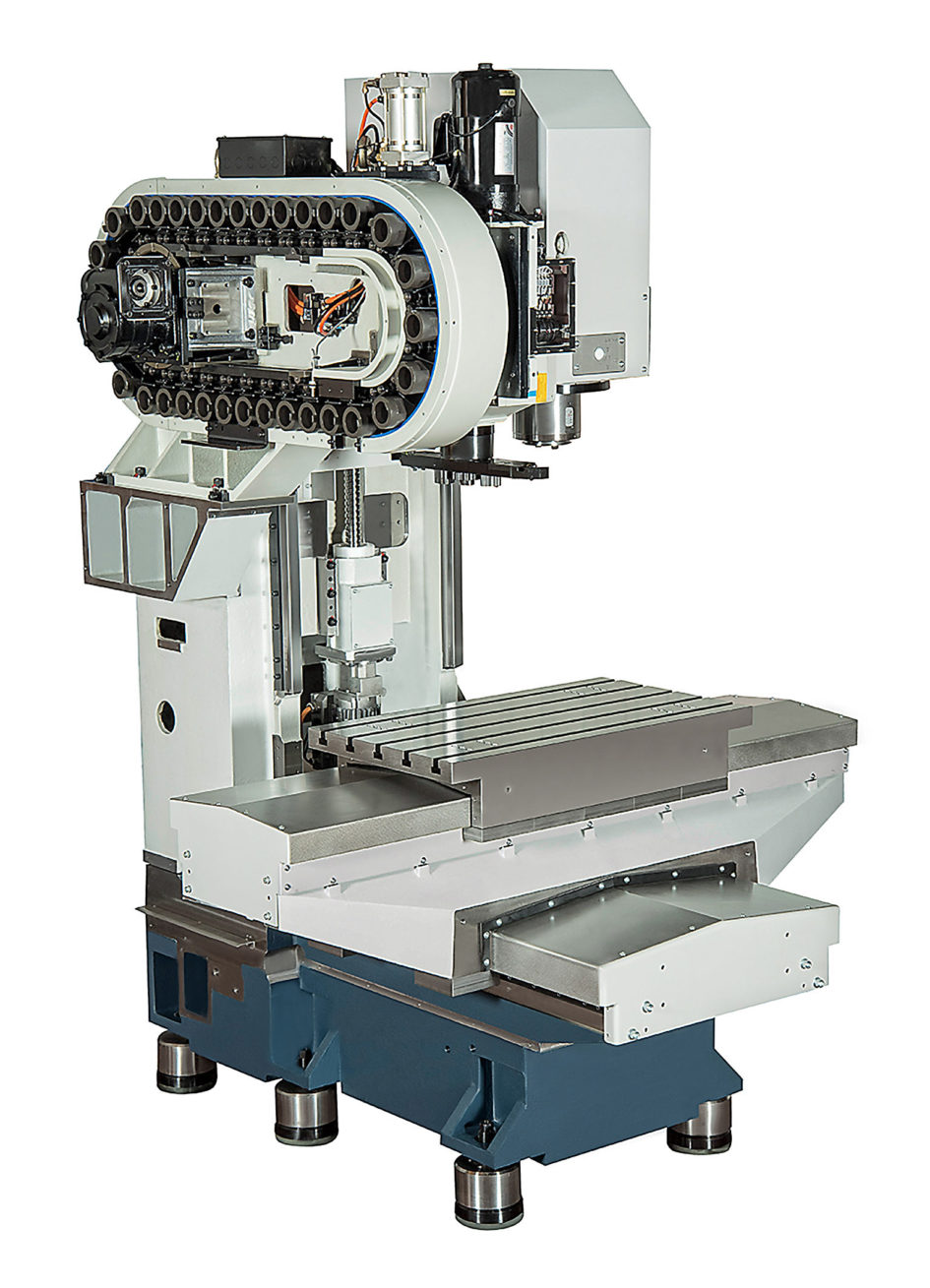

German machine tool builder Spinner has introduced a new, vertical-spindle, 3-axis machining centre with a generous working volume of 850 x 510 x 510 mm and a small footprint of 1.8 x 1.85 metres. The impressive ratio is achieved by adopting a patented method for protecting the saddle’s Y-axis guideway from swarf and coolant ingress using a single wiper system, eliminating the need for a telescopic cover. The depth of the machine is consequently shorter, leading to a 30 per cent reduction in the area needed for installation.

The machine is available in the UK through sole sales and service agent Whitehouse Machine Tools, Kenilworth (www.wmtcnc.com), which points out three other notable attributes of the Spinner VC850. One is that the height with the spindle when raised to its maximum is just over 2.4 metres, catering to users that have restricted headroom in their factory. A transport height of 2.3 meters without significant disassembly helps access to buildings.

The second feature is that the X-axis guideway also has a single wiper for protection, allowing the table to move to the extremes, so automated loading and unloading from the sides is simplified. Thirdly, a short distance of 160 mm from table to operator leads to ergonomic use that is assisted further by a height-adjustable, swivelling control panel. The latest generation Siemens 840D sl CNC with 24-inch touch screen is fitted, while availability of the Heidenhain TNC640 control is imminent.

The Spinner VC850 with guards removed, showing the patented method of protecting the X-axis and Y-axis guideways from ingress of swarf and coolant using a single wiper system rather than a telescopic cover

The machine has an FEM-optimised, cast construction that provides a high level of rigidity and vibration damping for elevated cutting performance and high standards of surface finish on machined components. Further advantages are that tool life is extended and accuracy of machining is enhanced. Rapid traverse and maximum cutting feed rate are 40 m/min, contributing to high productivity, and table load is up to half a tonne.

Often overlooked when drawing up a machine tool shortlist is the aspect of chip disposal. Spinner has optimised efficiency in this area by providing a pair of spiral augers to deliver chips to a conveyor at the front of the machine for convenient removal.

There are two variants of powerful spindle, a high-torque 12,000 rpm / 18.2 kW SK40 or BT40 version as standard or optionally an HSK63 alternative offering 18,000 rpm / 18 kW. Either 32 or 48 pockets in the tool magazine may be specified. Other options include mist extraction, a rotary table to provide a fourth CNC axis, linear scales in place of rotary encoders, 22 bar or 70 bar high pressure coolant delivery, workpiece and cutter measurement and tooling packages.