Tooling expert Walter GB joined forces with workholding specialist Schunk Intec to host a customer innovation day to showcase best-in-class five-axis aerospace machining at the Knowledge Transfer Centre in Sheffield.

A packed audience of aerospace production specialists not only learnt about how the companies’ new tooling and workholding innovations could bring substantial benefits to the machining of aluminium wing ribs, but they could also see the results for themselves in the adjacent AMRC with Boeing Centre where a demonstration part was machined on a Starrag Ecospeed machining centre. (The Ecospeed is one of eight Starrag machines in-situ at the AMRC and the accompanying Nuclear AMRC.)

Jim Dale, Walter’s Component Manager, Business & Application Development, outlined the distortion (and machining) challenges presented when producing one-hit finishes and tight corners, for example, on such aluminium workpieces with wall thicknesses that may be only 1.5 mm thick and corners with 6 mm radii.

Developing and supplying ‘pre-set’ tooling packages to suit many different machining platforms and processes is one of the strengths of Walter’s Engineering Kompetenz strategy,” he added. “And in terms of our aerospace customers, it is successfully being applied globally to titanium and aluminium structures, as well as to engines and landing gear programmes.”

The sample wing rib – measuring 1,500 mm long by 280 mm wide and 80 mm high, and with pockets up to 50 mm deep – was jointly designed by Walter and Schunk Intec to specifically show the ability of the companies’ tooling strategies and workholding technology in overcoming these difficulties in a controlled manner.

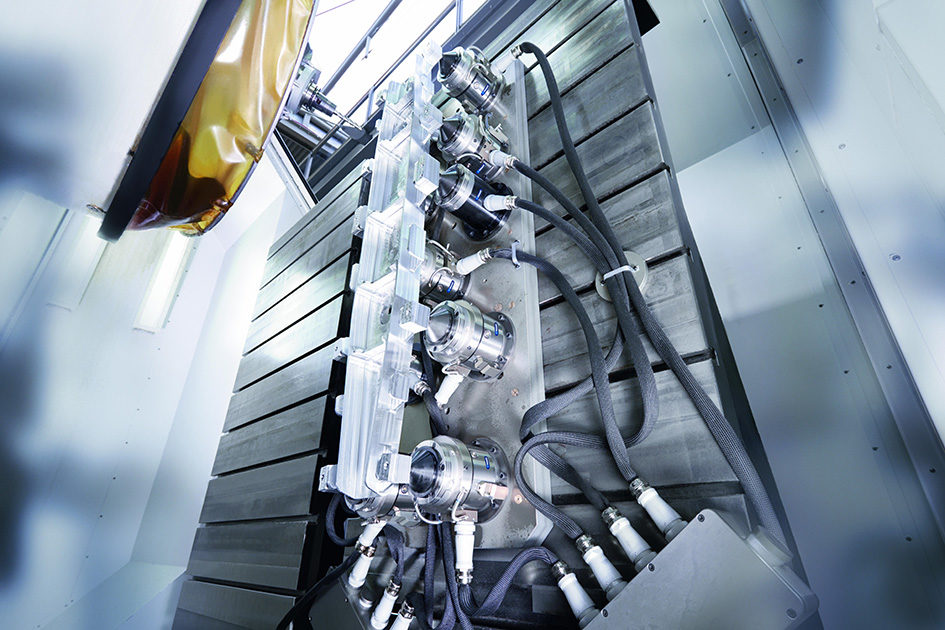

He continued: “In addition to applying a number of new Walter milling cutters, including an innovative three-flute cutter and inserts with a newly-developed coating for extended tool life, together with Schunk Intec’s Vero-S Aviation system we have arrived at the ideal solution.”

Vero-S (a pneumatic system) enables all component stresses to be relieved between machining operations by simply releasing then re-clamping the workpiece in-situ – without the need for separate set-ups. “Importantly, we wanted to achieve similar cycle times as if we were using a ‘fixed’ clamping system,” said Mr Dale.

As a result, Walter has arrived at a ‘toolbox’ specifically to suit the Ecospeed and the workpiece in question, with pre-set feeds and speeds for the tooling to match the machine’s impressive 120 kW/30,000 revs/min spindle and the capabilities of its Sprint Z3 machining head.

“Developing and supplying ‘pre-set’ tooling packages to suit specific machining platforms and processes is one of the strengths of Walter’s Engineering Kompetenz strategy,” he added. “And in terms of our aerospace customers, it is successfully being applied globally to titanium and aluminium structures, as well as to engines and landing gear programmes.”

Commenting on the success of the event, Walter GB’s Business Development Manager, Neil McKinnell, said: “The event was a great success when taking into account we were addressing a niche part of the aerospace manufacturing industry.

“There is significant movement in the aerostructure machining sector with regard to establishing best practice, in line with projects aimed at next generation aircraft, and we were able to show that we are fully aligned with these OEM and Tier One initiatives.

“We have received very positive feedback and significant interest in the machining strategies and tooling that were demonstrated.”

Likewise, Schunk Intec’s General Manager, Marcel Machado, also commented favourably: “We couldn’t be happier. The event was a great opportunity to show a complex technology performing live. Attended by a highly technical group representing all the main names in the aerospace industry, the event was a true reflection of the work being performed at the AMRC.”