be added automatically, and when raising purchase orders for Bills of Material (BOMs) as users are now able to add multiple lines at once.

PSL has also tightened management control within the system. A new ‘pending’ works order status is incorporated, effectively working as a contract review so that supervisors/management must approve and release a job before it can begin. In Shop Floor Data Collection (SFDC), users can now record the quantity of components produced and/or scrapped during setting. This is particularly useful for smaller batch runs where the cycle time is significant, ensuring an accurate comparison to scheduled time.

With tight control in mind, the Scheduler module has seen a number of enhancements. Additional works order quantities can be added, with the Scheduler (and material requirements) automatically increased to cater for the extras. Grouped scheduling is an impressive new feature to reduce setting time for similar components. Operation efficiency can now reflect the reality of lights out running.

PSL Datatrack’s reporting capabilities have been extended to cater for the above additions, as well as numerous others. New reports are also available, including an outstanding works order report which shows an annual value view and total figures in sterling with percentage splits. A new tree navigation screen allows relevant users to clearly navigate through assembly quotations and works orders.

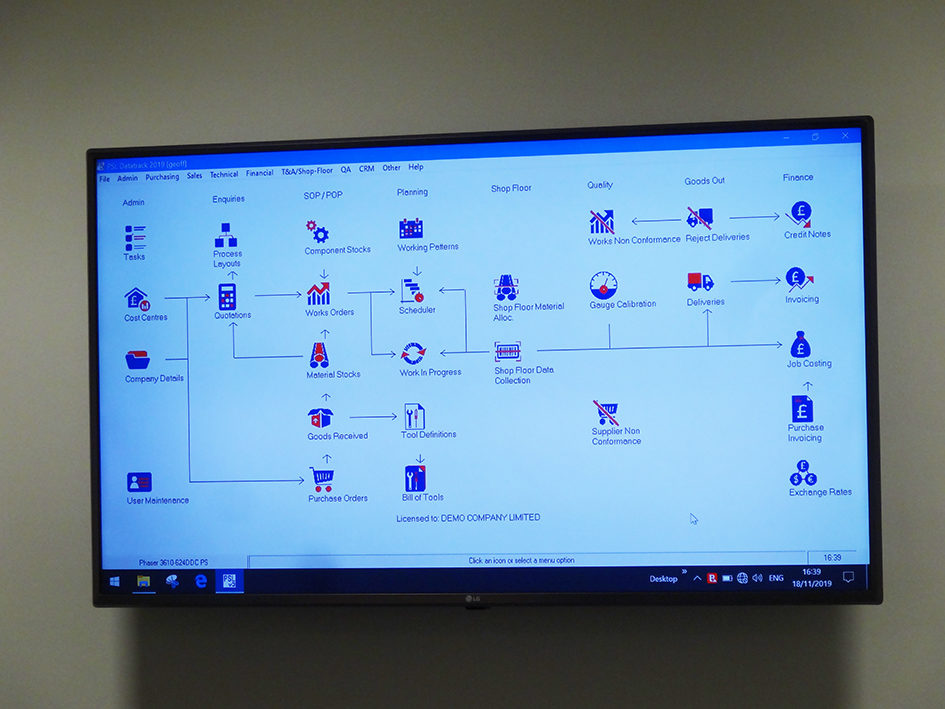

The development team has worked hard to display valuable data in a clear, concise and user-friendly way. New desktop/dashboard options can present 57 Key Performance Indicators (KPIs) for quick reference to users with relevant permissions or the desktop can be switched to a new visual Roadmap, beneficial for newer users to become familiar with the information flow throughout the system.

For purchasers, instant supplier quality information is now revealed when selecting an account for a purchase order. This shows the total and outstanding number of Supplier Non Conformances (SNCs) as well as the early, on time or late delivery performance over an agreed period.

The new release has been well received by existing PSL Datatrack customers. New customers installing the system over the coming months will automatically see this version installed and implemented.

“With over 30 years of supplying production control systems, every new version has focussed on constant improvement whilst maintaining ease of use with practical, simple and logical screens and this version is testament to that approach,” concludes Geoff Gartland.

For more information, visit www.psldatatrack.com or contact PSL Datatrack, Lily Hill House, Lily Hill Road, Bracknell, Berkshire, RG12 2SJ, Tel: +44 (0) 8456 345931, Email:sales@psldatatrack.com