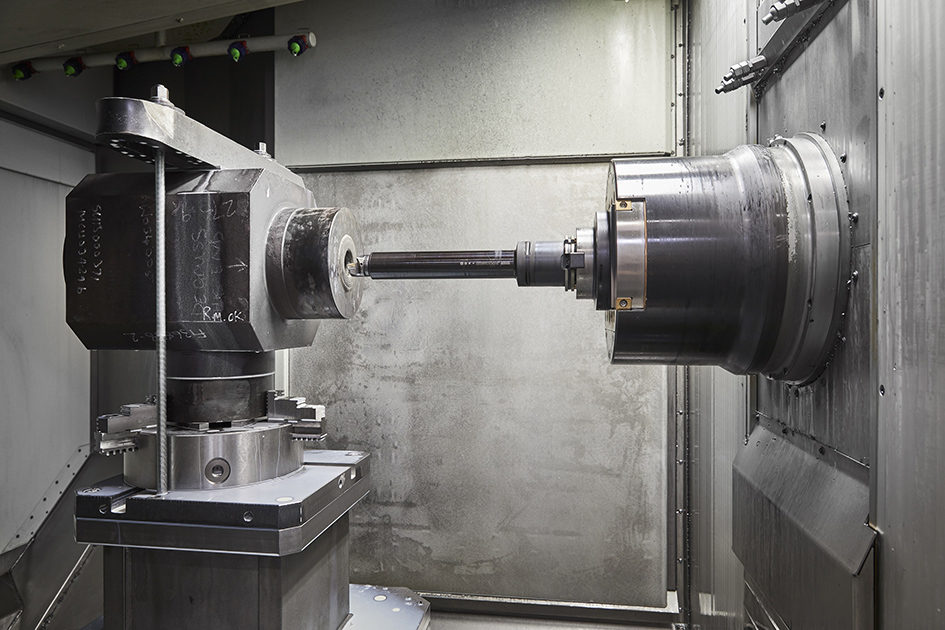

KOSO KentIntrol’s latest investment in the Starrag Group’s Heckert 630 DBF horizontal machining centre is paying big dividends in the machining of valve bodies, not least because the machine’s ability for single set-up, multi-tasking machining – milling, turning and drilling – has eliminated the need for two separate machines, and all the associated re-setting and queuing times, to produce finished workpieces.

The success of the DBF machine builds on the prowess of the company’s other Starrag brand machines – in particular, a Scharmann Ecoforce HT2 with integrated P600 facing head that has consistently and reliably proved its worth in the single set-up machining (milling, boring and turning) of larger workpieces at the company’s Brighouse (West Yorkshire) site.

And the Heckert DBF’s record in increasing KOSO KentIntrol’s machining capacity of smaller valve and globe bodies, and its ability to effectively transform the production process for such parts, is now similarly attracting acclaim.

“In addition to replacing separate machining operations, the Heckert DBF has effectively ‘simplified’ the production process by allowing us to load once with raw material, undertake complete machining, then unload a finished part ready for inspection. That also means we’re effectively getting more parts per week from that machine than we were using separate machines by, of course, eliminating queuing times,” says Richard Addy, Machine Shop Manager.

“The elimination of multiple set-ups on a lathe, plus the queuing and set-up times for drilling, has produced dramatic time savings,” he adds.

Established in 1967 (as Introl) and now a leading worldwide supplier of a wide range of valves (choke, control and butterfly), as well as actuators and instruments to a global customer base throughout industry sectors such as oil and gas, petrochemical and power generation, KOSO KentIntrol purchased the Heckert DBF to increase capacity of the machining of valve and globe bodies in the 1-6 inches range (flange outlet bore size) and from a variety of materials, from carbon steels through to super duplex and Inconel.

“We were previously using two machines to complete the bodies,” continues Mr Addy. “A lathe to produce the flange and plug-way in three operations; then the part had to often queue for a separate operation (and additional set-up) on a drill, the final operation.

