The real time Status Board display system for the shop floor is the latest acquisition by Sheldon Precision Engineering for its PSL Datatrack production control software system. The fast-growing Barnstaple based company provides specialist subcontract engineering and turned parts manufacturing services which have been effectively managed using PSL Datatrack since the business started.

Managing Director, Howard Sheldon, says: “What sets us apart is our people and the culture we have of trying to provide the best service we can. I provide my team with the best equipment, tooling and support to enable them to be the best they can be.” With this philosophy and prior experience of using PSL Datatrack, Howard invested in the software on day one of the company’s trading. Its ability to improve production efficiency and, in his words, “cut out the paper shuffling” – the bugbear of many smaller engineering organisations – was essential to having effective business administration from the outset.

Continuous investment in a number of PSL Datatrack modules over the intervening years has not just prevented a paperwork burden but enabled the company to maximise the efficiency of its operation in all areas. The modularity of the software has allowed the company to add elements when it has suited in terms of the company’s growth. “With PSL Datatrack, you don’t have to invest in functionality you do not need immediately all at once. You know that each of their modules will seamlessly integrate with all the others and so you can take them on when you are ready,” says Howard.

PSL Datatrack manages everything from initial quotations to final invoicing and throughout this process also takes daily care of works orders, purchase orders, delivery notes, goods received notes, component and material stocks and also quality management.

Howard acknowledges that at the beginning some time had to be invested entering information into the blank canvas of their PSL Datatrack database but that effort has more than been rewarded further down the line with the ability to quote customers ever more quickly and transform quotations into works orders in a matter of seconds.

For repeat orders, PSL Datatrack has proven particularly fast – with a few clicks it recalls the information associated with previous quotations for a customer. Costs, tooling, materials and batch sizes can be recalled, analysis can be undertaken very quickly and new quotations for different batch sizes can be generated easily. What is more, all customer paperwork is presented professionally with corporate branding to create an excellent impression.

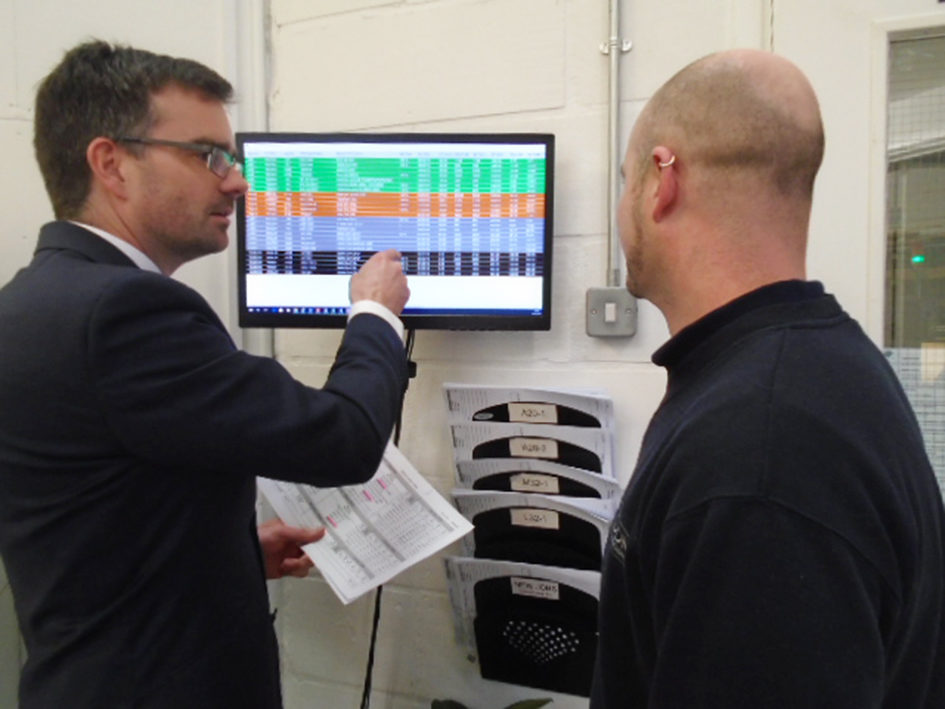

With production fully controlled by PSL Datatrack, attention was turned to improving communication between the management offices of the business and the shop floor. The company had been using printed lists to provide information on the sequence and detail of orders to be progressed through the factory on any given day. Circumstances, however, could change rapidly so that by the time an engineer had picked up the instructions another order may have arrived which needed priority treatment.

“We needed real time information to be readily available and so we turned again to PSL Datatrack for advice and a solution,” says Howard, who was impressed with the functionality of the Status Boards. They could provide real time visual information on any aspect of production, including the current work-to-list, all jobs requiring work that day and updates including whether any material or component stocks required to complete a job have fallen below minimum quantity levels and which customer deliveries are due out of the door. With this knowledge, informed decisions can be made about production priorities.

PSL Datatrack provided a customised Status Board to Howard’s specific requirements and he is delighted that the system is making a major impact on improving communications between office and shop floor. “This is key to ensuring our customers get the best service. Status Boards have cut out the difficulties that could be encountered by not having real time information available where it matters most – on the shop floor. We can now make better decisions on priorities, ensuring machines and materials are readily available to fulfil any order,” he says.

Indeed, Howard thinks his own company’s customers benefit from his investment in PSL Datatrack in one vital way – efficiency. “There are always efficiency gains when you invest in the latest technology, whether it is software, plant machinery or facilities. It is well known that in the UK productivity output per person is well behind that of major competing countries, so if we are to address this we must invest. PSL Datatrack has smoothed out and made my back office and shop floor systems flow seamlessly, giving us more time to be productive!” he comments.

Today, Howard says that PSL Datatrack is literally “running the Sheldon business.” It has played just as major a role in the development and success of the company as any of its other significant investments, whether these are state-of-the-art CNC lathes or quality management, including its ISO 9001:2015 UKAS certification.

The company is growing at 50% per year at present and will add further PSL Datatrack modules to help manage this. Whilst at the moment the business is still small enough for Howard to know exactly what is happening on all machines, there will come a time when extending the system to include Shop Floor Data Collection (SFDC) and a full-blown sequential scheduler will be necessary to manage work even more effectively.

The service and training provided by PSL Datatrack has also been positively reviewed by Howard: “I never get an answer machine and the company is well-staffed, polite and helpful. I would, and do, refer their services all the time. It is a great affordable system that has never let me down.”

Contact PSL Datatrack, Lily Hill House, Lily Hill Road, Bracknell, Berkshire, RG12 2SJ, Tel: +44 (0) 8456 345931, Email: sales@psldatatrack.com or visit www.psldatatrack.com