The recent EMO exhibition in Hannover proved a resounding success for Ward CNC, as the machine tool specialist used the European machine tool show to introduce customers to the latest innovations from its machine tool partners.

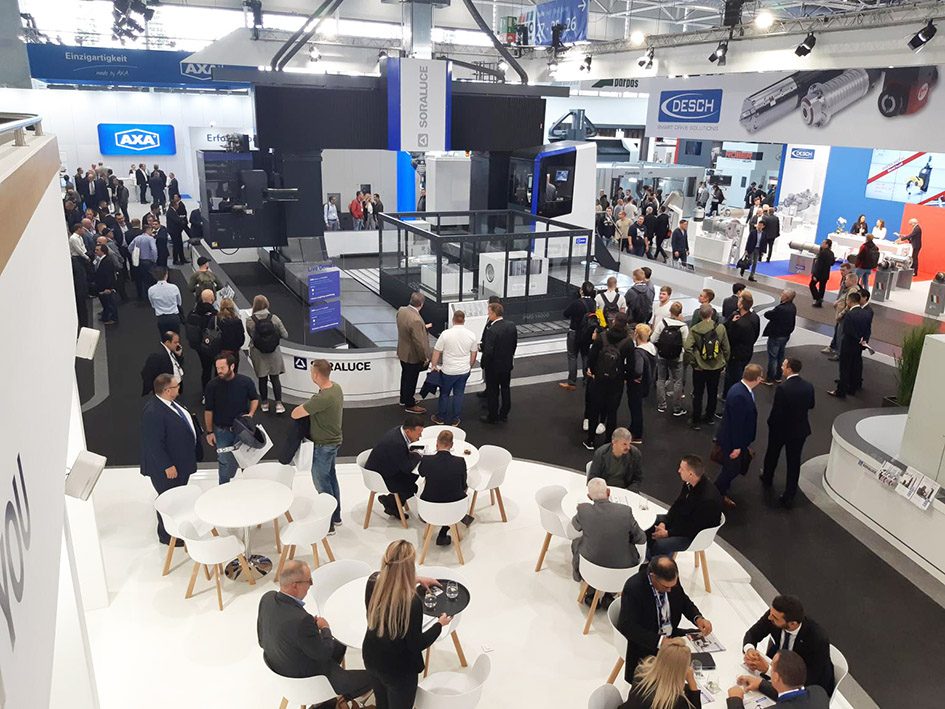

Exclusively representing brands such as Axile, Hankook, Hartford, Hyundai-Wia, Pinacho, Soraluce, Takisawa Japan and Takisawa Taiwan in the UK, each of these exciting brands introduced a plethora of new technology at the EMO show. To absorb the overwhelming launch of new innovations, members of Ward CNC’s Management Team attended EMO to gather the latest information and insights from the respective partners. Simon Whitworth, Managing Director; Stephen Bodsworth, Executive Director and Stuart Lawson, the Head of Strategic Accounts & Projects were all at the event to discuss opportunities with UK engineers and the feedback was extremely positive.

On the Hyundai-Wia stand at EMO, Stephen Bodsworth was more than enthused by the technology that will soon be available in the UK and ROI from Ward CNC. The Hyundai-Wia booth had no fewer than 10 machine tools with multi-tasking and Y-axis turning centres, a selection of 3 and 5-axis machining centres and a horizontal machining centre with automation, HS6300+ PLS (Pallet Load System). Commenting on the booth, Mr Bodsworth said: “Hyundai-Wia is one of the worlds most recognised brands and the focus of this stand is not only the new machine tool innovations, but as importantly the new Hyundai-Wia ‘Smart System’ software and equipment monitoring software. The slogan on the stand is ‘Experience the New Technology’ and upon our return to the UK, Ward CNC will be introducing the new Industry 4.0 platforms and their benefits to UK manufacturers.”

Equally impressive was the Soraluce stand and its multitude of new technologies that included the DAS+® Dynamic Active Stability (elimination of chatter during machining) system that maximises chip removal capacity during machining. Another highlight was the DWS Dynamics Workpiece Stability (elimination of workpiece vibration during machining) system, a portable component mounted unit to remove chatter from fabricated/non-rigid workpieces. Further innovations included a new 5-axis (continuous) milling head and the VSET system, a patented clamping system to provide time savings for simplified off-machine set-up and alignment.

Further innovations included the Ram Balance system that improves ram geometrical accuracy, straightness and parallelism when vertical and cross axes are moved – increasing general precision of the machine. Also well received at the show was the DHC Dynamic Head Calibration system, a self-calibration concept that improves the accuracy of the compensation parameters associated to the head. Soraluce demonstrated for the first time, grinding on a TR-M35 machining centre at EMO, the technology advancements will be available in the UK in coming months.

Looking toward the machining of everything from the larger components to the smaller prismatic parts, Hartford also had a plethora of new products at EMO whilst a specific focus on 5-axis machining and Industry 4.0 was the core focus of the Axile booth. Automated production with zero downtime and the integration of Industry 4.0 technology was evident on Axile machines with the ART system drawing the crowds at the show.

For the production of smaller turned parts that demand the utmost in productivity and precision, Takisawa had two stands at EMO. With an unfathomable wealth of new machine tool technologies and software platforms being introduced at the show, please contact Ward CNC to understand how your productivity, processes and manufacturing platforms can be transformed.