A dental laboratory used specialist WorkNC Dental software in a pioneering project with newly-developed material to create a major prosthesis for a patient suffering from Bruxism.

The patient had lost almost all his teeth to the tooth grinding and jaw clenching condition. The doctor proposed fixed metal-ceramic bridges made from a conventional cast Co-Cr stellite, and a removable prosthesis constructed from a relatively new material, PEEK.

PEEK is a biocompatible and tasteless flexible resin, making it ideal for dental work such as prosthetic bases, primary and secondary constructions, and metal-free superstructures, along with crown and bridge restorations.

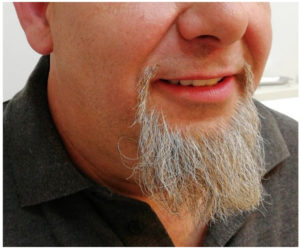

Dr Miquel Furriols carried out the project at Laboratorio Dental Tamayo S.L. in Barcelona, and says he will definitely be using PEEK again. “It provides a better level of comfort because of its minimal weight and extreme low thermal conductivity. It’s also non-allergenic, resistant to plaque, and is tasteless.” Another benefit is the difference in appearance compared to Co-Cr Stellite. “PEEK is disguised much more to be pink, so looks like natural gums.”

And he says the overall result, combining the use of materials with the most advanced technology in all phases of planning, design and CAM, is both functional and aesthetic.

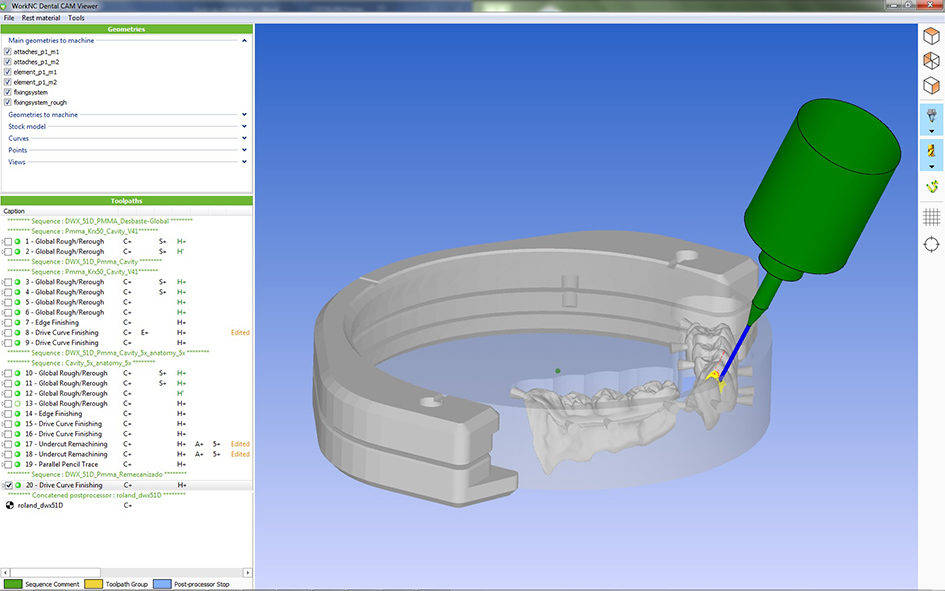

That latter point of CAM, is taken up by the laboratory’s Prosthesis and CAD/CAM Technician, Javier Martinez Ordoñez. “The precision of our dental prostheses has to be less than 0.05mm, which we can guarantee with complete confidence, as WorkNC produces fast and accurate toolpaths from our Exocad CAD files.”

WorkNC Dental programs their Roland DWX-51D 5-axis machine tool for all CNC milling of their fixed and removal prostheses, machined in a variety of materials including Presintered Co-Cr, PEEK, Zirconium and PMMA.

“To successfully mill a stellite in PEEK had been an ongoing challenge to us. But WorkNC Dental provides us with an automatic, specific milling sequence which optimises the machine. The automatic process is a vital tool for us. To be able to configure our standard components and apply automatic processes saves considerable time. Thanks to WorkNC Dental enabling us to tackle even the most complex parts we’ve extended the catalogue of prostheses we offer. It means we can edit and adapt all milling conditions, materials and tools, and guarantees top quality in the milling process.”

