Traditionally a 3-axis vertical machining centre (VMC) user, Singer Instruments (www.singerinstruments.com) in Watchet, on the north coast of Somerset, installed its first 5-axis CNC machine at the start of 2019 to streamline the manufacture of aluminium components.

The German-built Spinner U5-630, a 40-taper, nominally half-metre-cube machine, was supplied through sole UK agent Whitehouse Machine Tools, Kenilworth (www.wmtcnc.com). It is equipped with high pressure coolant through the spindle and a separate clean tank, as well as Blum spindle-mounted workpiece probing and a tool setting probe.

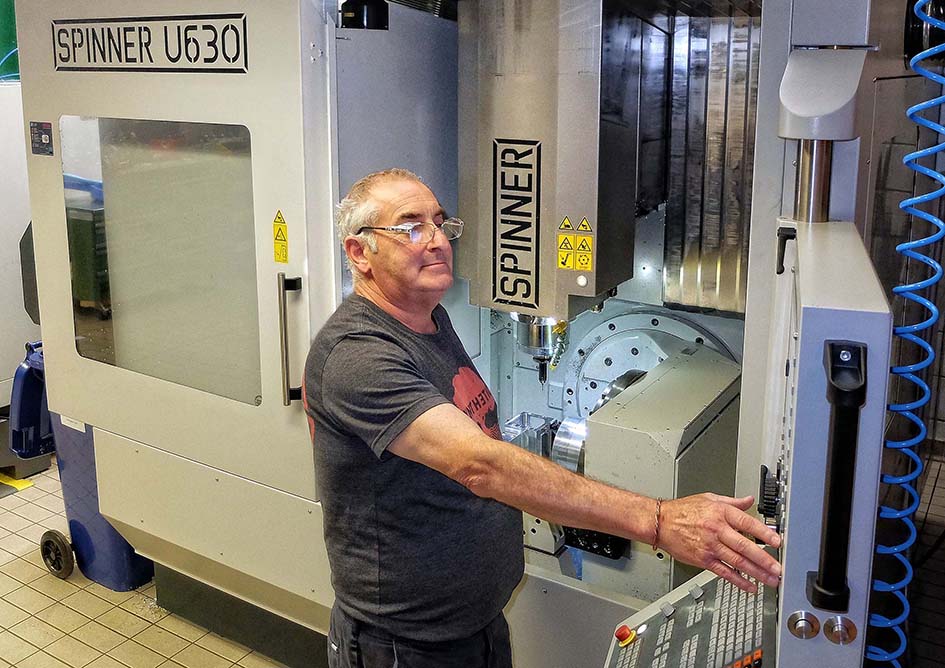

Steve Maconnachie, CNC Machinist at Singer Instruments, with the Spinner U5-630.

Cycle time savings have been dramatic and there has been a considerable reduction in the number of set-ups needed across a raft of different parts. It is a result of using the two additional rotary CNC axes provided by the swivelling trunnion and rotary table to reposition components automatically.

In one case, a table for Singer Instruments’ world-leading ROTOR automated screening instrument used in the biological sciences sector is produced in three set-ups, whereas previously it required nine separate prismatic machining operations on a 3-axis VMC.

More typically, components previously needing six operations are now produced in two. In one such example, for producing another integral part for the same genomic screening instrument, machining cycles totalling three quarters of an hour have been reduced to eight minutes.

In addition to higher production output, other benefits of fewer set-ups include less handling, lower fixturing costs, and enhanced accuracy through fewer clampings. Furthermore, with average batch size in the range 10- to 20-off, a lot of work in progress is eliminated.

he Spinner U5-630 5-axis machining centre at Singer Instruments’ Watchet factory.

Investment in 5-axis capacity was instigated by Steve Maconnachie, CNC Machinist at Singer Instruments. He previously ran his own subcontract machining business with his brother in the Midlands and had used 5-axis technology for many years. He was familiar with all the leading makes of machine, many of which were reviewed before deciding on the Spinner purchase.

