Prima Power cutting edge solutions covering all stages of sheet metal processing will be on show at the upcoming Blechexpo:

- the servo-electric press brake with automatic tool change storage eP Genius 1030, making its worldwide debut;

- the 2D machine Laser Genius 1530 with 10 kW fiber laser and flexible storage system Combo Tower Laser;

- the integrated punch-laser system Combi Genius 1530 with LSR Loading and Stacking Robot;

- the servo-electric BCe Smart bending cell with new API (Advanced Profile Inspection) and DABA (Dynamic Adjustment of the Bending Angle) technologies.

Laser Genius 1530 fiber laser machine with 10 kW laser and Combo Tower Laser by Prima Power

“Prima is here” epitomizes Prima Power approach to customers, not only during the exhibition, but in every moment of contact with them. Prima Power is always at its customer’s side to offer support and expertise with its advanced technologies, truly listening their needs and giving cutting-edge and human-friendly solutions to their requirements.

Making its world premiere at Blechexpo will be Prima Power’s new bending solution, the eP Genius 1030, consisting in the integration of a servo-electric press brake eP-1030 with an automatic tool change storage. The highly dynamic, accurate, and reliable servo-electric technology, granting constant performance over time thanks to the absence of hydraulic oil, combines with the benefits of a fast and dynamic automatic tool change system. The result is a more versatile, faster and more reliable bending system, which eliminates the manual set-up of the machine and allows the operator to commit his time and skills to the preparation of the bending batches. This solution is specially fit for minimum batches, where it is possible to reliably estimate the machine set-up, and short cycle times become imperative to gain a higher market competitiveness.

The eP Genius press brake has 15 axes and a maximum tool capacity up to 32 meters. The eP-1030 press brake included in the solution is the most versatile machine in the eP servo-electric range, a perfect combination of tonnage and work capacity (105 tons with a bending length of 3060 mm), automatic CNC crowning, 5-axis back gauge and IRIS Plus angle control system on CNC-controlled motorized arms. The tool storage, which is the main innovation of this product, can accommodate a total of 32 meters of tools to be placed on 8 tool holder supports that move on 3 axes. It allows to handle tools (Wila style) with a minimum length of 20 mm up to 515 mm. Furthermore, a rotating turret rotates the tools taken from the storage to grant multiple processing possibilities. The latest-gen user interface allows the programming of the piece in a simple and intuitive way, both on the machine and off-line, as well as the automatic management of the machine set-up.

In Stuttgart Prima Power will display the high performance Laser Genius 1530 fiber laser machine with 10 kW laser, featuring best-in-class piercing time of less than 1 sec, and new cutting nozzles granting a reduction of gas consumptions. These benefits add to a highly productive and accurate machine boasting linear motors, carbon fiber carriage and intelligent process sensors. Laser Genius with 10 kW fiber generator is the ideal solution for all industrial fields: from subcontracting, as well as agricultural & construction machinery, up to industrial vehicles.

The machine is showcased with Prima Power flexible storage system integrating loading and unloading features Combo Tower Laser, the optimal solution for lights-out production with its large capacity of raw material and its intermediate storage for ready cut components along with skeletons. Laser Genius grows with customer’s needs and it can be integrated at later stages with other modules, such as the automatic sorting system LST, to enhance the automation level of the production flow within the factory.

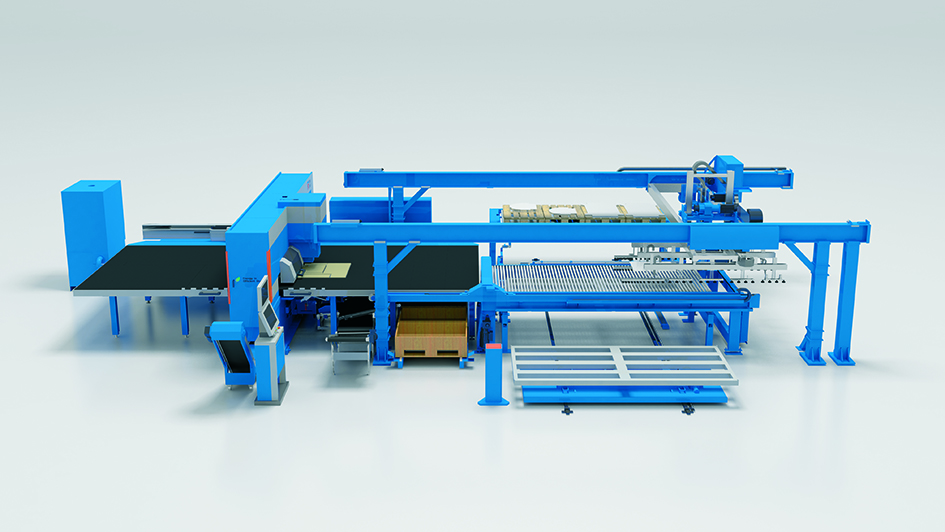

Combi Genius with LSR

This year Prima Power celebrates 30 years of integrated laser-punch technology. At Blechexpo the ultimate result of this impressive experience will be showcased: the Combi Genius 1530 with the new eye safety protection mounted around the cutting head, which avoids the use of protective walls around the machine, resulting in greater accessibility and visibility of the system and simplified installation.

Combi Genius is available in two different performance categories: Pure, for an efficient production with a lower level of investment, and Dynamic, displayed at the exhibition, for maximum productivity and efficiency. The turret of the Combi Genius can be customized and optimized for any requirement. Simultaneously, a record-breaking number of 384 tools can be inserted in the turret. Combi Genius features the Intelligent Ram, which shortens tool change time and increases the number of tools in turret, especially index tools, and can be equipped with Multi-Tool® stations to further increase the number of tools. Up to 300 kN servo-electric punching force can be selected for the ram. The machine is equipped with CF series 4 kW fiber laser, developed and manufactured by Prima Power, and the LSR Loading and Stacking Robot for the automatic material handling up to stacking of workpieces onto pallets.

Prima Power will also exhibit at the Blechexpo 2019 the well-known servo-electric technology of BCe Smart bending cell. It is a servo-electric semi-automatic machine, ideal for single piece production, kit of components, perforated material, sheets with big holes and embosses. Its compact layout and combined loading and unloading sequence guarantee high productivity. The machine is designed for customers looking for a flexible and semi-automatic panel bender with a “safety integrated” concept that allows the operator to focus only on value-added operations, aided by visual devices and sound signals.

BCe Smart comes equipped with two brand-new technologies such as API, Advanced Profile Inspection, which consist of a camera device used to apply corrections to a bend in order to reach the target angle within the required tolerance, and the revolutionary DABA technology (Dynamic Adjustment of the Bending Angle), thanks to which corrective parameters are proposed in relation to the material variables that allow a considerable reduction in the time required to create a new panel.

The software plays a fundamental role in the range of Prima Power products, as it allows the connectivity and the data exchange that are at the base of the digital transformation of the production and efficiently manages all the possible combinations among the different technologies. In the area dedicated to software visitors will be able to watch demonstrations of the new parametric functions of MasterBend, the new UI for Tulus Performance Reporting, and the new cloud-based application Tulus Analytics, which offers customers a variety of analyses derived from machine data.

The advanced technologies displayed on the Prima Power stand cover all main sheet metal working processes and its dedicated sales and technical team will be on hand to discuss the needs of the sector providing support, advice, and solutions for any business challenge and production requirement customers may have.