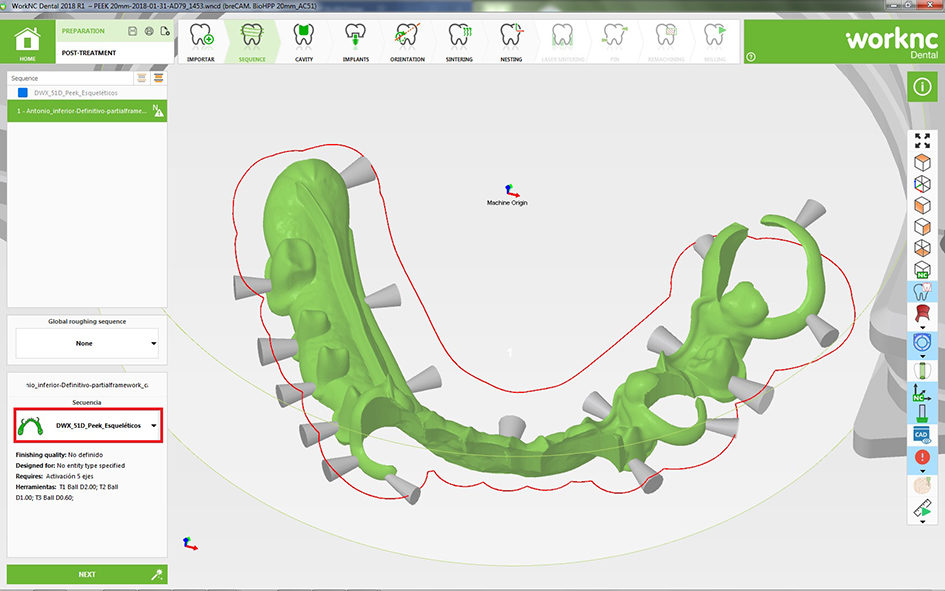

The first part of the procedure for the Bruxism patient was to design the lower stellite in Exocad, and then import the file into WorkNC Dental for programming the toolpaths. Running the simulation showed that the toolpaths for the skeleton were accurate, and the material was cut. For milling the PMMA bridges to be placed in the skeleton, WorkNC Dental’s roughing sequence optimised the 5-axis machining process, and re-machined the space between the pieces to improve the finish quality. He says the result was that the milled pieces fit together perfectly…both the stellite in the plaster model, and the crowns and bridges in the stellite.

Javier Martinez Ordoñez explains in detail how the above procedure was carried out once the CAD files had been complete in Exocad. “WorkNC Dental’s automatic process was the same for the stellite and the crowns and bridges, and even though it was a big project the programming was carried out with just a few clicks.

“First of all, in the Home menu we simply chose the configuration, blank, material and machine, and saved it in a file. Then we chose the STL file we wanted to mill by dragging and dropping it. Once we’d selected the file we applied the prosthesis definition. In this case it was defined with a stellite…and WorkNC Dental simply applied the right toolpath sequences to it. The next step was to choose the blank. WorkNC Dental showed us the X, Y, Z dimensions of the part, and the disk for fitting.

“Once the job was fully configured, we launched it to the Batch Manager which calculated the CNC program in another screen, leaving WorkNC Dental ready to work on another project. While the general configuration, including the position and number of support pins, and nesting the parts in the blank, was all done automatically, the software also gave us the option of editing the basic parameters.”

Before investing in the software in 2016, Laboratorio Dental Tamayo used a CAD/CAM system which did not allow them to change materials, tools or toolpaths once the process was underway. “We saw WorkNC Dental’s potential in helping us to evolve, and develop a wider range of prostheses.”

Vero Software’s Iberian operation worked with the laboratory to ensure the software was perfect for their specific needs. “At the beginning of the relationship Vero’s engineers developed a protocol for introducing it into our system, and it’s been perfect for us since day one.”

Concluding, Javier Martinez Ordoñez says: “WorkNC is a tool that lets us optimise our milling operation. It’s a core part of our CAD/CAM process. We could change our CNC machine tools with no problem, but we couldn’t change WorkNC Dental and achieve the same results.”