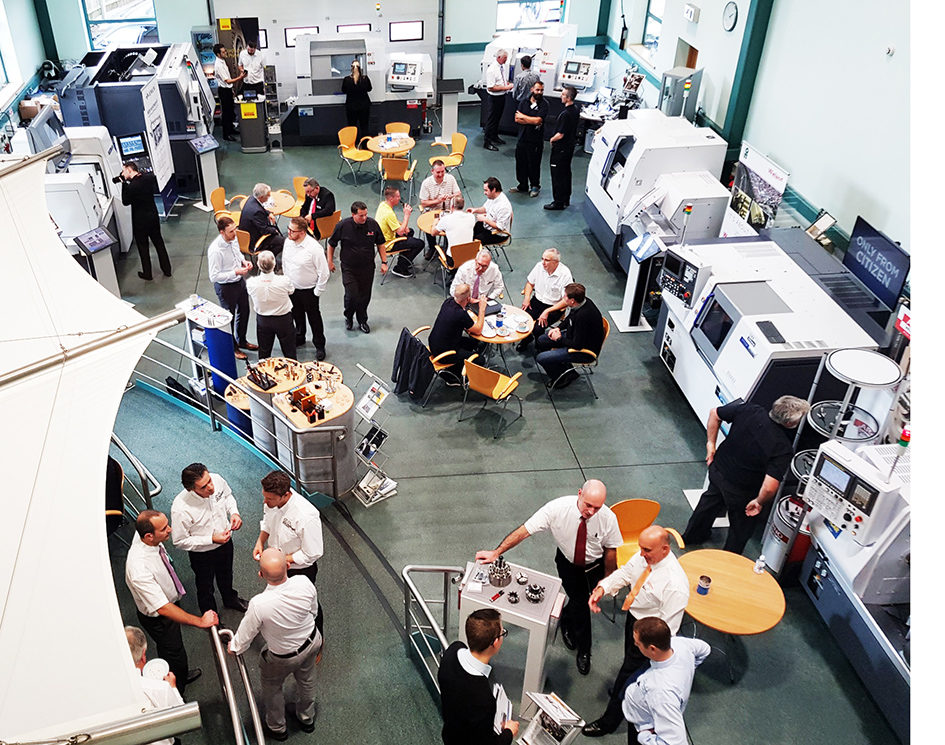

Citizen Machinery UK’s (CMUK) highly successful 3-day open house (16-18 October) immediately added a further 15 machines worth over £2.7 million to its existing order book of record sales involving some 100 Cincom sliding head and Miyano fixed-head turn-mill centres stretching into 2019.

Said Deputy Managing Director Darren Wilkins: “Over 350 people came through our doors over the three days with several bringing important future projects for us to investigate. This influx of interest was from both OEM and the sub-contract sectors and in particular involved oil and gas, aerospace and automotive companies.”

He followed on to confirm that following demonstrations and the ability for visitors to talk face-to-face with applications, service support and finance teams, the area sales engineers have a host of follow-ups and customer visits scheduled which will doubtless create future business well into the next year.

Citizen’s patented Low Frequency Vibration (LFV) programmable chip size machining technology was a major focus of attention adding to the ratio of seven out of every eight orders currently featuring its inclusion. This ratio was confirmed with the interest following the launch of the larger 38 mm capacity bar size of the Cincom L32-VIIILFV sliding head and the Miyano BNA-42GTYLFV moving headstock machines at the event.

From the demonstrations, visitors were able to appreciate how Citizen’s patented development of LFV is a fundamental in the design of the machine. Its ability to control chip size cannot reliably be achieved through simply adding a macro to the programming, an area Citizen revealed it had already investigated and rejected over a decade ago.

To maintain machining integrity the machine structure has to be upgraded for its overall rigidity, vibration damping and drive system performance in order to absorb the rapid oscillation of the cutting tool. As part of the cycle the tool movement creates, in effect, tens of micron sized air gaps, in synchronisation with the rotation of the spindle.

Added Mr Wilkins: “Both new and existing customers were also showing considerable interest in the Cincom ‘Superimposition’ operating control software which enables the simultaneous cutting with up to three tools on fixed head, two spindle, twin-turret, turn-mill centres. From the demonstrations it could be seen how the added flexibility to remove material from both ends of a component at the same time was able to significantly lower cycle times.

CMUK is also responsible for Citizen and Miyano product ranges in Africa, France, Italy, Middle East, Portugal and Spain which contribute to the current order book of over 100 machines. Indeed, Citizen’s overall European deliveries in 2018 will exceed 1,200 units establishing the company as market leader for Swiss-type sliding head machines as well as the leading brand for providing bar turning solutions. As a result, Europe significantly contributed to Citizen’s worldwide production output of 6,500 machines this year.