“We find that PSL Datatrack is much more than just an IT software service provider. As they deal with so many businesses they are able to offer advice on practical solutions for the day-to-day running of Empire Manufacturing.” That’s the verdict of Director Stuart Wade, whose precision subcontract engineering company has now been using the production control software system across two generations of the family business.

Based in Hoddesdon, Empire Manufacturing was established in 2008 as a precision subcontract engineering company providing its services to customers in the aerospace and automotive industries, among others. Specialising in 0-180 mm diameter CNC turning and milling as both primary and secondary operations on a range of components in many different batch sizes, the company has enjoyed steady growth after a tough start in a recessionary period. There has been continuous investment in additional machining capacity and inspection technology (including a new dedicated inspection department), as well as in their PSL Datatrack production control software.

When Stuart started Empire Manufacturing, he was managing it single-handedly whilst his father Peter was running a separate engineering company that already used PSL Datatrack. Stuart had also worked there and gained first-hand experience of the benefits of the software in the production environment. When Peter subsequently joined him at Empire Manufacturing the decision was made to take advantage of the software there too as it was proven, easy to use and had an industry-wide reputation. “It was really my dad’s decision to use PSL Datatrack at both companies and that was also mainly due to our familiarity with the software at the time,” says Stuart.

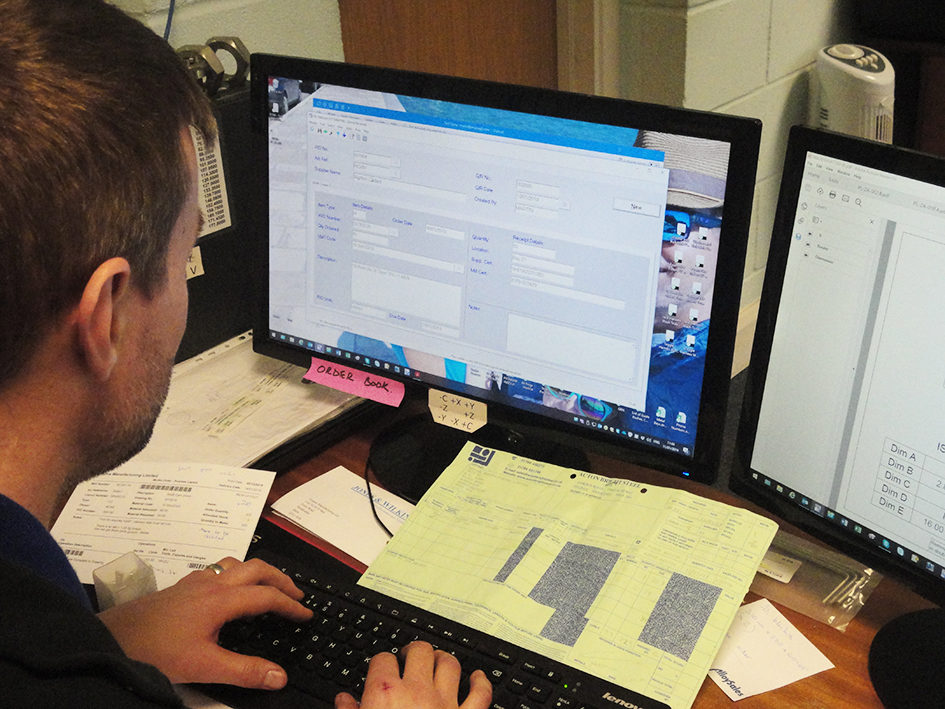

PSL Datatrack was used on a full-time basis within the new business and Peter became its main user in addition to providing the company’s own training manager with tuition in its use. The immediate requirement was for a single user licence for sales order processing and invoicing modules which were identified as being crucial to providing the level of business control required at that time.

As the company acquired a larger manufacturing unit to cope with increased business, the demands on Empire’s production and administration systems also grew. Extra PSL Datatrack modules were added to cover quotations, purchase order processing and stock control. The facility to be able to quote work for customers quickly and easily as well as having the facility to recall those quotes has been vital. “A major advantage for us is the time saved when preparing customer quotations,” says Stuart. “The ability to create new generations of existing customer quotes quickly and easily saves a huge amount of time.”

It was also important that works orders were organised properly and subsequent modules were added covering process layouts, to produce more detailed shop floor route cards, and document control, for managing incoming supplier certificates, and component drawings, to provide vital issue control. The number of user licences has also now increased to four.

“PSL Datatrack has provided a system that prioritises which jobs have to be done for which customers and when, in order to complete them within required time frames. Once an order has been placed, PSL Datatrack modules are employed throughout the production process, which also gives us the traceability that is now being demanded by our customers. This ability to view and track an order through its entirety, from the sourcing and stocking of any materials required to complete the order right through to the parts or assemblies going out the door and then being invoiced, is essential,” says Stuart.

Stuart says he could name lots of other specific benefits of having PSL Datatrack, including the traceability that PSL Datatrack provides on past jobs. “This is very important, as it would be to any manufacturing business. But the biggest one for us is the organisation side of it. In short, without the software we would be lost!” he says.

Since investing in basic PSL Datatrack modules at start-up when money was tight, and the company was operating from a single unit, Empire Manufacturing has since found it easy and affordable to add modules when needed as business has developed. This lean approach has continually improved internal organisation, helping to streamline new processes that have been implemented.

In this respect PSL Datatrack’s support has been invaluable. Stuart says: “The service from PSL is excellent. We always get a prompt response, with a workable solution to a production problem we may have or to a new process requirement that we want to implement. On the rare occasions there isn’t an immediate solution available from PSL Datatrack, it will be worked into the next update of the software. This forms part of their customer Wish List initiative which is very handy. It’s great to see our ideas actually taken on board and implemented,” says Stuart. That is just another reason why he sees the company as so much more than just an IT software service provider.