Last year Roemheld Rivi, a manufacturer of magnetic clamping plates for securing dies and moulds, enjoyed growth in sales in all areas of the plastics processing industry as well as in forming technology and in 2019, order numbers and revenue continue to grow. The products are available in the UK through Roemheld UK, Hitchin.

At the K 2019 trade fair, the company will not only stress its prominence in the plastics sector but also in the rubber industry. It is the only magnetic die clamping company to have the technology to operate in the latter sector due to the ability of its M-TECS series plates to withstand temperatures up to 240°C.

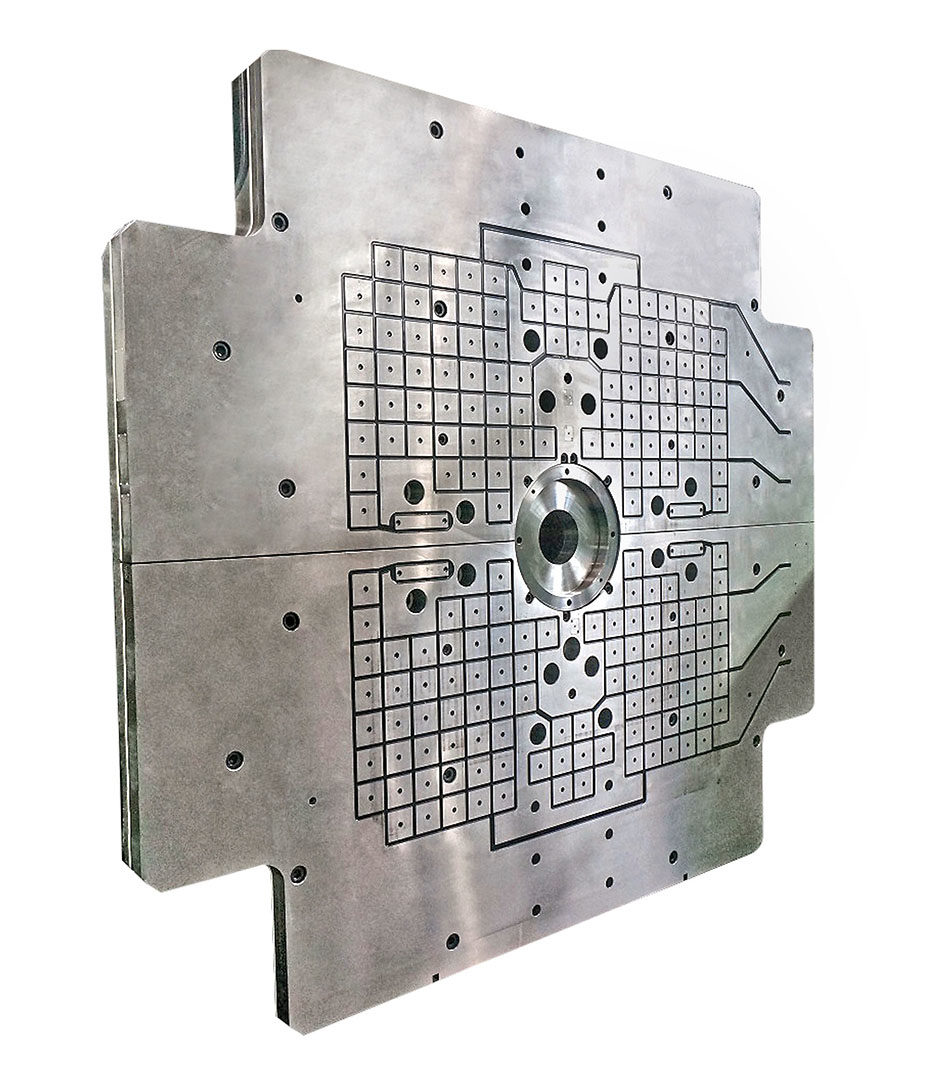

Dies and moulds made from ferromagnetic materials can be clamped and subsequently released over their full surface area and high plate stiffness resists bending. The systems work without electrical power and require only a short current pulse lasting a few seconds to activate and deactivate the magnets.

Permanent magnets generate a field that penetrates a few millimetres into the tool and hold even heavy mould halves weighing several tons in the correct position, bringing them together with absolute parallelity. Even moulds with complex geometries can be precisely clamped without deformation. Uniform distribution of the clamping force ensures low die wear.

Every magnetic clamping system is customised by Roemheld Rivi using standardised components and is virtually maintenance-free. Solutions can be configured flexibly with regard to size, geometry, clamping force and fittings, and are available on short delivery. They can generally be retrofitted to existing machines within just a few hours.

To be announced also at K 2019 is the formation of a new network comprising 15 service locations throughout Europe and one each in the USA, China and Japan. Intensively trained Roemheld Rivi engineers will provide enhanced support for customers in their native languages and each centre will have access to replacement parts to speed service and support.