Auto Manufacturer Casts Success With MAPAL

As internationally acclaimed aluminium die cast business located in Mid Wales, Castalum was founded in 2000 and is currently one of the largest die casting companies in the UK. The company has two processes, high pressure die casting up to 2300 tonnes and squeeze casting, claiming to be one of the few substantial squeeze cast manufacturers in Europe. Cost per part and tool management is a critical factor for the company – that is why it relies on MAPAL.

Peter Radcliffe, Chairman of the Board at Castalum says: “We predominantly work in the automotive industry, as we are set-up for high volume production and we operate six days a week and 24 hours a day. We need to make a lot of castings to make the tooling cost viable and economic for the customer. We buy all of our metal filtered from UK suppliers and we make no changes to the materials with exception of a few small die casting additives.”

Peter Radcliffe, Chairman of the Board at Castalum says: “We predominantly work in the automotive industry, as we are set-up for high volume production and we operate six days a week and 24 hours a day. We need to make a lot of castings to make the tooling cost viable and economic for the customer. We buy all of our metal filtered from UK suppliers and we make no changes to the materials with exception of a few small die casting additives.”

Based in a primarily farming area in Welshpool, the company prides itself on its apprenticeship program. As Mr Radcliffe says: “When we came to the area, we came with 27 people that were a group we had largely retained from the expanding and skilful world of die casting. We constantly take on apprentices and employ up to four apprentices every year. With the local area being mainly farmers, these people have a great set of base skills and are great people to work with.”

Referring to the relationship with MAPAL, Mr Radcliffe says: “We went into machining absolutely from scratch. We had no background and we thought we had decent latent skills in machining and we knew that MAPAL were a good option in terms of the quality and what they can supply in terms of both their advice and their tooling. So, we immediately chose them as a partner and it’s something we’ve never regretted. We have developed the partnership on an ongoing basis. Right now, MAPAL don’t only supply us the tooling, prompt us on supply, maintenance and stocking matters; they also provide concurrent engineering advice for practically every RFQ that passes through the company.”

“The MAPAL relationship is firmly embedded in our business and our customers quite rightly expect us to have a full understanding of what we are going to be doing further down the line with regards to the work they are offering us. To have a company like MAPAL on-board that can give us objective and clear advice on what is possible is a real bonus,” continues Mr Radcliffe.

