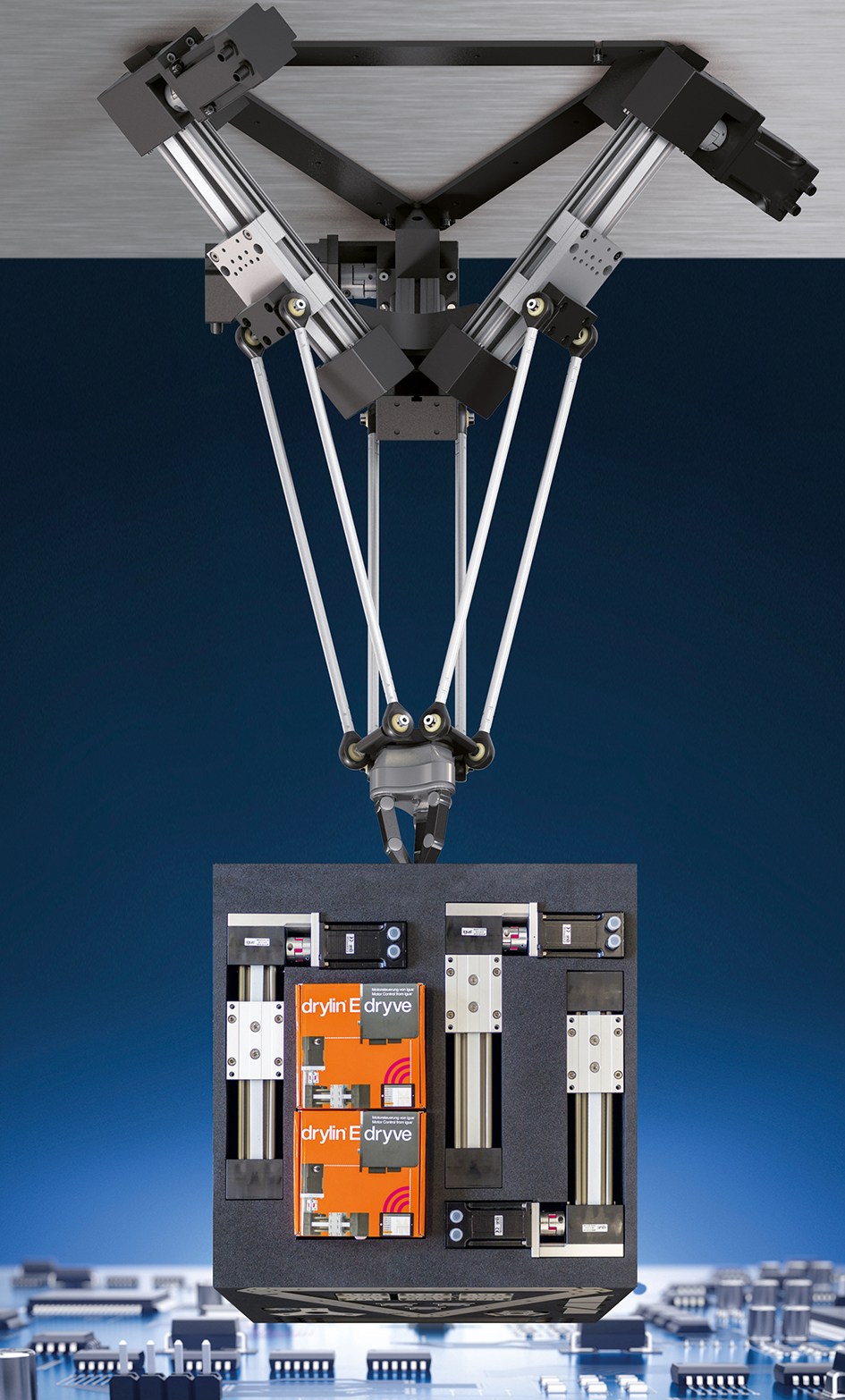

Based on three maintenance-free drylin ZLW toothed belt axes, the drylin delta robot is particularly suitable for simple assembly tasks, pick and place tasks, as well as applications in test & measurement.

In this week’s video, we see the rylin delta robot in a PCB assembly application. The three NEMA stepper motors and encoders driving the belt axes ensure a pick rate of at least 60 per minute with a precision of ±0.5 mm. The complete system, which is available directly from stock as a kit or delivered pre-assembled ready to install, has an installation space of up to 420 mm in diameter.

Its maintenance-free belt drive units, lubrication-free link rods, encoders and stepper motors combine to create a lightweight design. The typical ROI period for the drylin delta robot is estimated at just six months, this compares favourably to the industry’s rule-of-thumb target of two years.

Watch the video of the drylin delta robot in action below.

For more information about the drylin delta robot, please visit: www.igus.co.uk/deltaassembly or call igus directly on 01604 677240.

igus resources:

LiveChat with our technical team at igus.co.uk

Follow us at twitter.com/igusUK

Watch our videos at igus.co.uk/YouTube

Connect to us at igus.co.uk/Facebook

Read our blog at blog.igus.co.uk