Advanced EDM machines and software from GF Machining Solutions, working in combination, enable the machining of accurate angles and tight radii plus low tool (electrode) wear.

EDM is a non-contact metal removal process that can cut complex shapes with accuracies up to +/-1 µm and generate surface finishes finer than Ra 0.1 µm in hardened and difficult-to-machine conductive materials, without the creation of distortion or stress.

Consequently, wire and die sinking EDM offer, in some cases, the only practical way to achieve the precise component accuracies and finishes required in critical applications for the medical, aerospace, electronics and other industries.

Maintaining such high levels of accuracy, especially when it comes to achieving corners, sharp angles and tight radii, requires close control of multiple elements in the EDM process.

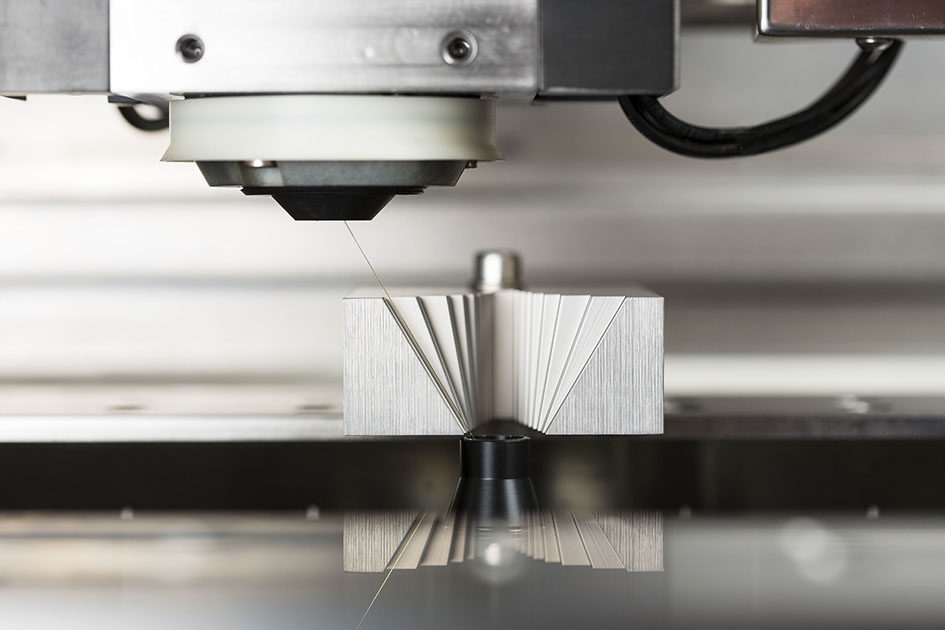

In wire EDM, for instance, a key issue concerns achieving consistent production of corner radii.

Wire EDM is capable of producing corner radii barely larger than the radius of the cutting wire itself. However, in parts such as stamping dies, a corner radius that is too small can become a geometric stress point where cracks can occur.

Choose the right wire

CAM software for EDM provides a way to relieve excessively tight corner radii. In cases where a machined radius would be too tight, the software can be set to direct the wire to move in small loops – similar to a trochoidal milling path – to relieve the radius

Generating very sharp internal angles also can pose a challenge. In some situations, the wire diameter may be too large to erode the full depth of an acute corner, much like attempting to machine an intricate feature with an end mill that is too big. The reason is that the EDM machine control maintains a set spark gap, or offset, between the wire and the workpiece to achieve a desired material removal rate at a certain power level.

A wire diameter that is too big for the application will reduce the offset to the degree that machining stops before completing the angle. Use of a smaller-diameter wire enables machining of acute angles – but smaller diameter wires cut more slowly and are more prone to breakage, making them impractical for more general use.

A productive alternative is a machine with an automatic wire changer that enables quick exchanges between two spools of wire that can be completely different in terms of wire type (i.e coated/uncoated etc.), and wire diameter.

So, in effect, a wire EDM machine could perform roughing operations and cut large features with large-diameter wire then automatically change to a spool with small-diameter wire to cut the very tight part details.

Control cut parameters

When a wire EDM operation is initialised, achieving accurate results in sharp corners or tight radii depends on a multitude of factors. These include wire type, diameter, tension, and feed conditions; workpiece material and thickness; dielectric type, flow, and temperature; and spark power and duration.

Traditionally, fine-tuning an EDM process required cutting a test part and then removing it from the machine for measurement on a CMM. After remounting the part on the machine, the operator consulted the CMM data to note deviations from the desired part dimension and made changes in the machining parameters with the hope of achieving an acceptable part.

A newer, and more reliable and faster approach uses a closed-loop vision system to measure the part and make in-process corrections.