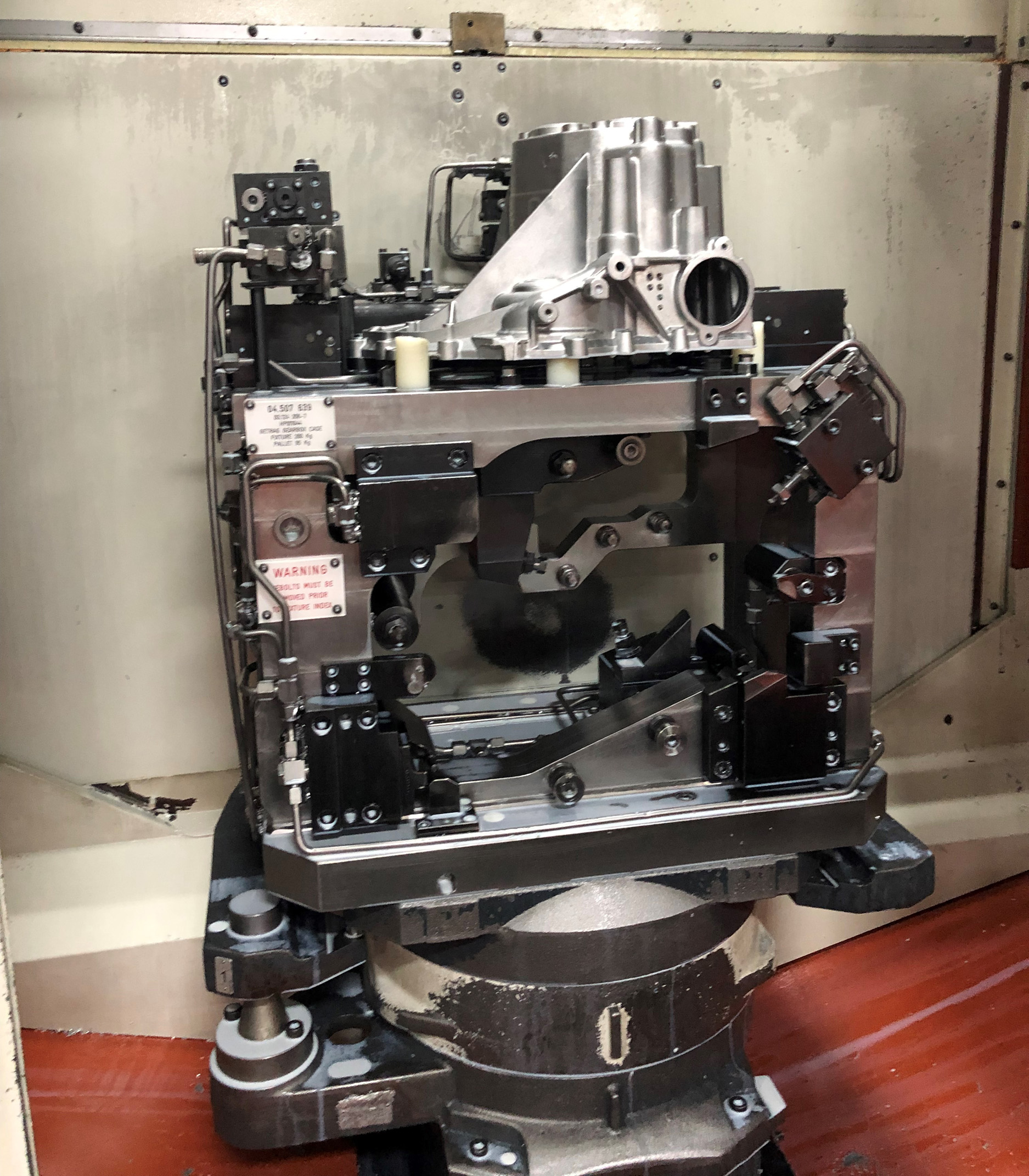

Discussing the partnership from a MAPAL perspective, MAPAL’s Ted Coyle says: “When I first became involved with Castalum many years ago, they were only involved in castings for the automotive industry. They then diversified into machining as many customers were asking them to do the machining as well as the castings. They got involved with Heller Machine Tools and their first involvement was a turnkey project. Heller work exclusively on tooling for casting projects like those undertaken at Castalum with MAPAL on the PCD tooling. We did the tooling on those initial projects and Castalum were then interested in approaching projects on a ‘cost-per-piece’ basis. MAPAL are a market leader on custom tooling on a ‘cost-per-piece’ basis. So, we came up with an offer to do components on this basis. The first work was the Trag 6 piece clutch housing. That worked very well and from there on in, we then started doing every project that Castalum brought in.”

Discussing the partnership from a MAPAL perspective, MAPAL’s Ted Coyle says: “When I first became involved with Castalum many years ago, they were only involved in castings for the automotive industry. They then diversified into machining as many customers were asking them to do the machining as well as the castings. They got involved with Heller Machine Tools and their first involvement was a turnkey project. Heller work exclusively on tooling for casting projects like those undertaken at Castalum with MAPAL on the PCD tooling. We did the tooling on those initial projects and Castalum were then interested in approaching projects on a ‘cost-per-piece’ basis. MAPAL are a market leader on custom tooling on a ‘cost-per-piece’ basis. So, we came up with an offer to do components on this basis. The first work was the Trag 6 piece clutch housing. That worked very well and from there on in, we then started doing every project that Castalum brought in.”

“The next project was the BMW steering housing and then did the MT82 gearbox rear case, the Georgio clutch/rear housing and the B6 Plus which is a larger derivative of the original B6.” Alluding to the ‘cost-per-piece’ relationship, Ted continues: “In real terms, we have a tooling package that can cost ‘X’ amount. Within that cost, we work out the tool life projection and how long it will last. With the cost of the tool and the number of re-grinds or repairs in the case of PCD, we can then work out a ‘cost-per-piece’ on each particular tool. You can take all of the tools for a project, say 30 tools for example and we will calculate a ‘cost-per-piece’ and supply that information to Castalum, as they know what cost they are selling their parts to their end users. So, in ‘cost-per-piece’ and tool management, we are looking after all the tooling. This means Castalum don’t have to order any tooling or they don’t have to repair any tooling. We are doing the re-grinding of tools and we’re also helping with the tool-setting.”

Castalum supplies parts to the UK, Germany, Poland, Canada and Mexico and recently won its first order from a truck manufacturer in the Far-East. Now, 80% of all production is for export, with components going into vehicles produced by Jaguar, Aston Martin, BMW, Ford, General Motors, Fiat, Renault, Porsche and Mercedes. Today, one in ten vehicles produced in Europe has a steering gear housing manufactured by Castalum in Welshpool.

Alluding to how volume manufacturers can work without a complete tool management service like that offered by MAPAL, Ted continues: “Manufacturers can work without such a service, but this service genuinely makes them more competitive. This is because we also offer the service at the beginning of new projects and we get very heavily involved. This means we are offering engineering solutions. We help customers with situations such as how the parts should be clamped and fixtured, we look at the entire process and we look at the most efficient optimisation route for the tooling package.”

Alluding to how volume manufacturers can work without a complete tool management service like that offered by MAPAL, Ted continues: “Manufacturers can work without such a service, but this service genuinely makes them more competitive. This is because we also offer the service at the beginning of new projects and we get very heavily involved. This means we are offering engineering solutions. We help customers with situations such as how the parts should be clamped and fixtured, we look at the entire process and we look at the most efficient optimisation route for the tooling package.”

“We like to think of ourselves as solution providers and Castalum has been a fantastic experience where we have proved that we can work with customers in a way that can provide the most economic production results,” concludes Ted.

Discussing how the ISO: 14001, TS: 16949 and company has evolved the design and manufacture of its castings over the last two decades, Castalum’s Mr Radcliffe concludes: “Things have changed substantially down the years and we are probably at the forefront of using additive material formes in dies. Once again, this is something that MAPAL have helped us with. Whilst the castings we produce using additive formes are much cleaner, better looking and give great durability; we also had to interface with MAPAL to make sure their machining processes and products matched-up to the change of material properties that we aim to achieve in our castings.”