Teixidó has been specialising in the mass production of precision parts since it was founded in 1952. Based in Catalonia, the bar turning company is the largest of its kind in Spain.

Teixidó operates in the automotive, pneumatic, equipment and aeronautics industries. The bulk of its production covers diameters from 0.5 to 20mm. As Spanish group sales director Xavier Teixidó Pont explains: “Many bar turners are capable of producing these diameters, but what distinguishes us from our competitors is our ability to adapt to the tightest tolerances. Our 13,500m2 production facilities and the diverse technologies we use in our company enable us to respond rapidly to varying demand from our customers.”

An integrated industrial approach

Teixidó is, first and foremost, a company offering very high performance and it is led by a team of highly-qualified specialists. With a workforce of 470 staff, the company has ISO: 9001 and ISO: 14001:2004 certification. Able to meet the strictest cleanliness requirements, Teixidó has its own plating and heat treatment department. In addition to bar turning, Teixidó has a classic centreless large-scale grinding machine, and its services also include polishing and honing. It produces over 300 million parts every year with an average PPM of 3. The company machines all kinds of material and offers hard turning operations. In addition to tempered steel, the offering covers an unparalleled range of materials such as bronze, aluminium, steel, brass, inconel, stainless steel, copper and titanium.

The Tornos EvoDECO

“Machining is our core activity. However, we also have a centre of competence for additive manufacture. This centre will soon be equipped with our first 3D printer, and we can perform cold forming operations,” as Xavier Teixidó Pont explains.

To realise this rationale, Teixidó has relied on Tornos and its machines since its earliest days. Teixidó still has around sixty cam-type machines, including R10s. It was one of the first customers to adopt the DECO, and the first DECO 10 dating back to 1997, is still running. The company now has several dozen Tornos CNC machines, including two EvoDECO 20 machines that replaced two old DECO 20s. “We have given Tornos a variety of challenges over the years,” states production manager Josep Colina Vidal. “It must be said that we have always enjoyed assistance from high quality contacts, both in Spain and Switzerland. The after-sales service from Tornos Spain is very fast, which we really appreciate.”

“However, it’s really Tornos’s machines which, when adapted for our production, make all the difference. We have a number of multi-spindle machines as well as our DECO, Delta and EvoDECO fleets. We have SAS 16, SAS 16.6 and BS 20.8 cam-type multi-spindles, MultiAlpha, MultiSigma and MultiDECO CNC machines and several recently acquired MultiSwiss 6×16 machines including 2 machines with Y axis.”

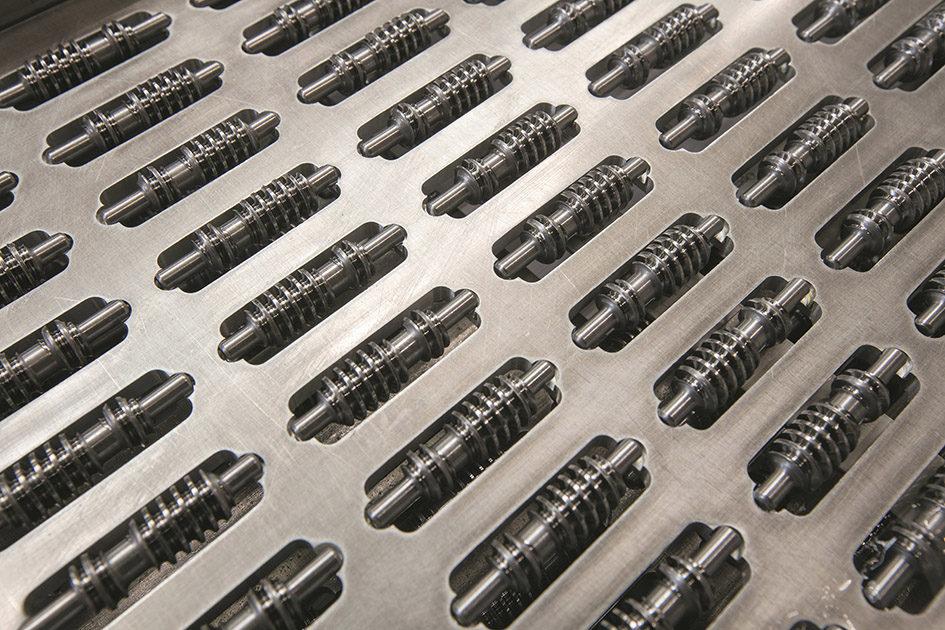

Components manufactured on Tornos machines

“These machines can exceed the specifications required of single-spindle models, offering stable, highly precise machining. And their six spindles make them extremely productive; we can produce far more parts per square metre. This means a MultiSwiss can easily replace three single-spindle turning machines.”

“It’s a very high-performance machine, and I think it’s fair to say we have been seduced by its performance. It also enables us to save time on setups, partly because we can avoid performing several identical setups on single-spindle turning machines, but primarily because the machine is highly ergonomic and changes can be performed very quickly. In addition, the machine is extremely compact thanks to its built-in peripherals, which is a big plus for us. To conclude, the MultiSwiss is an excellent partner for Teixidó, and the machine sits perfectly with our commitment to quality.”

“To guarantee perfect results, we have invested heavily in monitoring equipment; for example, we now have 23 measuring stations for automatically inspecting parts and a 3D measuring machine. Our philosophy is simple: customer satisfaction is our watchword, and to achieve it we rely on technology, quality and service. This has been our vision since the very beginning. It also guides Teixidó’s management in its relationships with employees and the environment. Training is a central pillar in Teixidó’s strategy for maintaining a high level of quality. The company has its own waste water purification station, as well as almost 600 m2 of solar panels installed on the roof of the factory. These factors combine to form Teixidó’s rationale: a model for success and unrivalled performance.”