New, compact workholding systems that are well suited to metalcutting operations on 5-axis machining centres have been introduced by Roemheld UK. They are manufactured by the German group’s Hilma division in Hilchenbach.

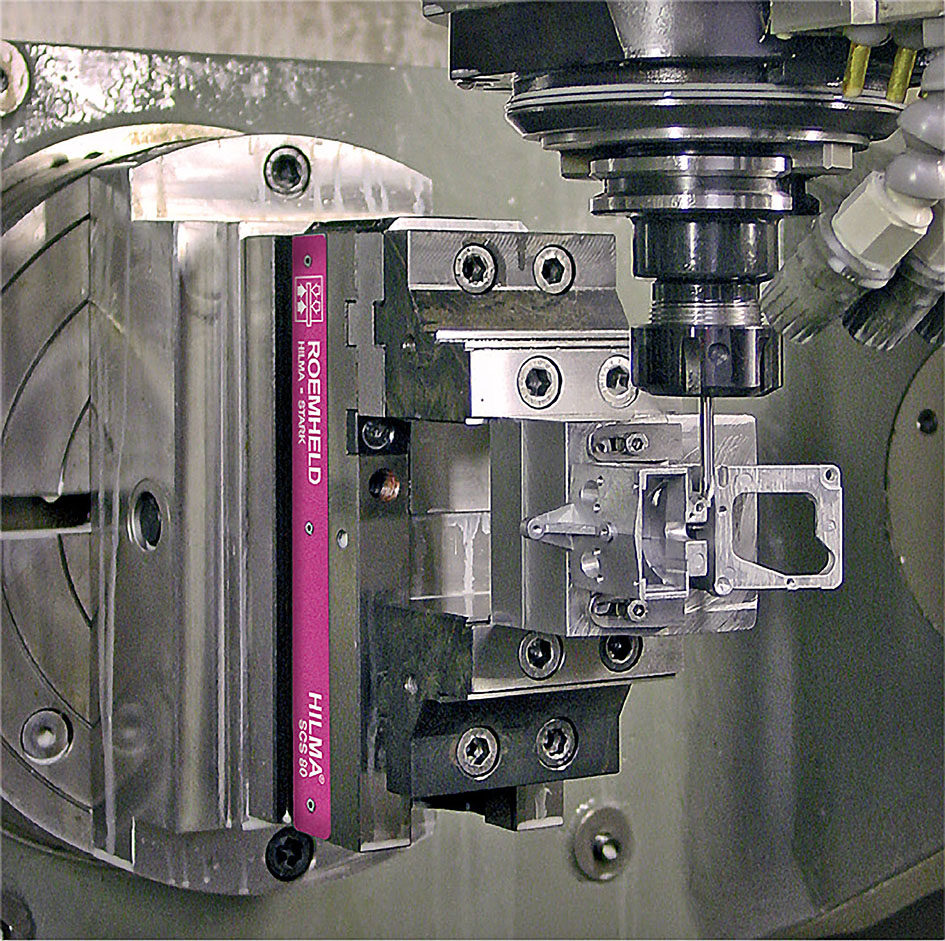

The design of the fixed-jaw SCS vice is compact and allows good accessibility of tools to the component. It means that five-sided machining can be achieved without collision using short standard tools, lowering costs and improving workpiece accuracy due to the generation of less vibration.

Stability of the clamping systems and high retention force resulting from the use of a reversible jaw mean that there is no need to pre‐stamp a workpiece before it is secured, even when it is clamped on just a few millimetres of material. Repeatability of positioning is to within ± 10 microns.

SCS workholding systems are of top precision, feature high stability and have comprehensive swarf protection, so are also suitable for use in multi-pallet prismatic machining cells. Operation is either mechanical via a threaded spindle and torque wrench or hydraulic using a single-acting cylinder to effect the clamping pressure, with unclamping achieved by spring force.

A variety of base lengths up to 350 mm is offered, with different clamping ranges to 300 mm, while clamping force is up to 40 kN at 100 Nm. An extensive range of hardened and ground jaws, as well as soft jaws, in 80 mm and 120 mm widths to suit the various vice models is available, as are customised versions in other lengths or with individual mounting holes including for zero-point clamping.