The new direct diode laser (DDL) version of Mazak’s highly successful FABRI GEAR machine range is making its European debut at EuroBLECH 2018.

Mazak has fast-tracked the development of a DDL FG to complement the existing CO2 machine, due to the enormous productivity potential that laser users can derive from DDL technology.

The DDL is perfectly suited to cutting both thin and thick materials, and is also capable of cutting high reflectance material, such as copper and brass.

The new machine is equipped with a 4kW DDL resonator that can achieve a 20 per cent productivity improvement. This exceptional productivity is derived from its use of nitrogen; a reduction in piercing time, due to the use of a beam-on approach pierce, and an increase in cutting speed due to its higher light harvesting.

What’s more, the new DDL is capable of rapid traverse rates of 100m/min in the X-axis, 36m/min in the Y-axis and 30m/min in the Z-axis. If production is interrupted by an alarm, the Quick Program Restart function makes it possible to quickly restart the machine, reducing downtime.

In addition, running costs for the DDL machine are significantly reduced in comparison to CO2, due to lower resonator and chiller unit consumption, as well as there being no need for laser gas.

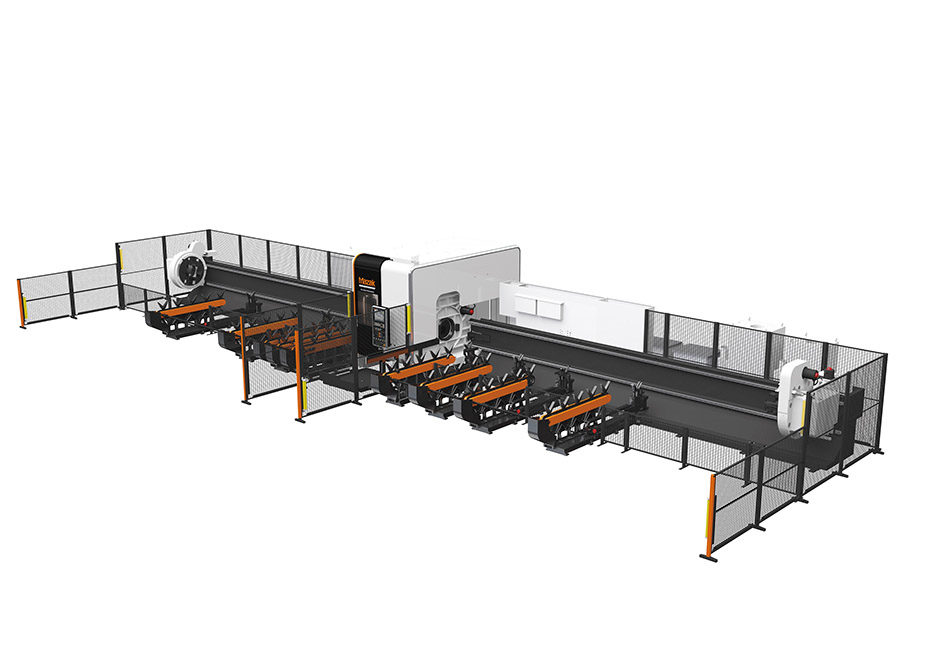

The machine is also equipped with a new 3D head, developed with an independent Z-axis and tapping units. Furthermore, new laser light shielding covers have been developed to cover both the loading and unloading sides of the machine.

Higher productivity is matched by the outstanding quality of the cut, with cutting quality for thick mild steel comparable to a CO2 laser.

The FABRI GEAR range has long been a favourite of the construction industry, due to its ability to cut round, square and rectangular pipe or tube often used in construction projects. The machine is controlled using the new Mazak FX CNC, which couples outstanding ease of operation with high productivity.