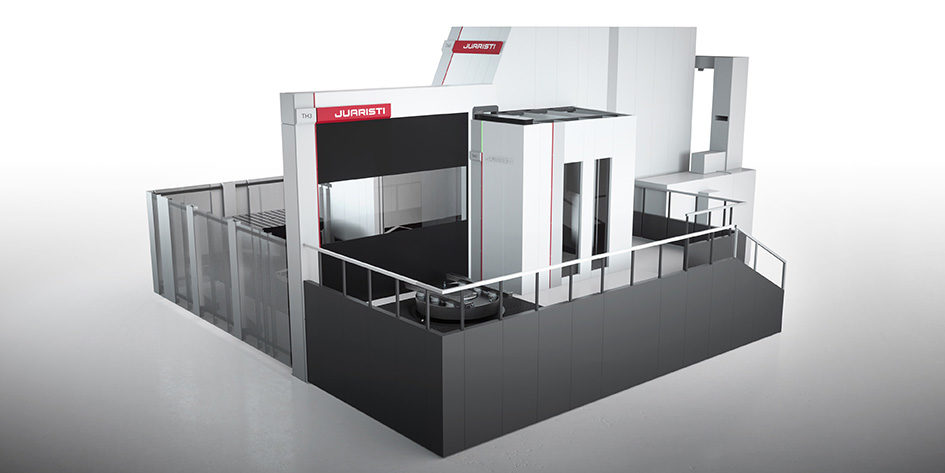

For JUARISTI, a company specialising in the design and manufacture of premium machining solutions, the EMO 2019 trade fair will be a huge opportunity to present the most disruptive developments of the last year. On this occasion, the company will be exhibiting the advantages of the new TH3-MT Multitasking Machining Center, its commitment to fulfil the needs of customers who demand a machine capable of performing multiple milling and turning operations with greater productivity and precise results, and the new range of 5-axis universal heads.

Productivity, increased autonomy and improved accuracy. These are the axes of JUARISTI’s innovation strategy, which in recent months has led to the development of the new TH3-MT Multifunction Center, optimised for highly reliable boring, milling and Turning operations, and the new ACD7 and ACD8 universal heads, designed for maximum precision 5-axis machining.

The new machining center is a new development in the TH series, the JUARISTI 5-axis Multifunctional Centers, which this time includes a milling and turning table and a special milling

head with an optimised design for milling and turning operations. The centre includes a comprehensive automation package and has been completely redesigned to improve ergonomics, extend service life and optimise swarf and cutting fluid management. The TH3-MT continues to offer the key benefits of TH series solutions: high dynamics (up to 40m/min rapid feed with 3m/s² accelerations) and interoperability with the next generation high feed and high swarf removal tools. Thanks to its symmetrical design with a column-centred head and 4 guides (two front and two rear), it offers unbeatable precision, thermal stability and high cutting power.

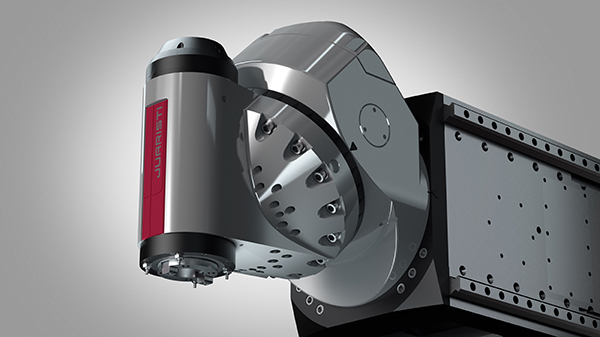

The major breakthrough has been the introduction of a new special head for turning and a turning table. JUARISTI’s new head, dubbed the ACD8, is a universal model that allows 5-axis machining and reaches rotation speeds of up to 8,000rpm, with high power (60kW) and spindle torque (1,600Nm).

The milling and turning table included in the machine will have a Ø1600 chuck diameter (options up to Ø2000) with a 400rpm maximum speed and a 5 tonnes maximum part capacity in turning and 10 tonnes in milling. Rotation speeds reach 400rpm. The new machine features multiple automated systems that can be adapted to customer requirements, including a quick-change matrix tool changer with the capacity for up to 200 tools and an FMS multi-pallet system.

The milling and turning table included in the machine will have a Ø1600 chuck diameter (options up to Ø2000) with a 400rpm maximum speed and a 5 tonnes maximum part capacity in turning and 10 tonnes in milling. Rotation speeds reach 400rpm. The new machine features multiple automated systems that can be adapted to customer requirements, including a quick-change matrix tool changer with the capacity for up to 200 tools and an FMS multi-pallet system.

Finally, the TH3-MT has gone through an extensive redesign process, achieving a more stylish and ergonomic ensemble. The new design achieves a more compact layout for better floor space usage. Plus, it optimises the swarf and cutting-fluid collection system, improving the solution’s autonomy and avoiding unproductive downtimes due to manual cleaning.

Another design enhancement is the stainless steel housing of the full enclosed guarding, which protects and extends the life of the machine. Its excellent ergonomics mean that the operator has perfect control of operations, as well as the meticulous arrangement of the main components to facilitate monitoring and maintenance, with maximum safety.

New range of milling and turning heads

JUARISTI heads are well-known in the market thanks to their very high rigidity and great performance. Now our design department delivers a stroke of genius with a 5-axis universal head

model that will enable high-precision milling, turning and boring while minimising tool change time.

The results of this innovative drive have been the development of not one, but two top universal head models targeted at different types of users: the ACD7 and the ACD8.

The ACD7 stands out for its double continuous rotation axis (horizontal and 45º) and for achieving very fast repositioning movements (from 0 to 180º in 7 seconds). In terms of both features and performance, they stand out for a rotation speed of up to 6,000rpm. On the other hand, the new ACD8 spindle is a development that integrates all the technology of

the ACD7 but which also allows turning operations using the spindle unit. It has a continuous 45º rotation axis with a double pinion system, with spindle speeds of up to 8,000rpm. The head, thanks to its sturdiness, enables demanding turning operations by automatically changing the turning attachment.

Due to their fast positioning times and interpolation capacity with the other axes, both models achieve a drastic saving in tool change times, greatly increasing productivity.

Due to their fast positioning times and interpolation capacity with the other axes, both models achieve a drastic saving in tool change times, greatly increasing productivity.

These new developments are part of the C.A.S.T. strategy (Connectivity, Automation, Service and Technology), concepts that guide JUARISTI’s customer service relationships. These areas will be the focal points of the company’s efforts in innovation and development to satisfy all the customers’ needs for maximum versatility, to improve businesses through high-level services and to build interconnected machines that work together efficiently and intelligently.

JUARISTI, experts in milling and boring multifunction centers, has been a leader in the machine tooling industry for more than 75 years. Its headquarters are located in Azkoitia (Gipuzkoa, Spain) and its product range covers all types of milling and boring machines, as well as multifunction centers.