While the part remains in the machine, the system’s camera scans the part contours and compares them to the part’s DXF CAD file. If the part is out of specification, the system employs what is called a ‘contour modifier’ that directs the machine control to correct the EDM path to produce a part within 2.5 µm of the required dimensions.

A vision system can also facilitate with the quick location of a part before machining begins, saving the time and wire invested in the traditional part location method that uses the wire itself to locate the part on the machine.

Control of the wire’s path when producing inside and outside corner radii is another important element of EDM process accuracy. When the EDM wire rounds a corner, it can act somewhat like an articulated lorry making a turn -where the front wheels track perfectly but the rear of the trailer swings wide.

While EDM wire guides hold the wire’s position above and below a workpiece, the wire’s middle section between the guides may bulge or swing wide during the cutting operation.

Advanced EDM machines and software provide methods of anticipating and eliminating such a swing, thus reducing the risk of exaggerated corner paths.

Twenty years ago, controlling corner machining required manually updating the CAM program to reduce power as the wire entered a corner. Reduced power/spark intensity then permitted the application of greater wire tension to eliminate swing-out and increase accuracy without causing the wire to break.

Today’s EDM software packages have a look ahead facility and can change machining parameters in anticipation of upcoming part features such as corners and radii. On some machines, for example, the software automatically reduces the intensity of the spark to prevent over-cutting on curves. However, spark intensity not only influences metal removal rates, it also dictates required offset amounts. When power settings lower, the offsets must change accordingly.

In many cases, however, decreasing power and also the flushing volume will increase the heat of the operation and keep material removal rates steady, eliminating the need to adjust the offset. For this reason the most common form of corner control involves pairing reduced power with adaptive flushing.

On a machine with a vision-based in-process measuring system, corner control can consist of reversing the wire path after traversing a corner and backtracking to complete the desired amount of metal removal. The reverse pass will be faster than the initial pass because a minimal amount of material is being removed.

Because the lower power employed in corner control slows the overall machining process, shops often opt to turn automatic corner control off when the slower cutting speeds are impractical. For example, implementing corner control when rough machining the multiple teeth of a gear generally consumes an unacceptable amount of time. An operator might choose to rough the gear shapes at higher cutting speeds and then return for cleanup passes that can run more quickly.

Another factor affecting the accuracy of EDM operations in terms of corners, radii and angles is the thermal condition of the cutting environment and machine. Wire guides set up first thing in the morning when a shop is 68 degrees F will perform much differently in the afternoon when that same shop is 78 degrees F and the machine is thoroughly warmed up. A typical negative effect of inconsistent thermal conditions is cone-shaped radii.

As a solution, some machines are thermally stabilised. The control system minimises thermal variations with the use of temperature-stable dielectric to cool the casting of the machine in conjunction with the machine’s X, Y, U, V, and Z glass scales.

