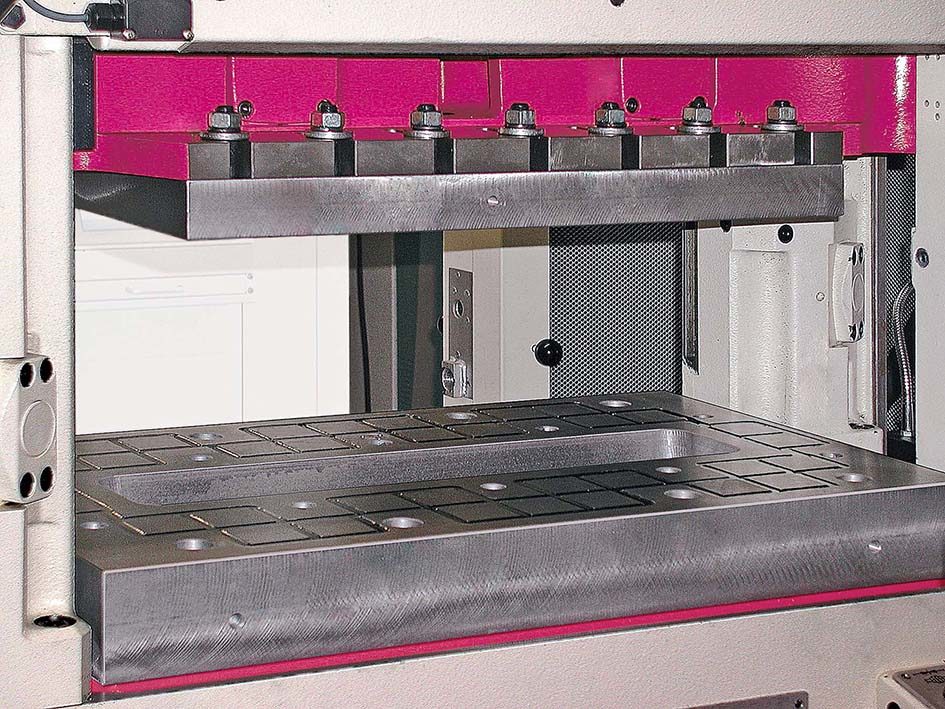

For automatically clamping dies on a press ram, Roemheld will show for the first time, on stand 8507 in hall 8, a system that uses integrated sensors to measure real-time data on holding forces and transmit the information to the machine control. The new Flexline rapid clamping system is therefore suitable for predictive maintenance and use in Industry 4.0 applications.

The operator has access to information concerning the actual clamping force on the die and is immediately able to detect overloads, the occurrence of unusual forces during operation, and die wear and breakage. The system facilitates error analysis and enables rapid problem-solving when servicing is required.

Due to the availability of a wide range of configuration options, Flexline can be used on almost all press models and for every die. It is suitable for either factory installation or retrofitting.

For reducing set-up times in sheet metal forming, Roemheld will also provide an overview of its ergonomic products for efficient, fast and safe transportation and change of heavy dies. On display will be four transport carts with different load-carrying capacities up to 1,600 kg; hanging and swivelling carrying consoles that facilitate insertion of a die into a press; and economical, freely configurable ball and roller bars to allow dies to glide easily over tables and other surfaces for effortless positioning.

Various Roemheld components such as magnetic clamping plates, locking cylinders, carrying consoles and roller bars will be demonstrated on a TOP Line 2000 press from automatic stamping and metal forming press manufacturer, Andritz Kaiser, on stand 8301 in the same hall.

Efficient clamping technology solutions for workpieces, as well as for dies in forming technology and plastics processing, form the core of Roemheld’s ever-increasing portfolio of products. In evidence will be some of the group’s hydraulic, mechanical, electro-mechanical and magnetic clamping elements. These are supplemented by components and systems for assembly and handling, drives technology and automation, and locking mechanisms for rotors on wind turbines.

In addition to having a constantly growing range of more than 30,000 catalogue items, the owner-managed group specialises in the development and realisation of customised solutions.