Walter AG, one of the world’s leading metalworking companies, has reinforced its market-leading status by announcing a flurry of developments in milling cutter technology – all designed to generate a raft of cost-savings and improved process integrity benefits, for users across all industry sectors:

A new PCD cutter able to machine both aluminium and bi-metal (grey iron-aluminium) workpieces by utilising a number of indexable inserts, each optimised for different applications;

Two new long-life solid carbide cutters (MC319 and MC320 Advance) specifically for roughing;

An expanded range of M4000 cutters of up to 315 mm diameter for larger workpieces; and

The next generation Xtra·tec XT (Xtended Technology) shoulder and face mills for increased productivity and process reliability.

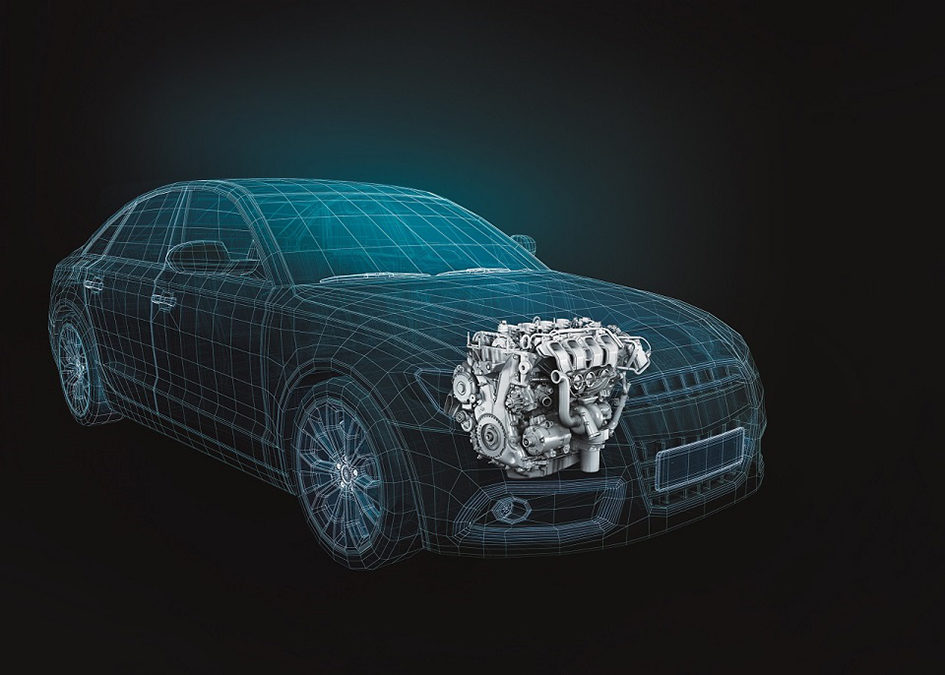

Of particular appeal to automotive OEMs and top tier suppliers, Walter’s new PCD cutter uses a variety of standard inserts in a single tool that is able to rough (up to 8 mm deep) and finish (0.5 to 0.8 mm) mill aluminium, and finish mill bi-metal workpieces. The cutter therefore reduces tooling costs by obviating the need for multiple tools for varying operations on different workpiece types.

While around 70 per cent of modern engine blocks are of aluminium, bi-metal blocks usually have components like cylinder liners of grey cast iron inserted into the aluminium body. The machining process, especially roughing and finish milling, of such workpieces was previously only possible using a range of different tools – therefore hoisting tool costs as well as increasing the time (and cost) spent on tool logistics and tool changes.

Aluminium alloys can be rough and finish machined extremely easily at high feed rates. However, process reliability and surface quality are influenced by chip removal and the formation of cavities. Added to this are the numerous cavities found on engine blocks, such as drilled holes, bushes and recesses. Of course, cleaning routines – an additional process step – add to overall production costs and does not guarantee that all chips can be removed.

Walter’s answer has been to design the new cutter with a coolant channel running through the centre of the tool, ensuring that the flow of coolant removes any chips.

An additional factor is the cavities that form during casting, which are ‘ripped open’ during milling and, if untreated, can result in leaks. Again, an additional milling operation is traditionally required to create a homogeneous finish where the porous surface is ‘filled in’. The new cutter overcomes this problem by being able to perform both finish- and lubricated-milling.

The new PCD milling cutter

Designed specifically for universal roughing of a variety of materials, the MC319 and MC320 Advance solid carbide milling cutters feature an innovative castellated profile for even longer tool life. Together with the MC320 Advance and MC320 ConeFit, users have three to eight cutting edges (depending on tool diameter) and an edge cutting to centre.

Cutting power requirement (spindle output) during machining is around 30 per cent

lower than comparable tools with smooth cutting edges. And the new cutters enable full slotting of up to twice the diameter with very short chips, a high metal removal rate and a particularly smooth milling process.

P_Mr_MC319-W-4-B-C_WK40TF_P_02.tif

The M4000 universal milling system is now available in diameters up to 315 mm (compared to the usual 160 mm) and with four cutting edges per insert, the universal inserts reduce inventory costs considerably. The design consists of a basic body plus with four adjustable and interchangeable cartridge types carrying Tiger·tec Silver and Tiger·tec Gold inserts.

The M4000 universal milling system

The most striking design feature of the next generation Xtra·tec XT (Xtended Technology) shoulder and face milling cutters is the position of the indexable inserts – at a greater radial seating angle and with a larger contact surface than traditional types, to reduce surface pressure in the seat while increasing stability. The larger screw hole cross-section stabilises the inserts and the longer screws hold them in place more securely. The cutter body is also very stable, with more material behind the insert seat.

In addition to greater process reliability, the position of the indexable inserts also allows for the addition of an extra tooth, thereby increasing productivity, and the precise 90° angle of the shoulder milling cutters helps to reduce additional finishing operations.

Also new is the fact that smaller inserts can be fitted and, particularly with the M5009 face mill, this combines small depths of cut with the advantages offered by double-sided Walter Tiger·tec indexable inserts that have eight useable cutting edges instead of the usual four.

For further information visit: www.walter-tools.com