A Doosan Machine Tools NHP-6300, 4-axis HMC equipped with 5ME®Cryogenics headed to Milling Precision Tool Corp. to machine titanium aerospace components.

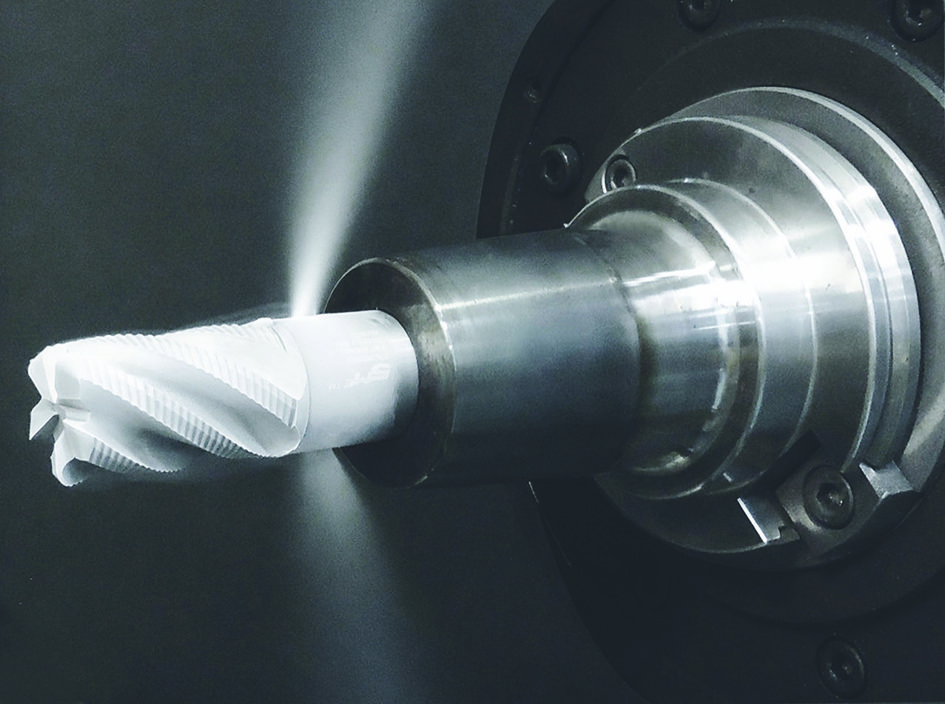

5ME and strategic partner Doosan Machine Tools started IMTS 2018 in a big way – with the sale of a Doosan Horizontal Machining Center (HMC) equipped with 5ME Cryogenics sold by Doosan distributor Machine Tool Specialties. The Doosan NHP-6300, 4-axis HMC will process titanium 6Al4V components in Milling Precision Tool Corp’s Wichita, KS facility. Machining with the 5ME Cryogenics equipped HMC increased productivity by 30 percent compared to traditional coolant machining. “This is what IMTS is all about – coming together to develop and deliver the best manufacturing technology,” said Bill Horwarth, President, 5ME. “Our partnerships make the evolution to cryogenic machining possible, from machine tool, to our patented internal liquid nitrogen (LN2) machining technology, to cryogenic tooling. We have a total cryogenic solution ready for the shop floor. This is the first 5ME Cryogenics enabled machine tool sold into the ‘Aerospace Capital’ of Wichita, Kansas, and we see big opportunities for cryogenic machining in that region.”

The Doosan NHP-6300 HMC has X-Y-Z travel of 41.3’ X 35.4’ x 39.4”, a 24.8” pallet and a feed rate of 1,986 IPM. The CAT50 BigPlus spindle is 60 hp, 10,000 RPM with 443 ft-lb torque. “Our machine tools are built for massive metal removal, with the increased productivity from 5ME Cryogenics, our machines are set for maximized profitability,” said Jim Shiner, Director of Marketing and Sales for Doosan Machine Tool. “The 5ME Cryogenics option really optimizes the machining performance of hard-to-machine materials, like titanium.”

Milling Precision Tool Corp also saw an increase in part quality with a much smaller environmental footprint. “We’re working to differentiate ourselves and better support the supply chain in Wichita, KS”,” said Mike Craig, Co-owner Milling Precision Tool. “We’re excited to be the first business in the Wichita market with cryogenic capability.”

5ME Cryogenic Machining Technology has a large presence at IMTS 2018. The company has partnered with machine tool makers and tooling manufacturers to demonstrate methods for better metal cutting and shop floor monitoring. 5ME Cryogenic machining demonstrations are in the Doosan Machine Tools America (339100), Fullerton Tool Company (432123), Star SU (432258), and BENZ, Inc. (432445) booths.

5ME Cryogenics has revolutionizedmachining, using through-spindle, through-tool liquid nitrogen (LN2) delivery to mitigate heat produced during cutting. Cryogenics offers many benefits over conventional coolants in efficiency and environmental friendliness. Useful for difficult-to-machine materials, cryogenic machining boasts an incredible -400° cooling advantage, which allows for increased material removal rates (MRR) and tool life. 5ME Cryogenic Machining Technology is offered as a new machine option or can also be retrofitted to almost any machine tool.

For more information visit www.5ME.com

contact a 5ME Efficiency Expert by emailing info@5ME.com

or Tel: (+)1 513 719 1600