Die-Sink process

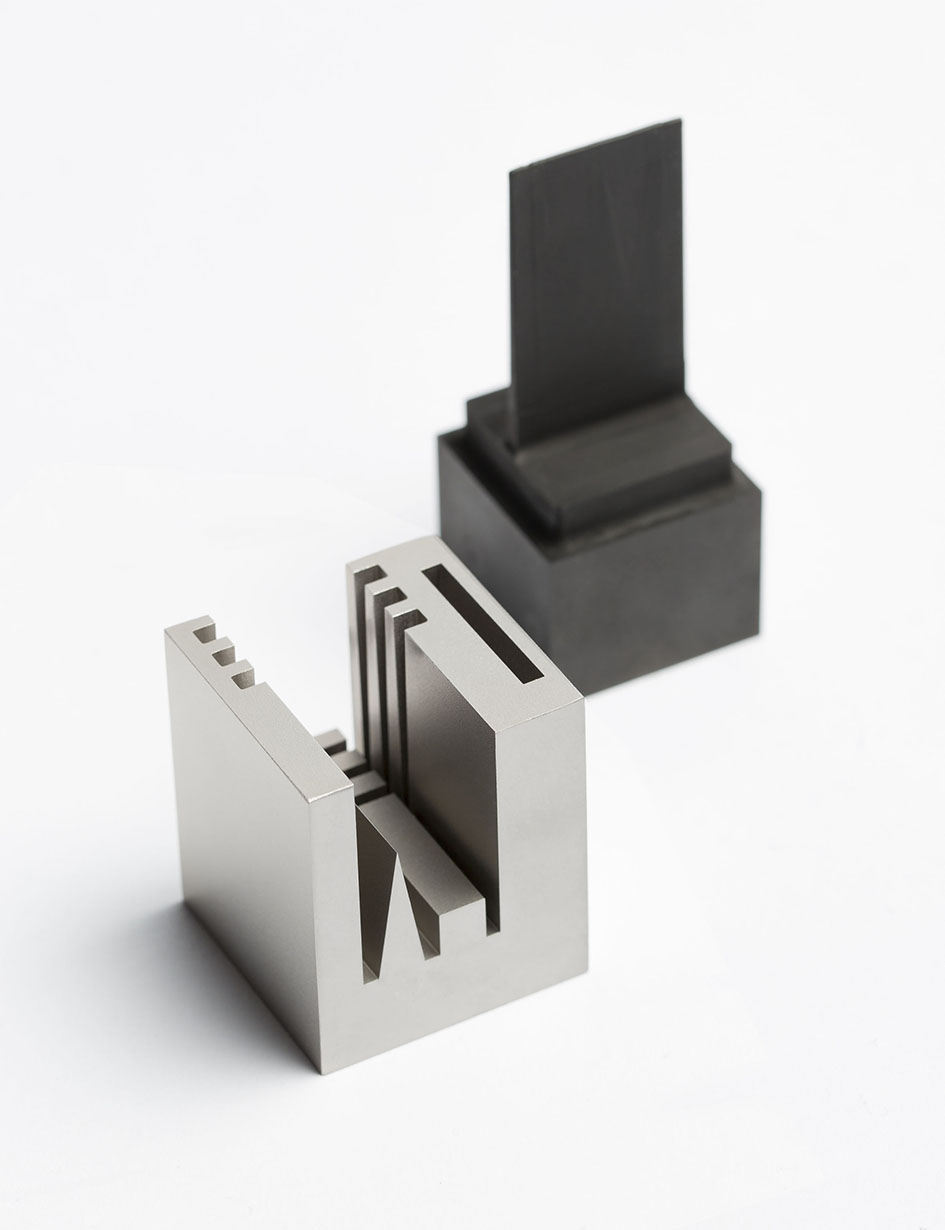

Die sinking EDM presents challenges different from those of wire EDM in regard to maintaining machining accuracy of corners, angles, and radii.

While the wire EDM process continually presents fresh wire (unworn electrode) to the workpiece and cutting zone, a die sinking EDM electrode begins to wear as soon as erosion starts and continues to do so throughout the process.

As the electrode wears, it gradually loses its ability to hold fine detail, so minimising electrode wear is critical to improving accuracy. Longer electrode life also helps reduce consumable (electrode) and machining costs.

The wear rate of a EDM electrode depends to a large degree on the material from which it is made. Conventional graphite conducts electricity well but wears quickly, so for creating sharp details, shops often apply electrodes formed from harder materials such as copper or copper/tungsten. These harder materials hold detail better than graphite, but do not conduct electricity as efficiently, so the result is slower machining.

Because lower cutting speeds extend electrode life but reduce productivity, EDM machine builders develop machine technologies and application strategies that balance cutting speeds with long electrode life and the ability to maintain sharp detail. (Usually EDM machining small, tight details requires multiple electrodes).

The normal progression employs one or more roughing electrodes followed by finishing passes with smaller electrodes. One application strategy to minimise the number of electrodes required to machine a part involves electrode staggering, or partitioning. Different electrodes are applied across multiple cavities in a sequence designed to maximise electrode life. Other process parameters, including the selection and duration of electrode orbit paths, are varied as well. While electrode wear decreases, overall burn time remains the same.

Reduce time and costs

To increase EDM accuracy and control costs, shops are demanding smaller wire EDM offsets and smaller undersize dimensions in die sinking operations.

The goal is reduced process time and expense. Shrinking offsets and undersize dimensions require precise control of the spark gap, causing EDM machine manufacturers to pursue advancements in spark generator and machine control technologies. One such advancement is 100 per cent-digital generators.

Complete digital generator technology has enabled the development of special EDM functions which are engineered to minimise electrode wear while optimising cutting speeds. On certain die sinking EDM equipment, the technology manages the electrical current between the fronts and sides of electrodes and controls its delivery to minimise lateral sparking that disrupts effective machining of areas such as the sides of mould cavities. The system allows the electrode to have maximum power in the front of the cavity without destroying or creating oversize gaps on the cavity side walls.

Another technology aimed at extension of electrode life is a zero-electrode-wear feature.

In both copper and graphite, GF Machining Solutions’ IQ technology captures the debris/chips of the EDM erosion process and uses them as a protective and “healing” layer on the electrode, maintaining its edges and ability to produce fine details.

The feature can reduce electrode use by two-thirds and in some cases permits the use of coarse graphite grades where finer grades were previously required. The technology also manages pulse efficiency to minimise wear and conserve electrode material.