He commented, “Some of our components are tightly toleranced to ± 5 microns, so we maintain the temperature of our production area to within a couple of degrees Celsius.

“It is true that many of the 5-axis machines we considered could hold this tolerance, as does the Spinner, whose price was also competitive. It was little more than half the cost of one of the other production centres we shortlisted.”

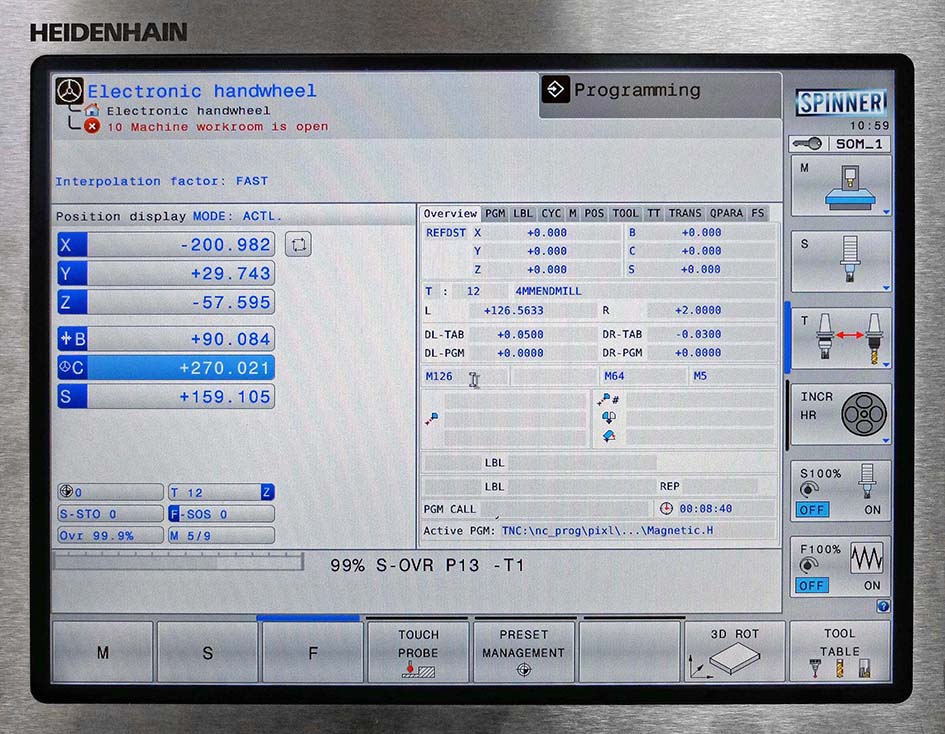

A Heidenhain TNC 620 control is fitted to the Spinner, rather than the Siemens equivalent.

He singled out for praise the service provided by Whitehouse, which included helping to remove the 54-pocket tool magazine and Z-axis motor so that the machine would pass through the door to the building. On the shop floor, the U5-630 has a compact footprint of a little over 2.7 x 2.4 metres, which is beneficial as space is limited in the factory.

Every component used in Singer Instruments’ products is designed in-house using SolidWorks. Based on the models created, programming is carried out in FeatureCAM on a PC and data is transferred to the Spinner’s Heidenhain TNC 620 control via the latter’s TNCremo software. All the other machining centres on the shop floor also have Heidenhain controls similarly linked to the CAM system.

Currently, all 5-axis cycles involve 3+2-axis cutting strategies, as components have historically been designed for production on 3-axis machining centres.

However the Spinner machine is capable of fully interpolative 5-axis machining, so parts being designed for new electronic workstations and laboratory automation equipment, used worldwide for research into genetics, neuroscience, cancer, biofuel engineering and microbiology, will be designed more efficiently with the Spinner machine’s enhanced capability in mind.