KOSO KentIntrol’s latest investment in The Starrag Group’s Heckert 630 DBF horizontal machining centre is paying big dividends in the machining of valve bodies at KOSO KentIntrol – not least because its ability for single set-up, multi-tasking machining has eliminated the need for two separate machines, and all the associated re-setting and queuing times, to produce finished workpieces

“In needing to increase capacity, and with a good working relationship with Starrag, we had no hesitation in selecting the Heckert 630 DBF which offers a machining capability and specification that more than meets our needs for valve body machining: 630 mm by 630 mm pallets: X, Y and Z Axis travels of 1,070 mm, 870 mm and 1,200 mm, respectively, and traverse speeds of 40, 40, 60 m/min in X, Y and Z; plus +/- 35 mm in the U (turning) axis; a 45 kW/1,700 Nm spindle.

“The DBF machine enables the production of complete body machining in one or two operations, depending on casting type and size,” says Mr Addy. The DBF strategy – for angle bodies in one-hit and for globe bodies in two operations of set-up for machining the plug-way (including drilling) then set-up and machine the flanges (including drilling) – has replaced a comparatively longer and laborious process of:

[] Load to lathe

[] Set-up and machine first flange

[] Set-up and machine second flange

[] Set-up and machine the plug-way

[] Move body to drilling cell

[] Set-up and drill.

KOSO KentIntrol’s association with Starrag stretches back over many years; indeed, its heavy machine shop exclusively features Starrag brand machines – a Solon 4 machining centre and a Dorries vertical turning lathe plus the Scharmann Ecoforce HT2 machining centre equipped with integrated P600 facing head.

With X, Y and Z axes capacities of 2,000/2,500 mm by 1,600/3,500 mm by 2,200/3,650 mm, respectively, and able to accommodate workpieces of 10,000 kgs, the Ecoforce not only offers the capacity for the company’s larger workpieces but also the power – a main spindle rated at up to 63 kW spindle that produces 4,000 Nm of torque for even the heaviest of milling and boring cuts, and the facing head for in-process turning at up 300 revs/min.

“We’ve proven the reliability and consistently high-quality machining results from our Starrag machines and, coupled with the fact that we’ve always received excellent after-market back-up and support from the company, it made complete sense to continue that single-source association when we needed to address the throughput needs of our smaller valve bodies,” says Mr Addy.

“We also knew that the multi-tasking, single set-up benefits we would gain by using Heckert’s DBF head made even more business sense and has really brought to life Starrag’s philosophy of ‘Engineering precisely what you value’.”

The Heckert DBF machine features an integral U axis that carries Starrag’s innovative DBF multi-tasking head for a wide range of internal and external machining operations.

The DBF spindle head comprises a faceplate with integrated work spindle and CNC radial facing slide. For turning on a fixed workpiece, the rotating turning tool – which has an axial runout of just five/six microns – can be radially adjusted by +/- 70 mm. In addition to external, internal and face turning, the head also permits conical and contour turning courtesy of the radial facing slide’s NC axis.

For milling and drilling, the work spindle is arranged in its central position.

Mr Addy confirms that KOSO KentIntrol makes good use of the machine’s 45 kW, 3,500 revs/min and 1,700 Nm torque spindle by, for example, often applying a high-feed Capto milling cutter on carbon steel (WCB) at speeds of 850 rev/min and feeds of 3,000 mm/min.

He continues: “The machine is really rigid and on softer materials we are taking cuts of 2-3 mm deep – on Duplex bodies, for example, we’re taking 3 mm cuts at speeds and feeds of 60 m/min and 0.25 mm/rev. But it is a careful balance between cutting depths and speeds and tool wear; we aim to prolong tool life as much as we can. This is especially so when milling the rear of flanges – an operation that can be particularly onerous on the wear of the ‘slitting saws’ used.

“In addition to working closely with Starrag on the initial fixturing, Starrag engineers also played a key role in helping us establish the DBF process(es) and programming,” says Mr Addy, “which meant the machine was immediately into production and saving us money.”