GT Grinding’s continual quest to meet a growing order book, and to improve service delivery levels in the manufacture of special-purpose tooling as well as tool regrinds for customers across the UK and in all industry sectors, has led the tooling specialist to invest in a Walter Helitronic Power tool grinder.

Supplied by Walter Ewag UK, a member of the United Grinding Group, the machine is capable of processing rotary tools from 3 mm to 320 mm diameters and up to 350 mm long.

Complementing three other Helitronic machines at the company’s Oldham site, the new Power is equipped with an Eco Loader and wheelchanger, as well as the latest version of Walter’s Tool Studio programming software, to ensure that GT Grinding “stays head in the design, modification and grinding of rotary tooling”, according to Works Manager Andy Cooper.

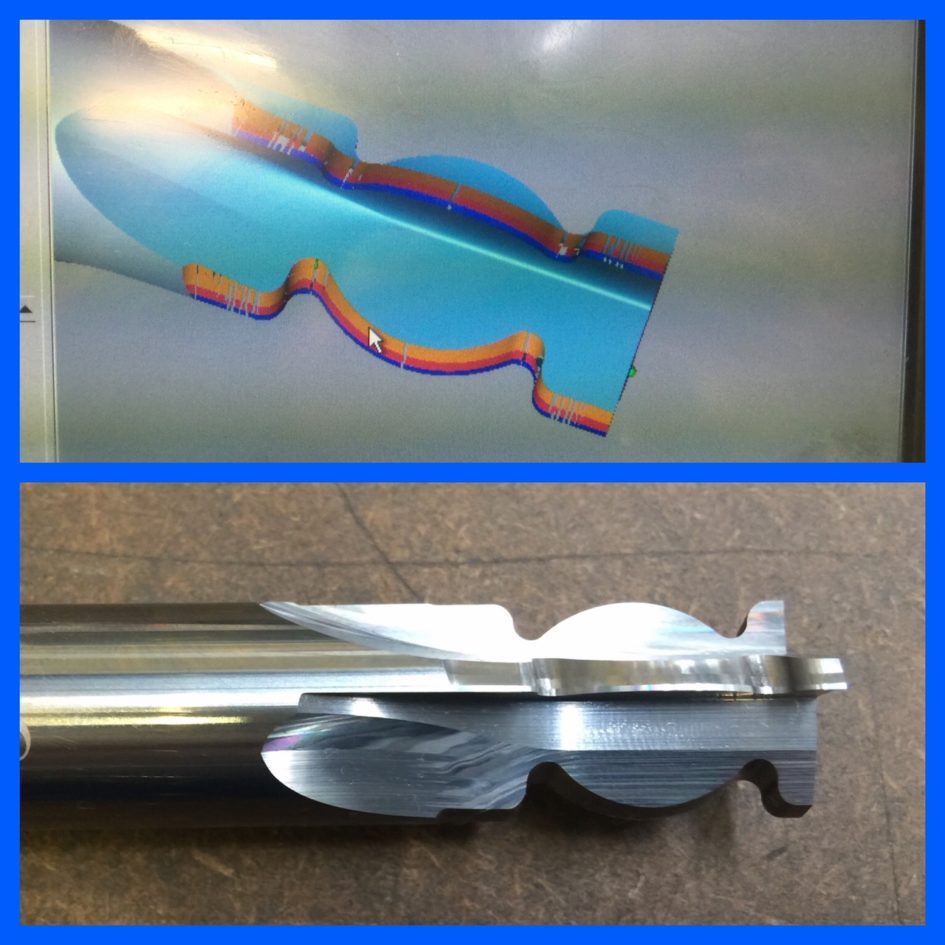

He adds: “This latest machine will undoubtedly also help us to make further inroads into our manufacturing and regrinding operation, especially of routers for the woodworking and plastics industries. And the Tool Studio software will play a key role, too.”

With integrated Wizard technology for ease of use, Tool Studio 3 includes a host of new routines for ‘what you see you can grind’ fast tool production simulation, parameter changes and operation for Helitronic Power users. Included is new functionality for:

Thread milling cutters – diameter/flank grinding and OD grinding;

Pocket extensions – import and grind DXF pocket shapes;

Cut-off operations – compensating for worn wheels;

Probing and alignment of asymmetrical flats – more functionality to define probing points/probe the exact position for perfect alignment;

In-process wheel measurement inside the machine;

Core compensation for long tools – core parameter and tolerance band;

Automatic machine axis referencing – using setting disc with electrical isolator; and

Coolant hole detection with camera.

When such powerful yet such easy-to-use software is combined with the benefits of automatic non-stop production via the Eco Loader – which is located on the machine work table and can accommodate 20 tools as standard and up to 165 tools in the Eco Loader Plus configuration – and the integrated wheelchanger (up to eight wheels), then the multi-axis Helitronic Power is a formidable production ally in the war against non-productive time.

In GT Grinding’s case, this includes the machining of solid carbide and HSS tools such as special form cutters and slitters as well as ‘conventional’ drills, milling cutters and reamers.

Mr Cooper says he and GT Grinding has a long-established history (more than 30 years) of using Walter tool grinders and while he “always visits the biennial GrindTec exhibition to keep track of all machine developments”, he always returns to Walter.

“In addition to being machines that actually do what they say they can, the fact is that Walter Ewag UK provides a great level of service back-up. Knowing that any issues with the machines and the software can be addressed very quickly is a great weight off my mind when my main aim is to get quality products out of the door!”

GT Grinding’s latest Walter Helitronic tool grinder will undoubtedly help the company “make further inroads into our manufacturing and regrinding operation, especially of routers for the woodworking and plastics industries”